Turning production equipment for bevel angle threads in non-standard conical fastening part

A technology for fastening parts and production equipment, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of time-consuming and laborious tapping, and achieve the effect of avoiding time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be described in the following examples in the embodiments of the present invention, and it is clear that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained without making creative labor.

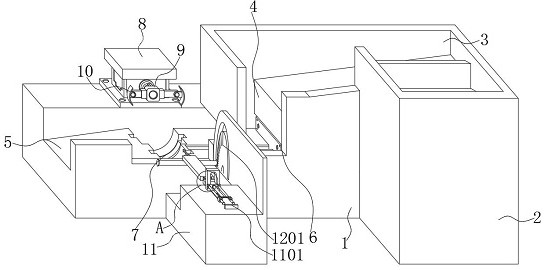

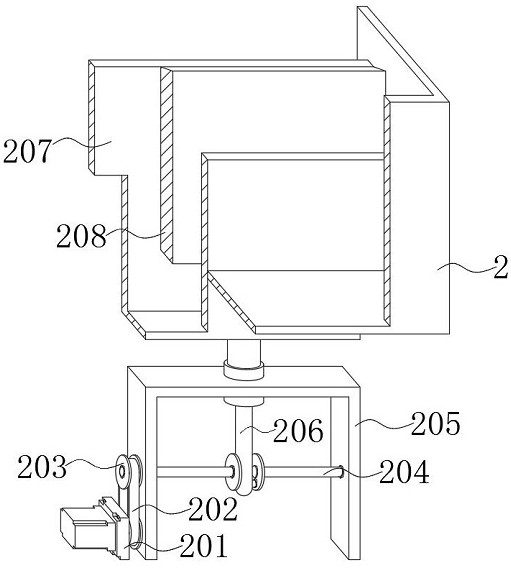

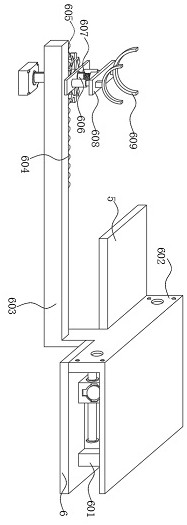

[0029] See Figure 1-6 The present invention provides a technical solution: an internal oblique angle threaded vehicle cutting production apparatus, including a bottom chassis 1, a bottom chassis 1, and a feed device 2, a feed device 2 The left side of the casing and the right side of the bottom chassis 1 are welded and fixed, and the casing bottom bolt of the feed device 2 is fixedly mounted, the drive motor 201, the right side output terminal of the drive motor 201 is engaged. The synchronous bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com