Furniture plate surface waxing device capable of fixing wax block

A technology for furniture and boards, which is applied in the direction of grinding drive devices, machine tools for surface polishing, grinding/polishing safety devices, etc. It can solve the problems that the board cannot be polished, the surface of the board cannot be waxed and wiped, and the wax block cannot be fixed. Guarantee the effect of waxing, good fixation, and the effect of ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

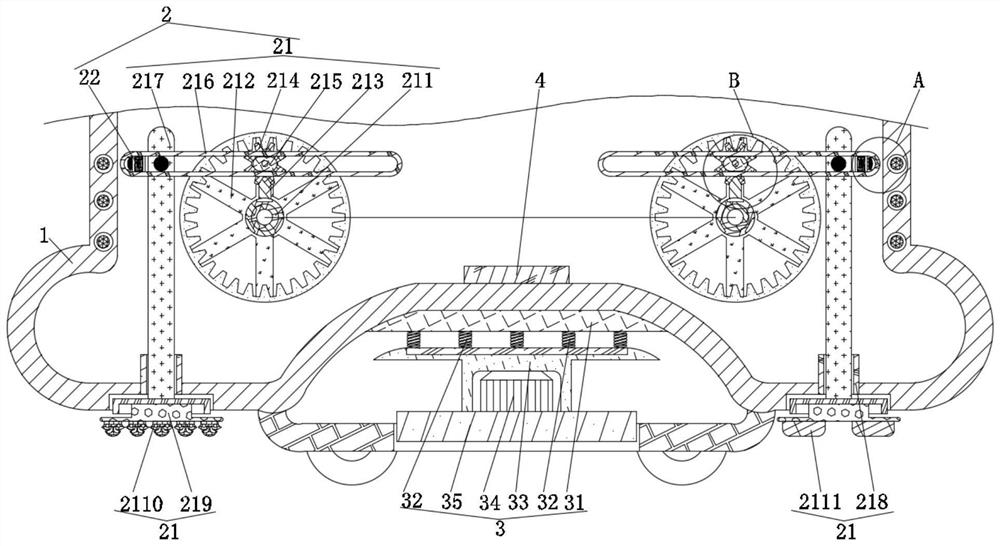

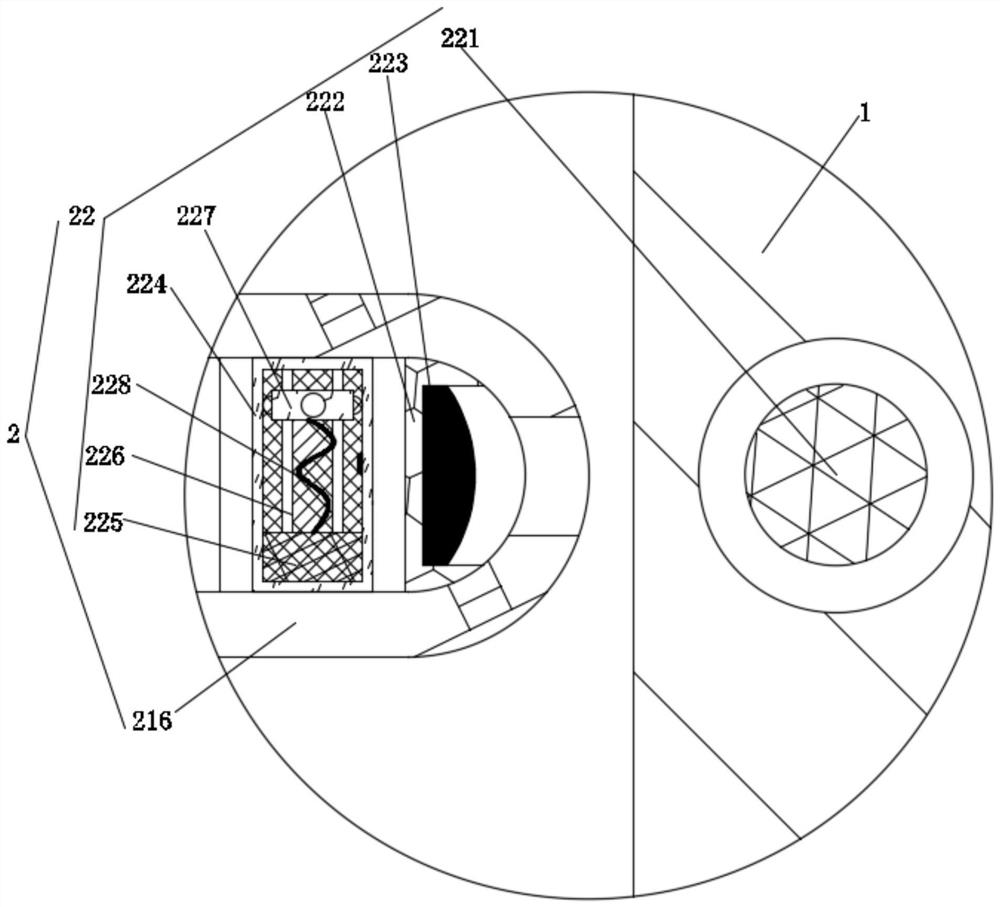

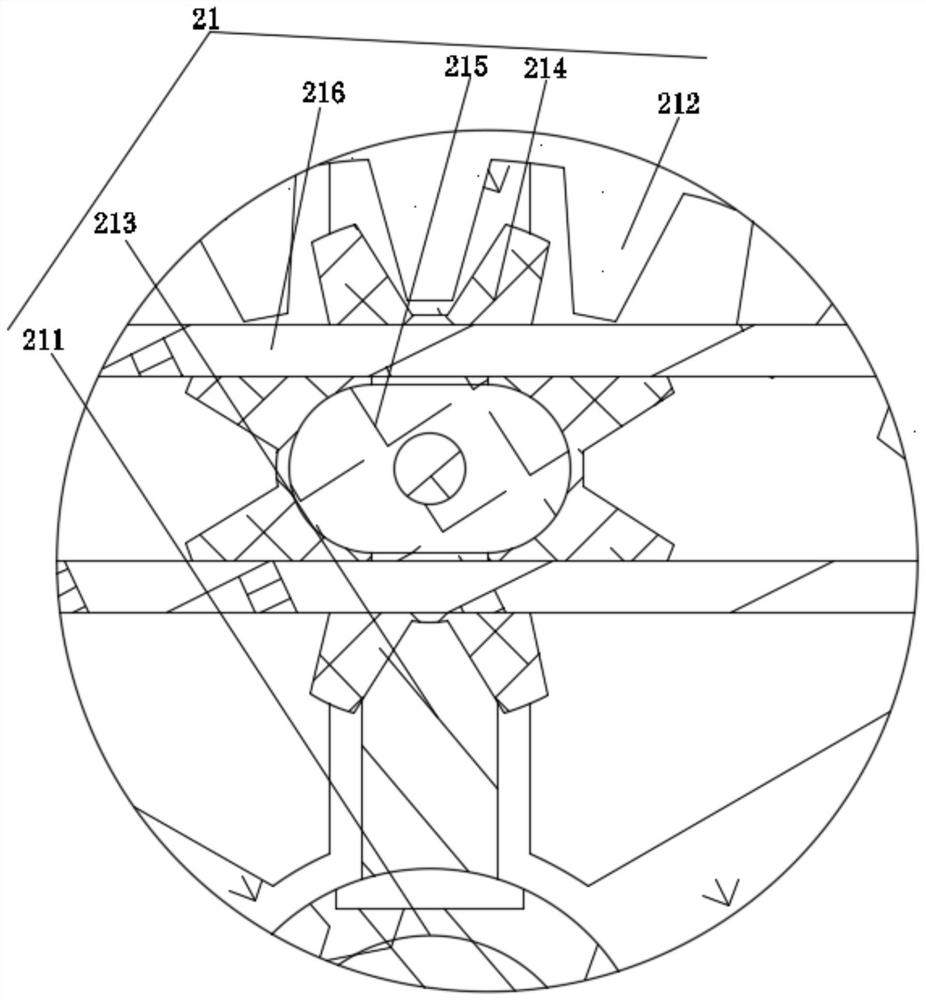

[0028] see Figure 1-3 , a furniture board surface waxing device capable of fixing wax blocks, comprising a housing 1, a fixed depth grinding mechanism 2 is movably connected to the inside of the housing 1, and the fixed depth grinding mechanism 2 includes a moving assembly 21.

[0029] The moving assembly 21 comprises a motor one 211, a ring gear 212, a rotating rod 213, a movable gear 214, a limit block 215, a long rod 216, a push rod 217, a short rail 218, a support block 219, a grinder 2110, a cleaning block 2111, a motor One 211 is fixedly connected to the inside of the casing 1, the ring gear 212 is fixedly connected to the inside of the casing 1, the rotating rod 213 is fixedly connected to the outside of the motor one 211, the movable gear 214 is rotatably connected to the outside of the rotating rod 213, and the limit block 215 rotates Connected to the outside of the movable gear 214, the long rod 216 is slidably connected to the outside of the limit block 215, the pu...

Embodiment 2

[0034] see figure 1 , 4 5. A furniture surface waxing device capable of fixing wax blocks, comprising a shell 1, and a fixed waxing mechanism 3 is movably connected to the inside of the shell 1.

