High-frequency induction welding device for steel pipe

A technology for high-frequency induction welding and steel pipes, which is applied to high-frequency current welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of steel pipe size changes, material waste, and easy changes in the roundness of steel pipes, etc., to prevent deformation and prevent The effect of sudden cold contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

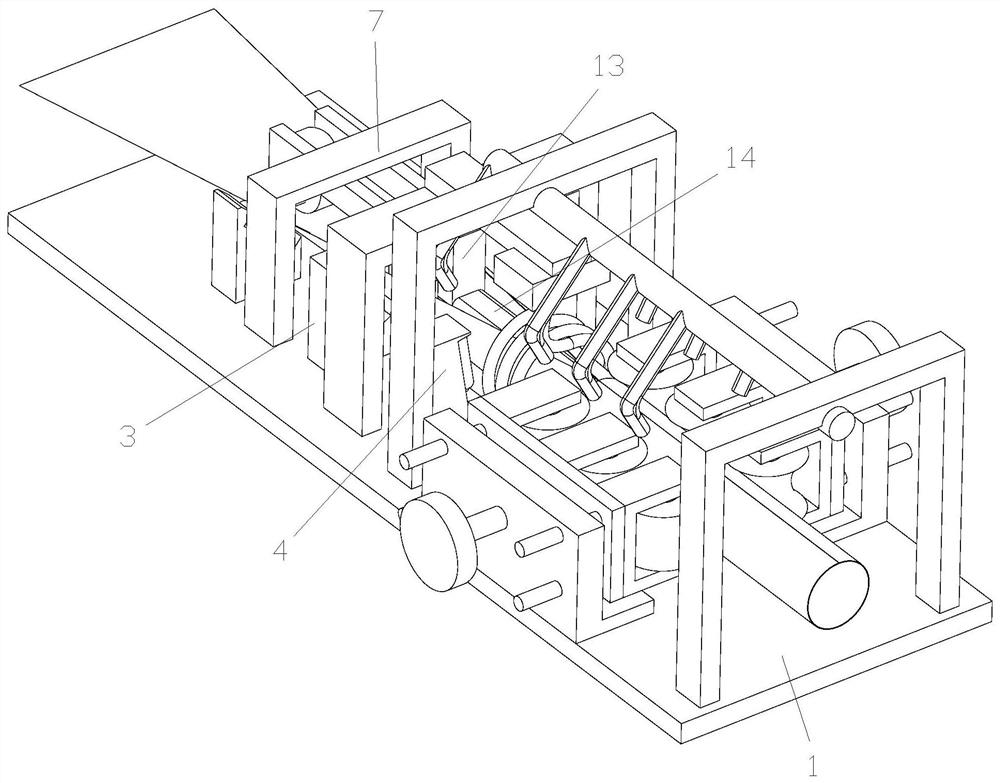

[0015] Embodiment: a steel pipe high-frequency induction welding device, such as Figure 1-Figure 2 As shown, it includes an installation bottom plate 1, the middle position of the upper surface of the installation bottom plate 1 is provided with a first guide roller group 2, a second guide roller group 3 and a third guide roller group 4 in turn, and the first guide roller group 2 It includes two symmetrically arranged first bases 5, the upper end of the first base 5 is rotatably connected with a guide roller 6, and the guide roller 6 is arranged in an inclined shape. The second guide roller group 3 and the third guide roller The structure of group 4 is consistent with the structure of the first guide roller group 2, and the angles between the guide rollers 6 and the installation bottom plate 1 in the first guide roller group 2 to the third guide roller group 4 increase successively, and the first guide roller group A first installation bracket 7 is arranged on the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com