A steel wire rope automatic guide equipment for steel wire rope conveyor belt production line

An automatic guidance and wire rope technology, applied in the field of wire rope guidance, can solve the problems of affecting the overall progress of wire rope production, stagnation of processing procedures, time-consuming and labor-intensive problems, and achieve the effect of reducing labor input, ensuring normal operation and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

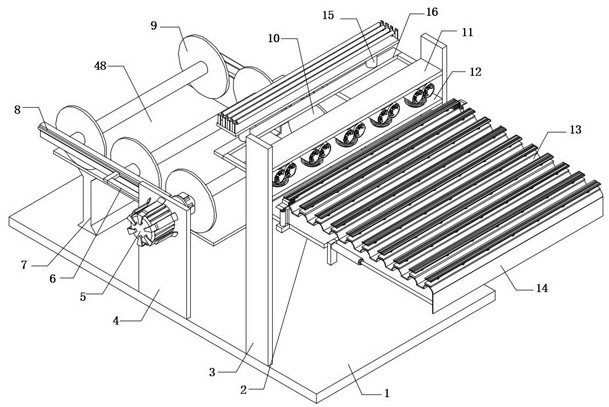

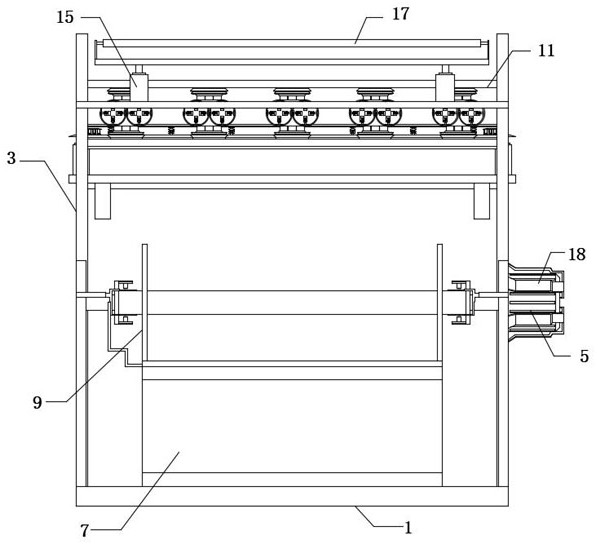

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

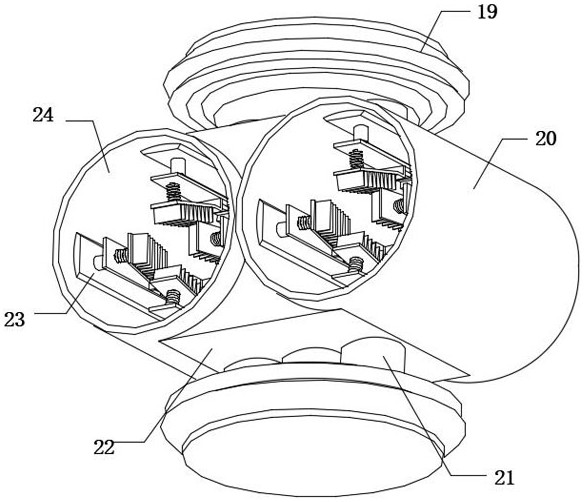

[0031] Refer Figure 1-4A wire rope conveyor belt production line wire rope automatic guidance device, including a table 1, and the top outer wall of the table 1 has two support plates 3, and the opposite side of the two support plates 3 fixes the upper layer plate 11 and The lower layer plate 12, the upper layer plate 11 and the lower outer wall of the lower plate 12 are equally connected to the electromagnet 19, and the two electromagnets 19 located on the upper layer plate 11 and the lower plate 12 are placed in one tube. The outer wall of the 20 and the second guide 24, the No. 1 guide tube 20, and the second guide tube 24 are fixed to two connecting frames 22, and the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com