[0035] Fixed waxing mechanism 3 comprises electromagnet 2 31, support spring 32, top plate 33, motor 2 34, support shell 35, rotating strut 36, top block 37, limit shell 38, clamping assembly 39, and electromagnet 2 31 is fixed Connected to the inside of the shell 1, the support spring 32 is fixedly connected to the outside of the electromagnet 2 31, the top plate 33 is fixedly connected to the outside of the support spring 32, the motor 2 34 is fixedly connected to the inside of the top plate 33, and the support shell 35 is fixedly connected to the top plate 33 The outside of the rotating strut 36 is fixedly connected to the outside of the second motor 34, the top block 37 is rotatably connected to the outside of the rotating strut 36, the limiting shell 38 is rotatably connected t...

Embodiment 3

[0038] see Figure 1-5 , a furniture board surface waxing device capable of fixing wax blocks, comprising a housing 1, a fixed depth grinding mechanism 2 is movably connected to the inside of the housing 1, and the fixed depth grinding mechanism 2 includes a moving assembly 21.

[0039] The moving assembly 21 comprises a motor one 211, a ring gear 212, a rotating rod 213, a movable gear 214, a limit block 215, a long rod 216, a push rod 217, a short rail 218, a support block 219, a grinder 2110, a cleaning block 2111, a motor One 211 is fixedly connected to the inside of the shell 1, the ring gear 212 is fixedly connected to the inside of the shell 1, the rotating rod 213 is fixedly connected to the outside of the motor one 211, the movable gear 214 is rotatably connected to the outside of the rotating rod 213, and the limit block 215 rotates Connected to the outside of the movable gear 214, the long rod 216 is slidably connected to the outside of the limit block 215, the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com