Spraying system for rubber strip surface treatment and implementation method thereof

A technology of surface treatment and rubber strip, applied in the field of rubber strip spraying system, can solve the problems of inability to work for a long time, affecting the effect of spraying, low spraying efficiency, etc., and achieve the effect of improving production spraying efficiency, improving production quality and coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

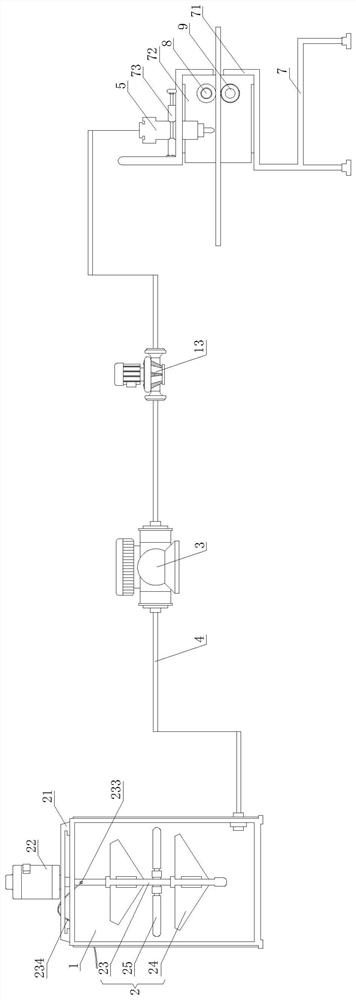

[0033] In order to better demonstrate the implementation process of the spraying system for the surface treatment of rubber strips, this embodiment now proposes an implementation method for the spraying system for the surface treatment of rubber strips, including the following steps:

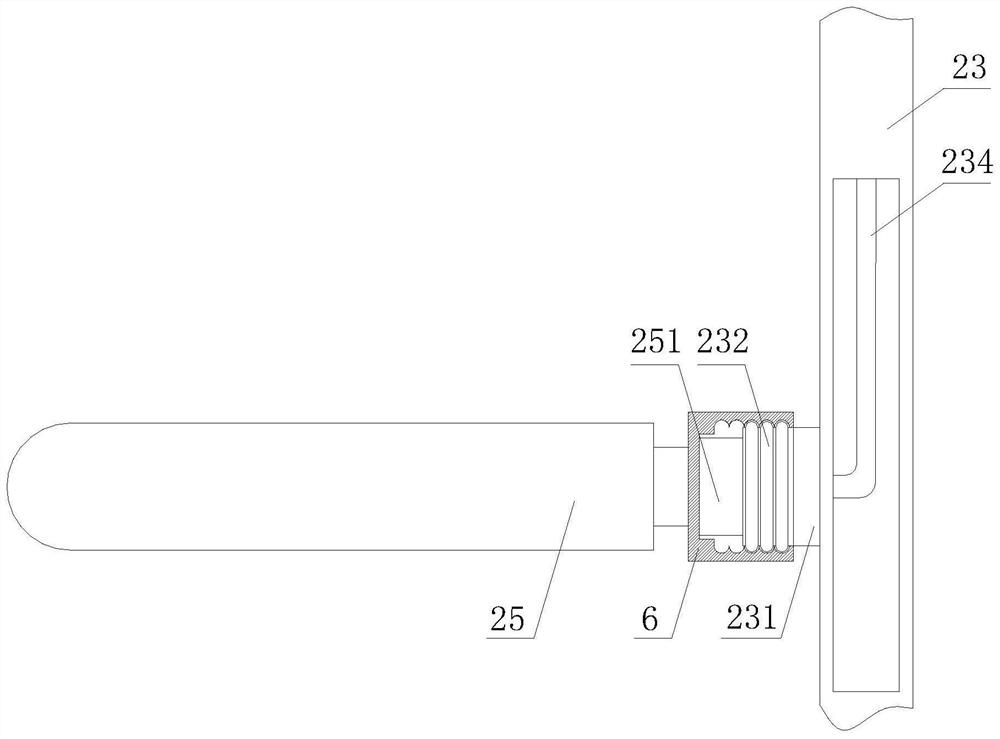

[0034] The first step: After pouring the spraying material into the paint tank 1, start the first motor 22 to drive the stirring blade 24 to rotate to stir the paint, and at the same time connect the power supply of the heating tube 25 to make the heating tube 25 generate heat to heat the paint .

