P-doped g-C3N4/MoP catalyst for hydrogen production through water photolysis, and preparation method thereof

A technology of photocatalytic hydrogen production and photocatalysis, which is applied in the field of photocatalysis, can solve the problems of limiting the improvement of photocatalytic performance, low migration rate of photogenerated carriers, and high preparation temperature, and achieves excellent photocatalytic water decomposition hydrogen production performance , easy large-scale production, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) P-doped g-C 3 N 4 / Preparation of MoP photocatalyst

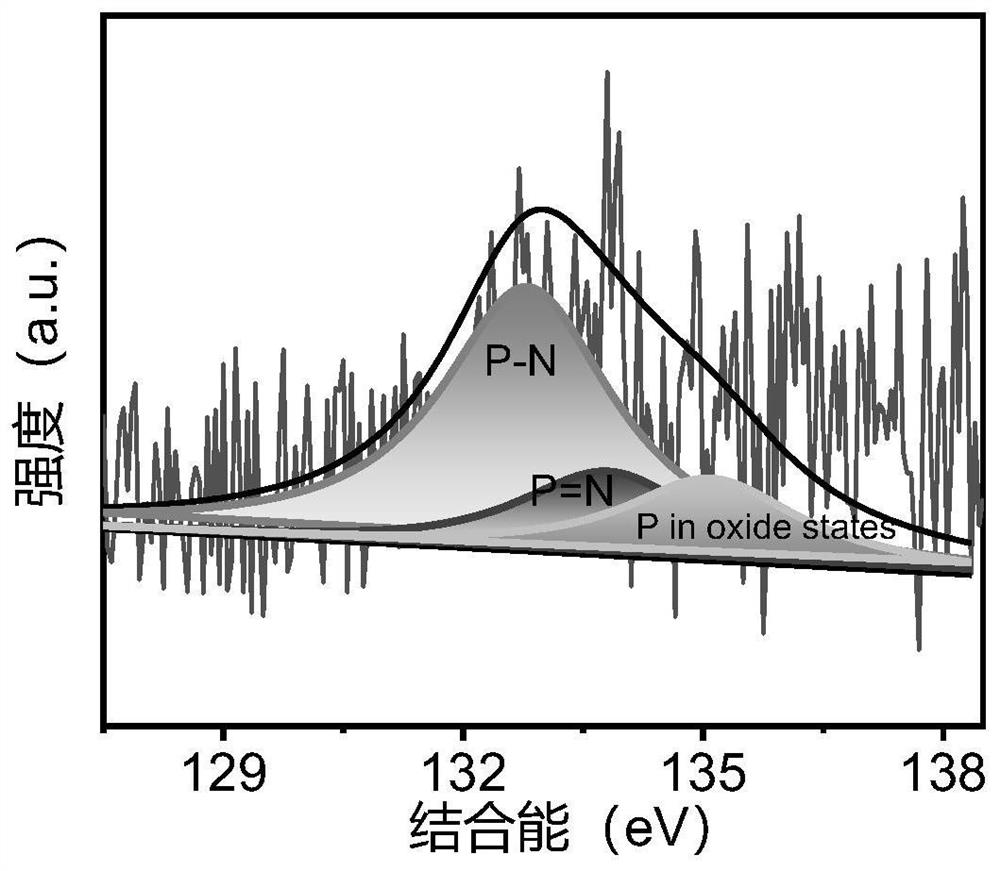

[0023] First, weigh 0.9g NaH 2 PO 2 ·H 2 O and 1g g-C 3 N 4 , transfer the two to a 50mL ball mill tank, add balls according to the ball-to-material ratio of 13:1, set the ball mill speed to 1000rpm, and high-energy ball mill for 1 hour, then wash with deionized water and ethanol successively, suction filter, and Vacuum drying at 60 °C yielded P-doped g-C 3 N 4 , see its P 2p high-resolution XPS spectrum in the instruction manual figure 1 . From figure 1 It can be seen that obvious XPS peaks corresponding to P-N and P=N bonds can be observed at the binding energies of 132.8 and 133.8 eV, confirming that P atoms were successfully doped into g-C 3 N 4 in the skeleton.

