Water spraying water film type wet dust removal system

A technology of wet dust removal and water film, which is applied in the field of dust removal, can solve the problems of high cleaning requirements at the mesh, easy blockage of the dust removal system, and difficulty in dust sedimentation, so as to avoid hidden dangers in production safety, improve automatic cleaning capabilities, and improve The effect of cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

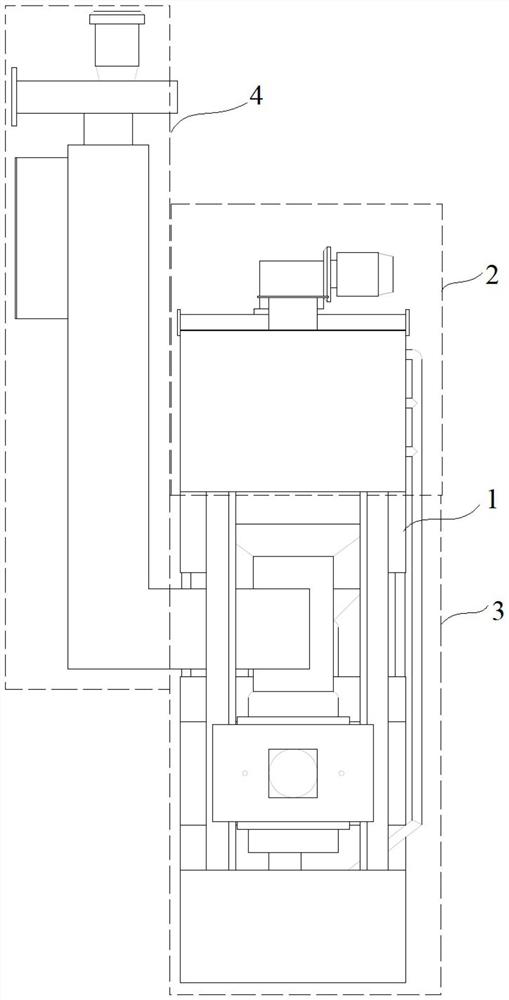

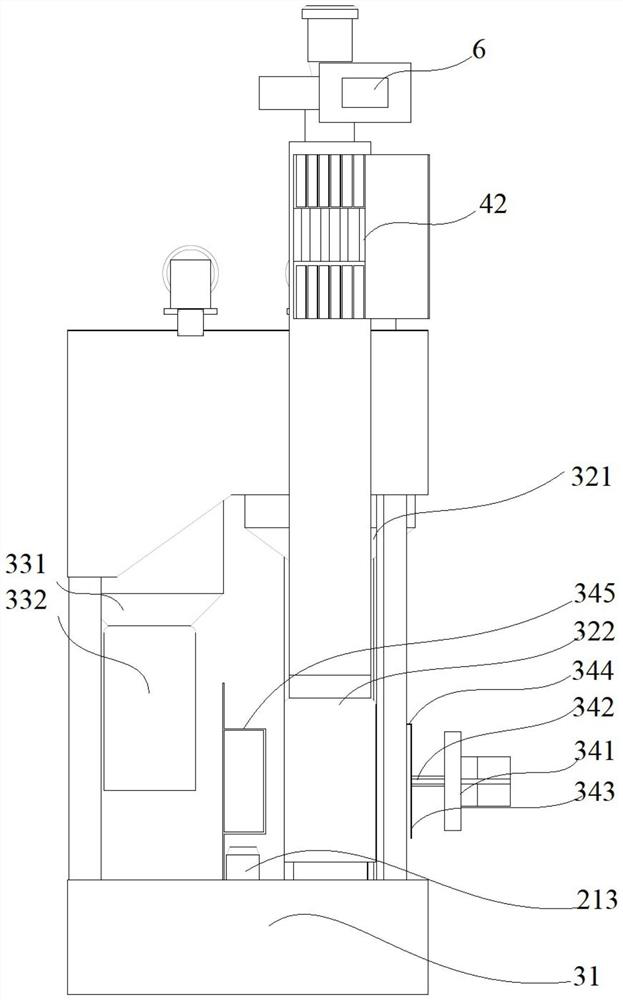

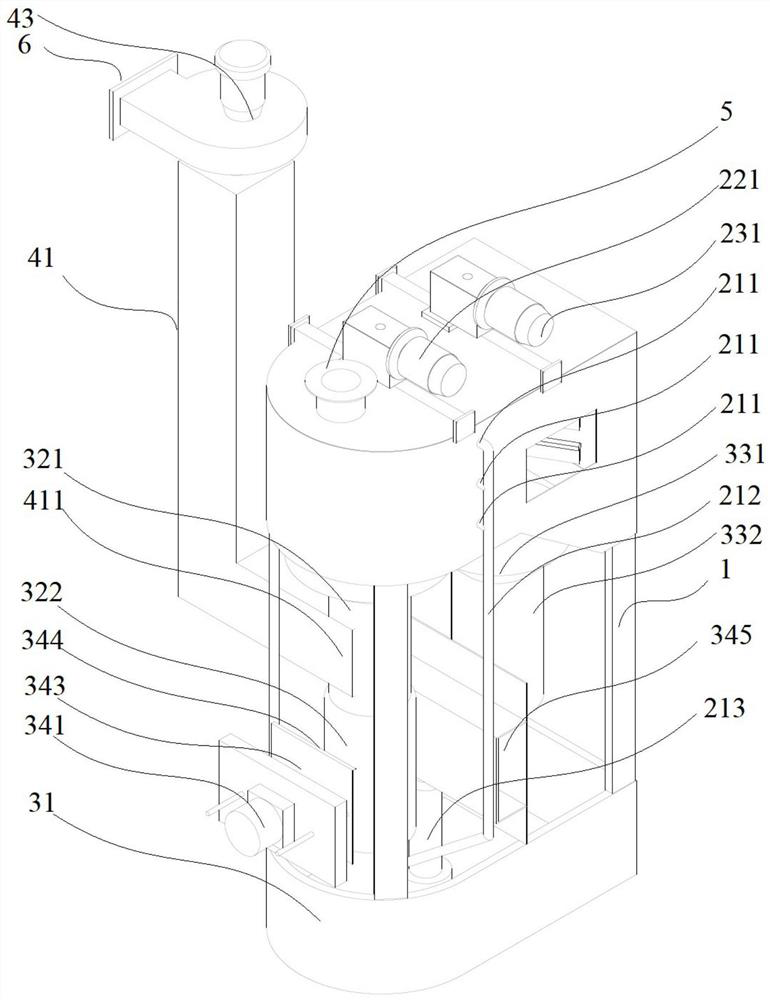

[0034] The invention provides a water spray membrane wet dust removal system, which mainly includes: a box body, a dust filter area, a dust collection area and a gas demisting area. The box body is a structure similar to a box, and the dust filter area and the dust collection area are encapsulated Inside, at the same time, the box body is equipped with doors that can be opened and closed at the positions corresponding to the dust filter area and dust collection area, which are used for maintenance and cleaning of the dust filter area and dust collection area. The gas demisting area is connected to the box body. Used to discharge filtered air.

[0035]In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific embodiments.

[0036] First of all, "one embodiment" or "embodiment" referred to herein refers to a specific feature, structure or ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com