Mold conveying platform

A platform and mold technology, which is applied in the field of heavy object transportation devices, can solve the problems of noise, high mold temperature, and the process of affecting the use of molds, etc., and achieve the effects of small commutation impact, high transportation efficiency, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

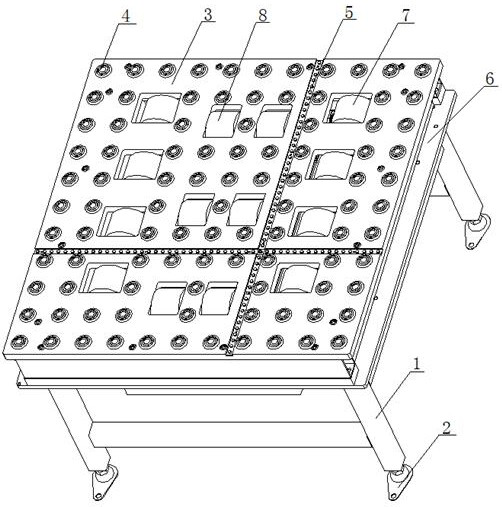

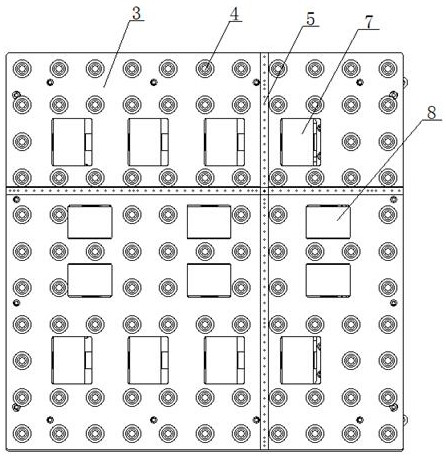

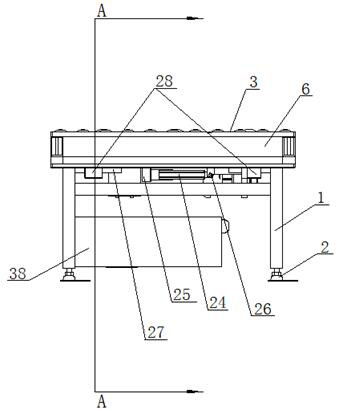

[0032] see Figure 1 to Figure 15 , a mold transport platform, including bracket 1, pulley II 21, transverse drive motor 13, longitudinal drive motor 20, jack 24, slide bar 27, pulley V 37 and control box 38.

[0033] see Figure 1 to Figure 15 , the upper part of the support 1 is provided with a base plate 33, and the base plate 33 is surrounded by a frame surrounded by support plates 6, and a horizontal roller bracket 39 and a longitudinal roller bracket are arranged above the inner bottom plate 33 of the frame surrounded by the support plates 6. 40. The two ends of the horizontal roller bracket 39 are correspondingly provided with two sets of eccentric hole pair holes 41, and the two ends of the longitudinal roller bracket 40 are correspondingly provided with two sets of eccentric shaft pair holes 42. The frame middle part that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com