Automatic tea impurity removing device and production line

A technology of rejecting device and production line, which is applied in tea treatment before extraction, chemical instruments and methods, solid separation, etc., can solve problems such as poor effect, high tea crushing rate, and high cost of manual picking, so as to reduce the cost of picking , Safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

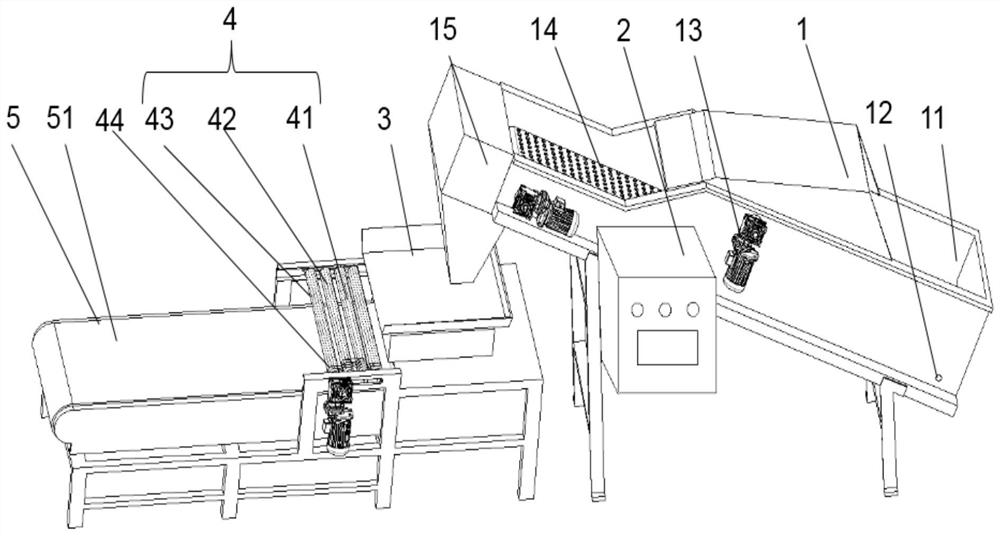

[0084] Automatic tea processing production line such as figure 1 As shown, the angle between the feeding conveyor belt and the horizontal direction is 12 degrees, the speed of the feeding conveyor belt is 0.5m / s, the speed of the collecting unit conveyor belt is 0.5m / s, and there are 4 debris removal rollers. The spacing is 51.5cm, the rotation speed is 250r / min, the surface of the roller is wrapped with adhesive cloth, and the distribution density of hooks on the adhesive cloth is 25 / cm 2 , the height of the hook is 2.5 mm, and the ratio of the width of the debris removal area to the width of the roller is 1:1. Use this production line to remove impurities in Pu-erh sun-dried green tea.

[0085] Two workers check the removal effect of soft and fluffy debris such as hair and woven bags beside the collection conveyor belt, and take the form of random inspection. If there are more than 3 debris in 30kg of raw materials, re-picking is required. The inspection result is: there i...

Embodiment 2

[0087] Automatic tea processing production line such as figure 1 As shown, the distribution density of adhesive cloth hooks is 25 pcs / cm 2 , the height of the hook is 3.5mm, and other parameters are the same as in Example 1.

[0088] Use this production line to remove impurities in Pu-erh sun-dried green tea.

[0089] Two workers check the removal effect of soft and fluffy debris such as hair and woven bags beside the collection conveyor belt, and take the form of random inspection. If there are more than 3 debris in 30kg of raw materials, re-picking is required. The inspection result is: there are 2 sundries in 30kg of raw materials, and the result meets the standard.

Embodiment 3

[0091] Automatic tea processing production line such as figure 1 As shown, the distribution density of pasting cloth hooks is 36 pcs / cm 2 , the height of the hook is 3.5mm, and other parameters are the same as in Example 1.

[0092] Use this production line to remove impurities in Pu-erh sun-dried green tea.

[0093] Two workers check the removal effect of soft and fluffy debris such as hair and woven bags beside the collection conveyor belt, and take the form of random inspection. If there are more than 3 debris in 30kg of raw materials, re-picking is required. The inspection result is: there are 3 sundries in the 30kg raw material, and the result meets the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com