Lateral movement transferring and conveying system in automatic three-dimensional warehouse provided with functional area

A technology of functional area and three-dimensional warehouse, which is applied in the field of transportation system, can solve the problems of high input cost and maintenance cost, high requirements for ground flatness, and high cost of construction, and achieve the effect of simple structure, low cost, and fast transfer and docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the accompanying drawings and preferred embodiments.

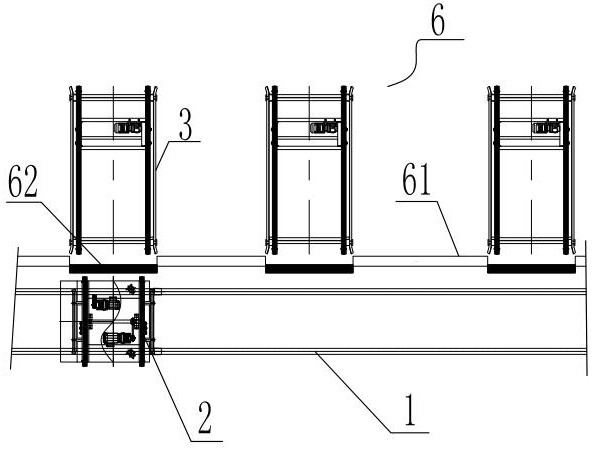

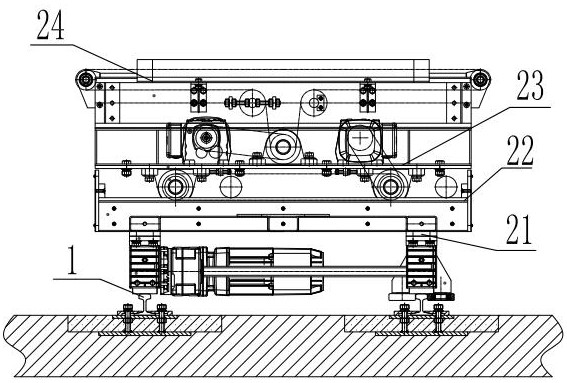

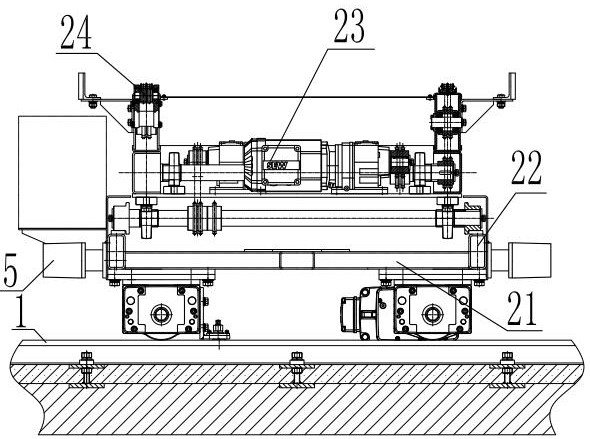

[0020] like figure 1 , figure 2 , image 3 As shown, there is a side-shifting and transporting system in an automated three-dimensional warehouse with functional areas. The partition wall 61 of the functional area 6 is provided with a number of cargo entrances and exits, and a fire door 62 is installed on each entrance and exit. Each conveying line inside the functional area 6 has a corresponding connection and transfer end 3, and the conveying surfaces of each connection and transfer end 3 for conveying goods are at the same height. On state. A pair of walking guide rails 1 are fixed on the ground of the automated three-dimensional warehouse outside the functional area. The pair of walking guide rails 1 pass through each cargo entrance and exit of the functional area. At least one side-moving rail shuttle 2 is movably supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com