[0035] Step 2: After the paint is evenly stirred, start the peristaltic pump 3 to alternately squeeze and release the delivery hose 4 to pump the paint into the spray gun 5, and in the process of pumping the paint, the balance valve 13 makes the The paint can flow smoothly and evenly in the delivery hose 4 .

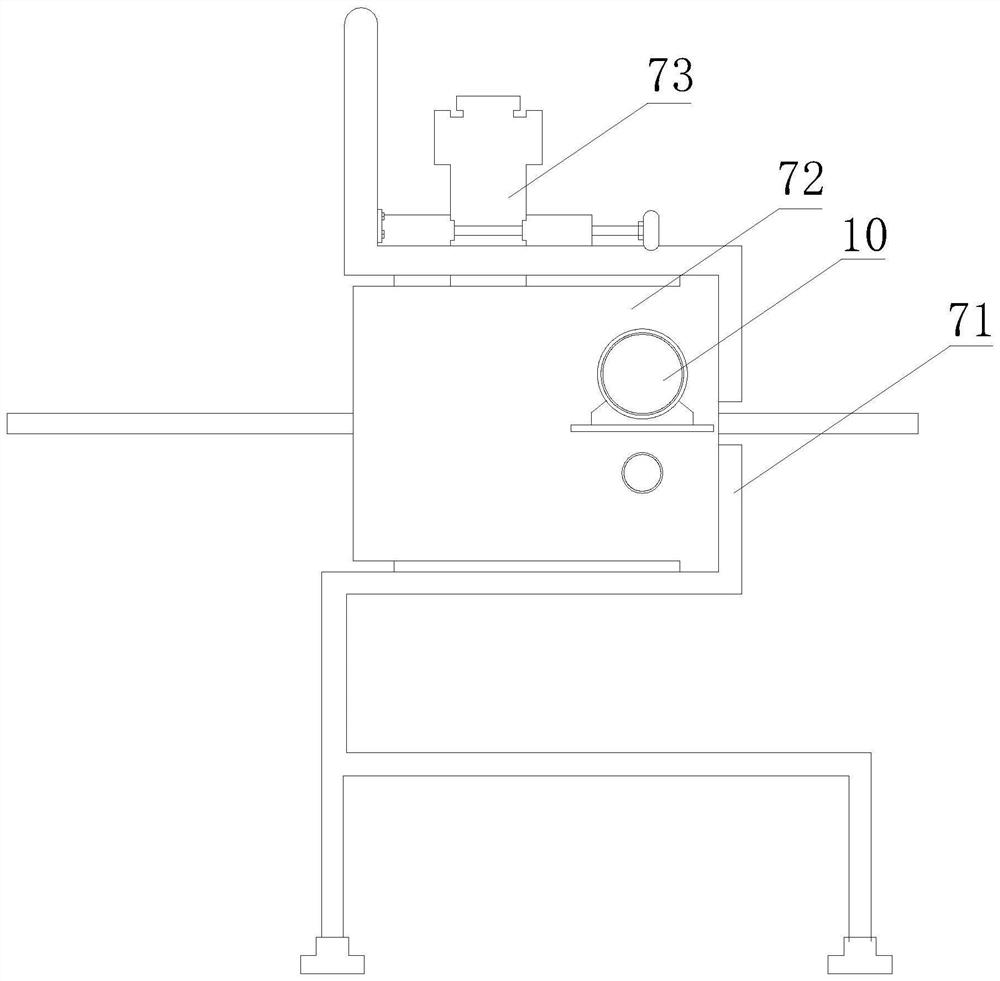

[0036] Step 3: Before pumping paint to the spray gun 5, place the spray gun 5 on the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com