Concrete mixer

A technology of concrete mixer and fixed plate, applied in cement mixing device, mechanical equipment, engine components, etc., can solve the problems of overheating transmission and insufficient lubricating oil, and achieve the effect of automatic injection of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

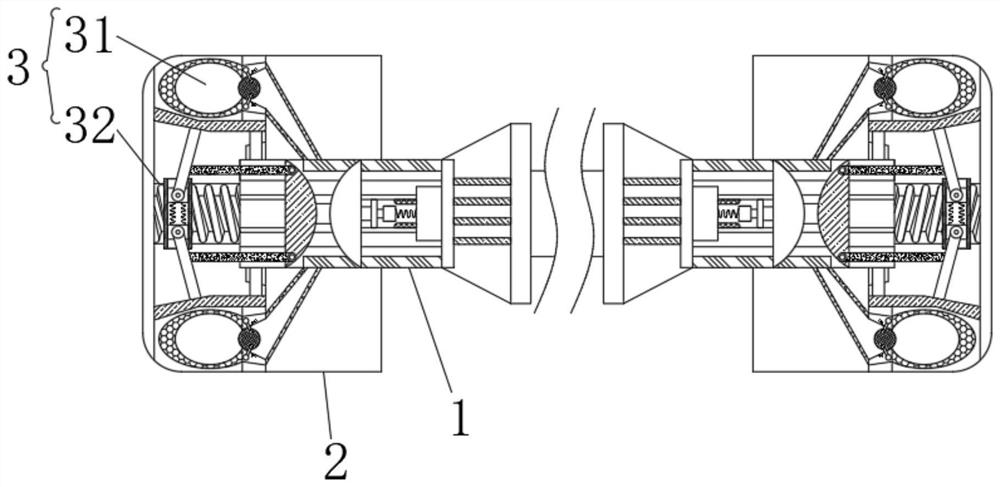

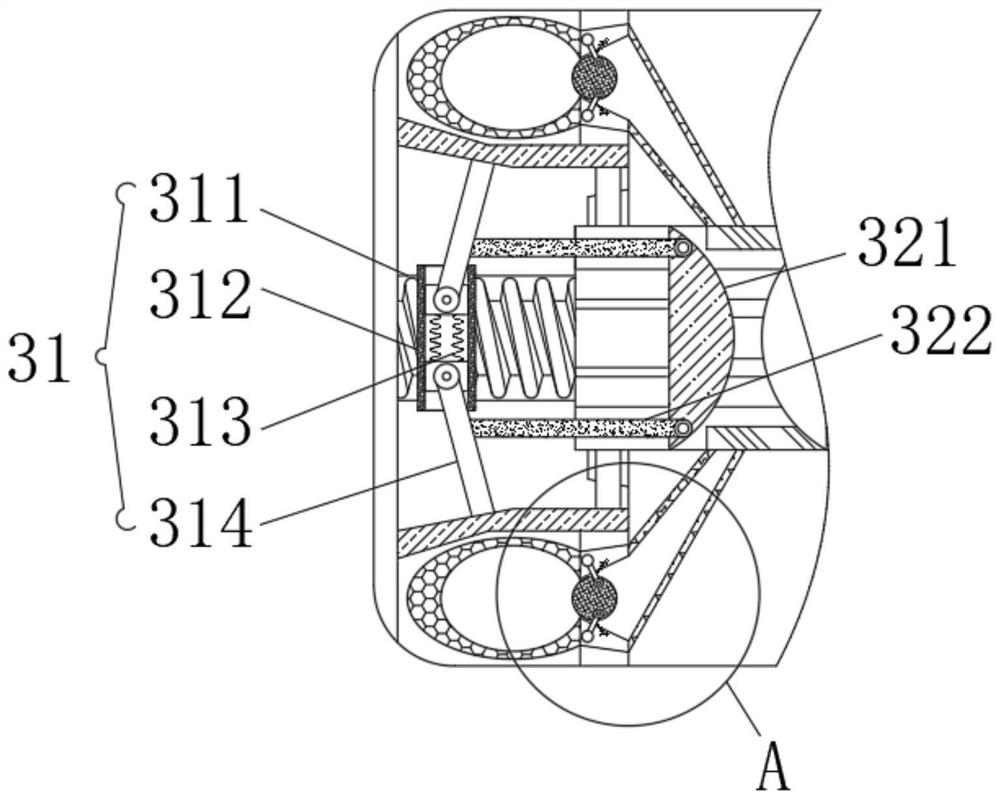

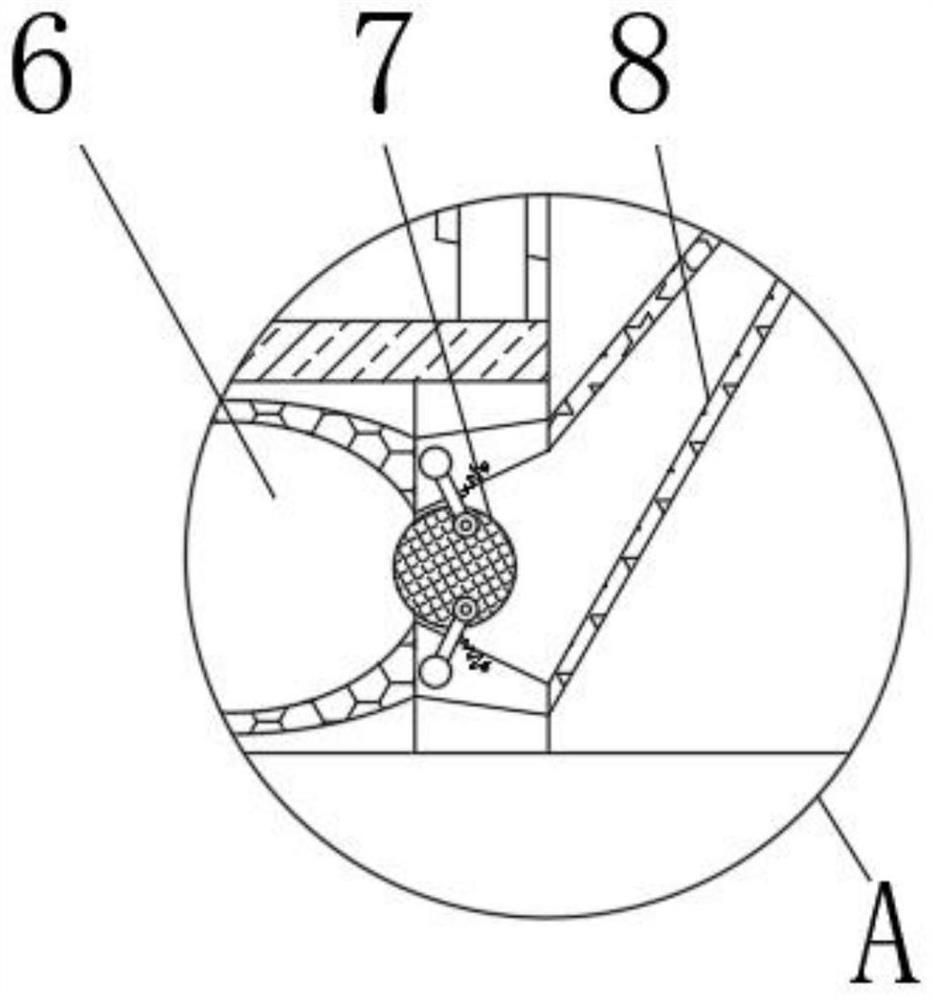

[0026] see Figure 1-3 , a concrete mixer, comprising a fixed plate 1, a fixed frame 2 is fixedly installed on the opposite side of the fixed plate 1, the upper and lower ends of the fixed frame 2 are fixedly installed with a placement plate 5, and the interior of the placement plate 5 is fixedly installed There is a storage chamber 6, a one-way valve 7 is fixedly installed on the opposite surface of the storage chamber 6, a feeding pipe 8 is fixedly installed between the one-way valve 7 and the fixed plate 1, and an injection mechanism 3 is fixedly installed inside the fixed frame 2, The injection mechanism 3 includes: a reciprocating mechanism 31 and a limiting mechanism 32, and the reciprocating mechanism 31 includes: a rotating screw rod 311, on which a sliding block 312 is meshed and connected, and the inside of the sliding block 312 is slidably connected with a support rod 314 through a return spring 313, fixed The interior of the board 1 is fixedly equipped with an earl...

Embodiment 2

[0028] see figure 1 , 4 , a concrete mixer, comprising a fixed plate 1, a fixed frame 2 is fixedly installed on the opposite side of the fixed plate 1, an injection mechanism 3 is fixedly installed inside the fixed frame 2, an early warning mechanism 4 is fixedly installed inside the fixed