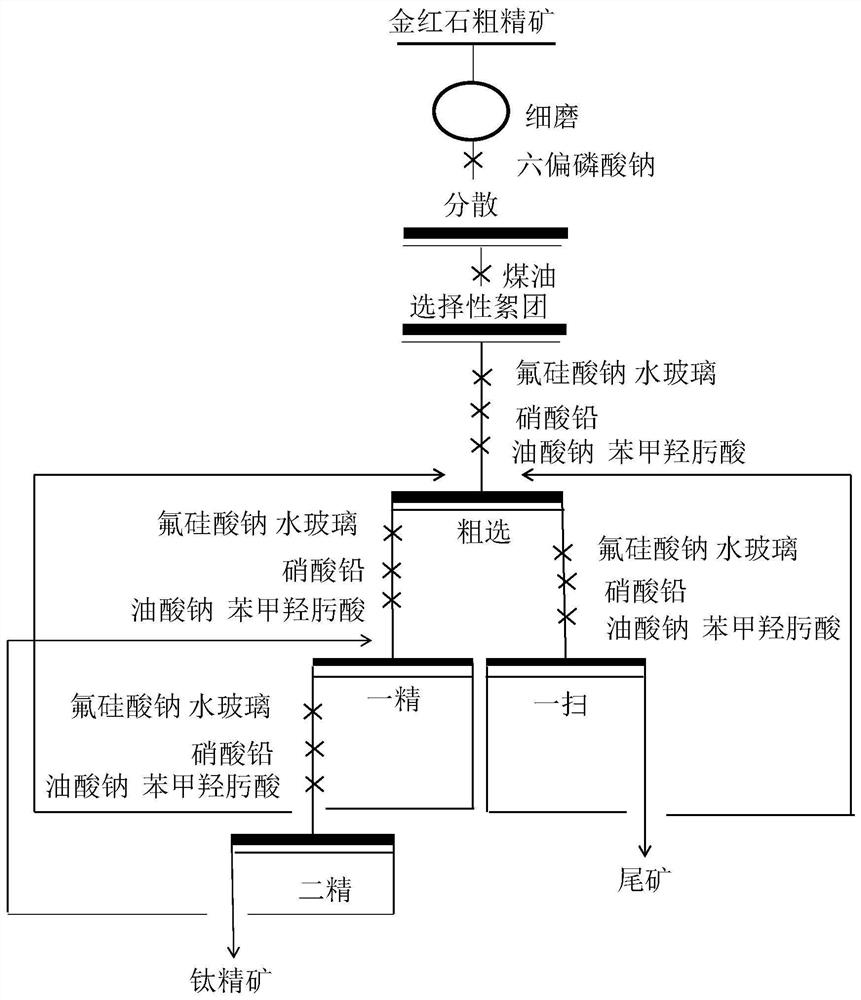

Selective flocculation column flotation concentration process for micro-fine particle rutile ores

A rutile ore and selective technology, applied in the mineral processing field, can solve problems such as the adverse effects of mechanical entrainment, and achieve the effects of improving flotation indicators, improving grades, uniform bubbles and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the rutile rough concentrate used in the present invention, the average titanium grade is 11.86%.

[0031] first step

[0032] Carry out fine grinding operation of coarse ore concentrate, and obtain 92% of the particle size in the fine-grained ore slurry is not higher than 0.074mm.

[0033] Mix the fine material pulp with sodium hexametaphosphate, and fully disperse the particles in the pulp under the conditions of sodium hexametaphosphate dosage 500g / t, stirring time 9min, stirring speed 1000r / min.

[0034] The dispersed pulp is mixed with kerosene, and the particles in the pulp are fully and selectively agglomerated under the conditions of 1000g / t kerosene dosage, 15min stirring time and 1200r / min stirring speed.

[0035] second step

[0036] The agglomerated ore pulp is mixed with sodium fluorosilicate, water glass, lead nitrate, sodium oleate, and benzyl hydroxamic acid and fed into the flotation column for selective flocculation column flotation and concentrat...

Embodiment 2

[0046] The ore sample that adopts is identical with embodiment 1.

[0047] first step

[0048]Carry out fine grinding operation of coarse ore concentrate, and obtain 92% of the particle size in the fine-grained ore slurry is not higher than 0.074mm.

[0049] Mix the fine material pulp with sodium hexametaphosphate, and fully disperse the particles in the pulp under the conditions of sodium hexametaphosphate dosage 500g / t, stirring time 9min, stirring speed 1000r / min.

[0050] The dispersed pulp is mixed with kerosene, and the particles in the pulp are fully selectively flocculated under the conditions of kerosene dosage of 1000g / t, stirring time of 15min, and stirring speed of 1200r / min.

[0051] second step

[0052] The agglomerated pulp is mixed with sodium fluorosilicate, water glass, lead nitrate, sodium oleate, and benzyl hydroxamic acid to carry out the roughing process of selective flocculation column flotation and concentration of fine-grained rutile ore. In the rou...

Embodiment 3

[0062] The ore sample that adopts is identical with embodiment 1.

[0063] first step

[0064] Carry out fine grinding operation of coarse ore concentrate, and obtain 92% of the particle size in the fine-grained ore slurry is not higher than 0.074mm.

[0065] Mix the fine material pulp with sodium hexametaphosphate, and fully disperse the particles in the pulp under the conditions of sodium hexametaphosphate dosage 600g / t, stirring time 8min, stirring speed 1100r / min.

[0066] The dispersed pulp is mixed with kerosene, and the particles in the pulp are fully and selectively agglomerated under the conditions of 1200g / t kerosene dosage, 12min stirring time and 1200r / min stirring speed.

[0067] second step

[0068] Mix the agglomerated ore pulp with sodium fluorosilicate, water glass, lead nitrate, sodium oleate, and benzyl hydroxamic acid to carry out selective flocculation column flotation and concentration of fine-grained rutile ore. In any process of roughing, first benef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com