Method for controlling electric arc furnace steelmaking end point

A technology of steelmaking end point and control method, which is applied in the field of electric arc furnace steelmaking, can solve the problems of reducing the production efficiency of the electric arc furnace steelmaking process, increasing production costs, and slowing down the pace of smelting, so as to avoid the danger of manual temperature measurement and sampling, Improve the hit rate and speed up the effect of smelting rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

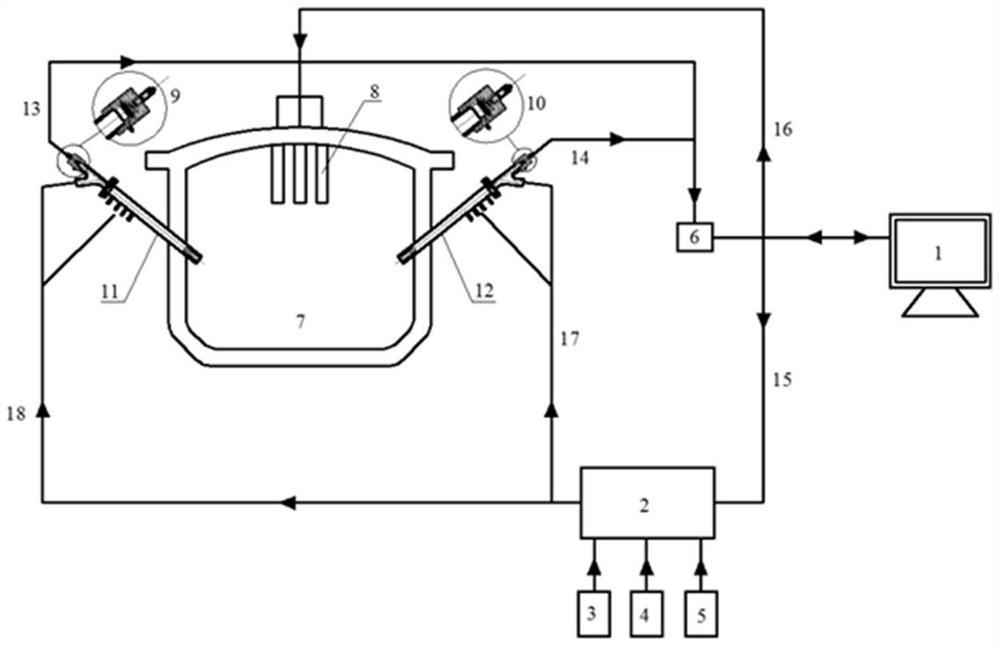

[0042] The invention is applied in 100-ton electric arc furnace steelmaking. The oxygen lance on the electric arc furnace wall is installed at an angle of 60° to the horizontal plane. It is smelted with a 50% molten iron ratio. The Mach number of the nozzle is 2, the gas flow rate is 2500m3 / h, and the pressure is 0.8MPa. Requirements for tapping at the end of smelting: temperature: 1650°C-1670°C, carbon content: 0.09%-0.11%. The smelting process adopts the electric arc furnace steelmaking end point control mode of smelting end point measurement of molten steel temperature and carbon content and switching of oxygen blowing power supply smelting cycle, which specifically includes the following contents:

[0043] Step 1: 30 minutes after the start of smelting, under the action of the computer control system, the system switches to the smelting end point measurement mode: the gas supply valve group completes the N2 / O2 switching, and the oxygen supply of the 4 electric arc furnace w...

Embodiment 2

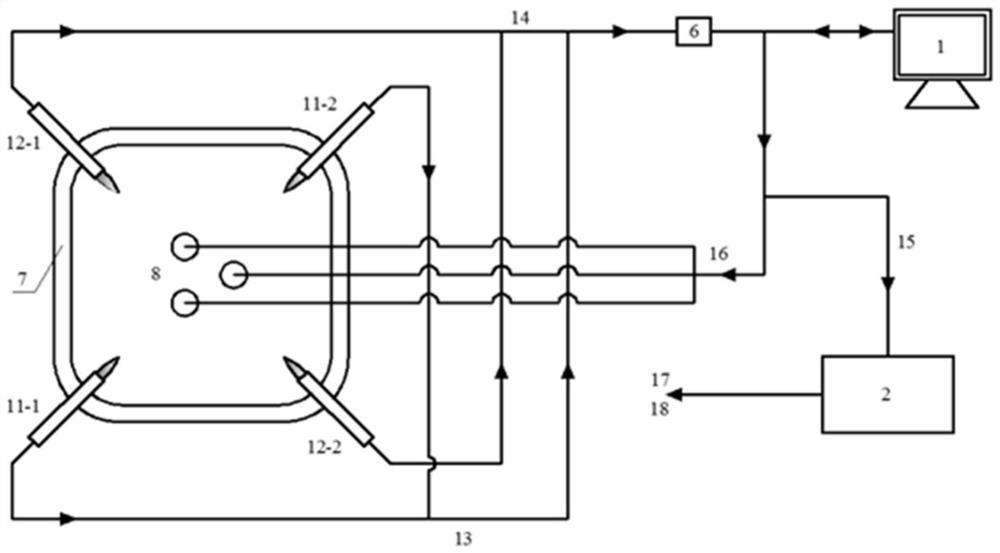

[0051]The present invention is applied in 150-ton electric arc furnace steelmaking. The oxygen lance on the electric arc furnace wall is installed at an angle of 60° to the horizontal plane. It is smelted with a 60% molten iron ratio. The Mach number of the nozzle is 2, the gas flow rate is 3000m3 / h, and the pressure is 0.8MPa. Requirements for tapping at the end of smelting: temperature: 1650°C-1670°C, carbon content: 0.13%-0.15%. The smelting process adopts the control mode of electric arc furnace steelmaking end-point control mode in which the carbon content of molten steel at the end of smelting is measured at fixed points, the temperature of molten steel is continuously measured, and the smelting with oxygen blowing and power supply is carried out simultaneously, which specifically includes the following:

[0052] Step 1: 35 minutes after the start of smelting, under the action of the computer control system, the system switches to the smelting end point measurement mode: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com