Built-in ultrasonic electrode body structure and ultrasonic battery thereof

An ultrasonic and electrode body technology, which is applied in the direction of secondary batteries, lead-acid batteries, lead-acid battery electrodes, etc., can solve the problems of reducing the structure of ultrasonic batteries, low charging and discharging efficiency, and failure to work normally, so as to improve charging and discharging efficiency, The effect of high safety and rapid electronic movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

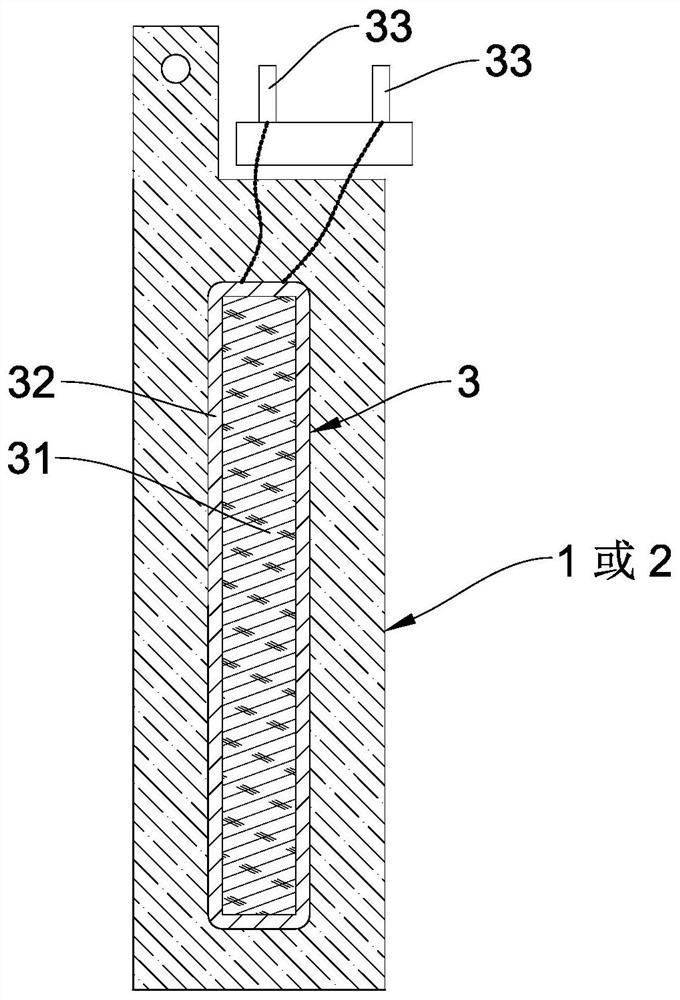

[0019] Such as figure 1 As shown, a built-in ultrasonic electrode body structure described in the present invention includes a positive electrode body 1 or a negative electrode body 2. In order to achieve the purpose proposed by the present invention, it includes an ultrasonic vibration module 3 built in the positive electrode body 1 or negative electrode body 2. . The built-in refers to installing or processing on the positive electrode body 1 and the negative electrode body 2, and pre-installing them; this depends on the raw materials used in the production of the positive electrode body 1 and the negative electrode body 2. For example, for similar metal materials, an inner cavity space can be reserved for later installation therein; for similar non-metallic materials, the ultrasonic vibration module 3 can be pre-placed in it during processing and integrally formed. The ultrasonic vibration module 3 includes an ultrasonic vibration element 31 and an insulating material laye...