plate 1, the early warning Mechanism 4 includes: energization plate 41, the inside of energization plate 41 is slidably connected with electric shock block 43 through connection spring 42, the connection relationship between electric shock block 43 and expansion bag 321 is fixed connection, and the upper and lower ends of fixed plate 1 are provided with The oil inlet pipe 9, the interior of the oil inlet pipe 9 and the feeding pipe 8 are designed to be connected, and the transmission mechanism 10 is fixedly installed on the opposite surface of the fixed plate 1. When the internal temperature of the fixed plate 1 rises, the volume of the expansion bag 321 It will continue to grow larger, so ...

Embodiment 3

[0030] see Figure 1-4 , a concrete mixer, comprising a fixed plate 1, a fixed frame 2 is fixedly installed on the opposite side of the fixed plate 1, the upper and lower ends of the fixed frame 2 are fixedly installed with a placement plate 5, and the interior of the placement plate 5 is fixedly installed There is a storage chamber 6, a one-way valve 7 is fixedly installed on the opposite surface of the storage chamber 6, a feeding pipe 8 is fixedly installed between the one-way valve 7 and the fixed plate 1, and an injection mechanism 3 is fixedly installed inside the fixed frame 2, The injection mechanism 3 includes: a reciprocating mechanism 31 and a limiting mechanism 32, and the reciprocating mechanism 31 includes: a rotating screw rod 311, on which a sliding block 312 is meshed and connected, and the inside of the sliding block 312 is slidably connected with a support rod 314 through a return spring 313, fixed The interior of the board 1 is fixedly equipped with an earl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com