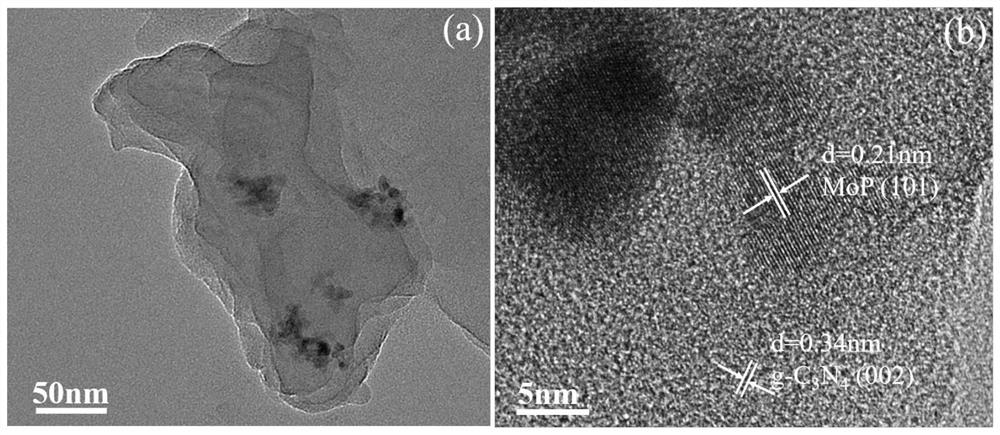

[0024] Then, weigh 1g of self-made P-doped g-C 3 N 4 and 0.05g MoP, mixed and transferred to a 50mL ball mill jar, adding grinding balls according to the ball-to-material ratio of 22.8:1, and ball milling at a speed of 1000rpm for 1 ...

Embodiment 2

[0030] (1) P-doped g-C 3 N 4 / Preparation of MoP photocatalyst

[0031] At first by the step (1) in the embodiment 1, make the g-C of P doping 3 N 4 , and then weigh 1g of self-made P-doped g-C 3 N 4 and 0.03g MoP, mixed and transferred to a 50mL ball mill jar, adding balls according to the ball-to-material ratio of 23.3:1, and ball milling at a speed of 1000rpm for 1 hour to obtain P-doped g-C 3 N 4 / MoP photocatalyst.

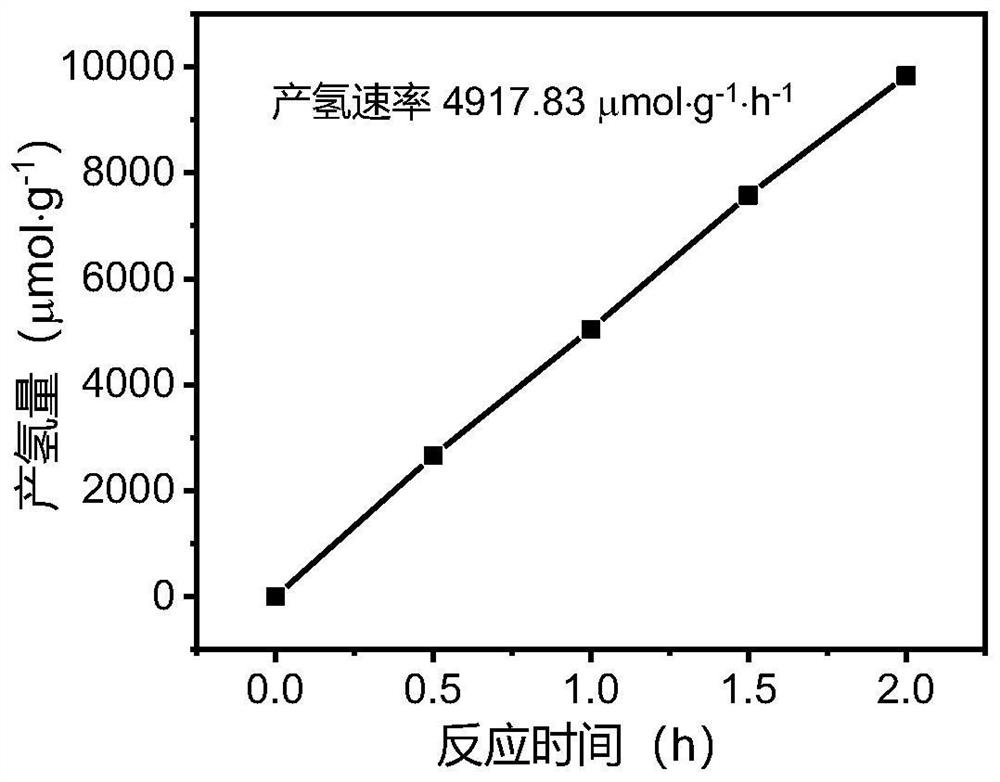

[0032] (2) According to step (2) in Example 1, the photocatalytic water splitting hydrogen production performance test is carried out, and the hydrogen production performance diagram of the obtained split water is shown in the appendix of the specification Figure 5 . From Figure 5 It can be seen that the hydrogen production rate of the photocatalyst is 4711.65 μmol g -1 h -1 .

[0033] (3) P-doped g-C 3 N 4 Cyclic stability test of MoP photocatalyst for water splitting and hydrogen production

[0034] According to the step (3) in the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com