Embodiment 2

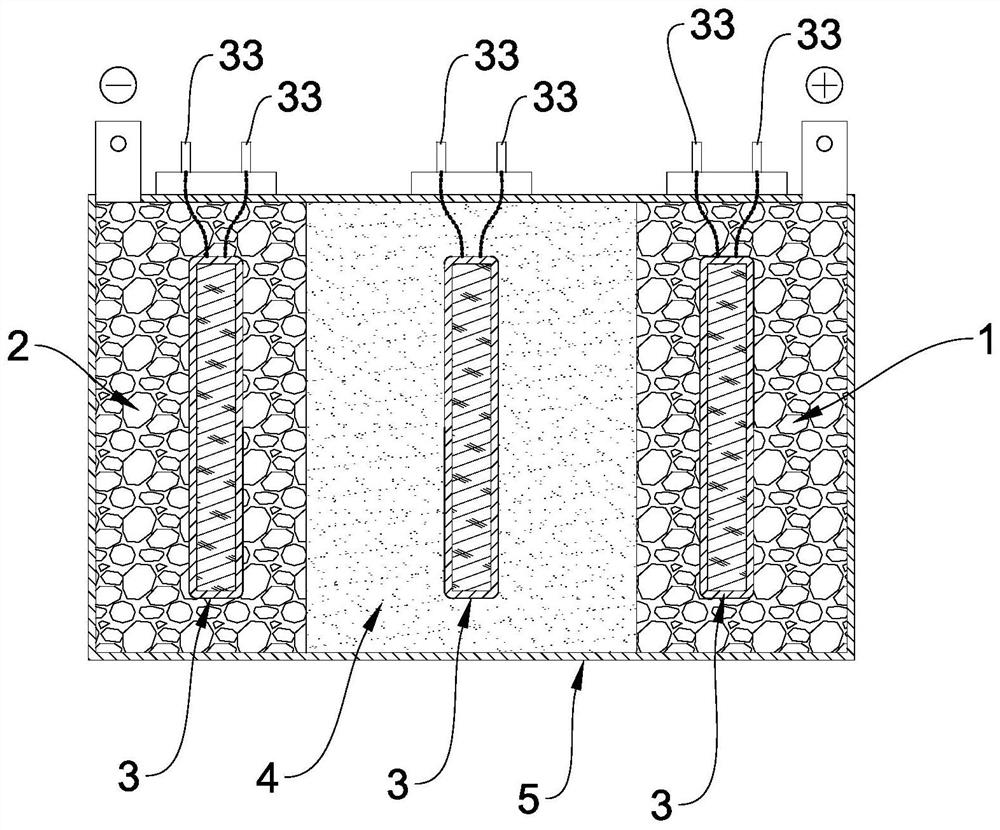

[0021] The second embodiment is an embodiment of an ultrasonic solid-state lithium battery constructed by applying the built-in ultrasonic electrode body structure of the first embodiment to a solid-state lithium battery. Such as figure 2 As shown, the ultrasonic solid-state lithium battery includes a positive electrode body 1, a negative electrode body 2, a solid electrolyte 4, a battery casing 5, etc., and also includes an ultrasonic vibration module 3 built in the positive electrode body 1 and the negative electrode body 2 respectively. The vibration module 3 includes an ultrasonic vibration element 31 and an insulating material layer 32 coated on the surface of the ultrasonic vibration element 31. On or outside the top of the positive electrode body 1 and the negative electrode body 2, there are also electrical contacts with the ultrasonic vibration element 31, respectively. Connect terminal 33. In order to further improve the energy efficiency of the ultrasonic vibratio...

Embodiment 3

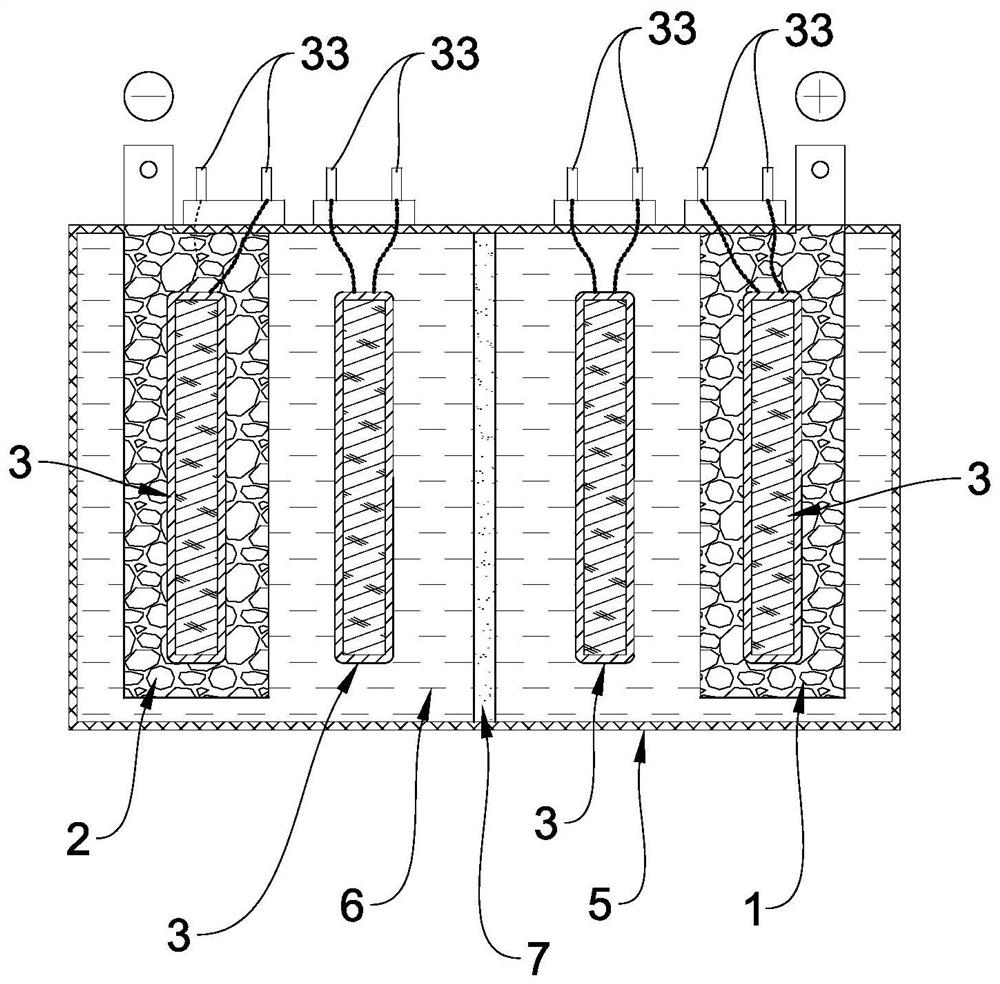

[0023] The third embodiment is an embodiment of an ultrasonic lithium battery constructed by applying the built-in ultrasonic electrode body structure of the first embodiment to an ordinary lithium battery. Such as Figure 4 As shown, the ultrasonic lithium battery includes a positive electrode body 1, a negative electrode body 2, an electrolyte 6, a battery case 5, a separator 7, and an ultrasonic vibration module 3 built in the positive electrode body 1 and the negative electrode body 2 respectively. The ultrasonic vibration module 3 includes an ultrasonic vibration element 31 and an insulating material layer 32 coated on the surrounding surface of the ultrasonic vibration element 31. On or outside the top of the positive electrode body 1 and the negative electrode body 2, there are respectively provided with the ultrasonic vibration element 31. The terminal 33 for electrical connection. In order to further improve the energy efficiency of the ultrasonic vibration module 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com