Sealed arc extinguishing device capable of bearing high-strength pressure

An arc extinguishing device, high-strength technology, applied in electrical components, spark gaps, spark gap components and other directions, can solve problems such as insufficient air tightness, arc extinguishing device burst, large shock wave pressure, etc., to optimize the interrupting mechanism, interrupting Strong ability and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. However, it is to be noted that many of the details listed in the specification are merely in order to make the reader have a thorough understanding of the present invention, even if there is no such specific details, these aspects of the invention may be implemented.

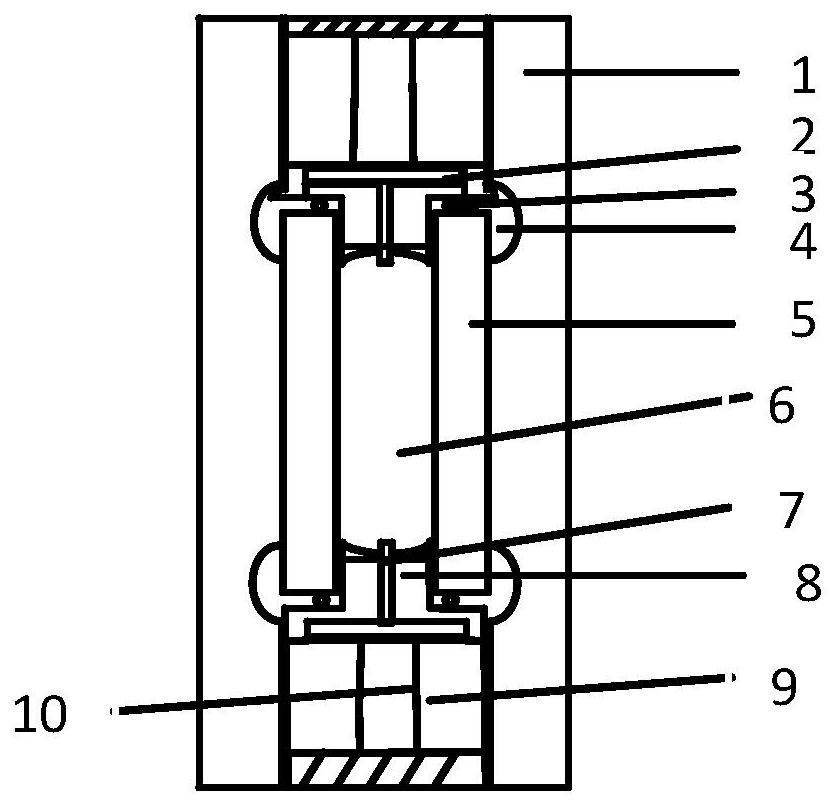

[0025] like figure 1 As shown in a high strength to withstand pressure of the sealing arc extinguishing apparatus, comprising a plastic sleeve in a silicone seal, steel sleeve 4, a ceramic tube 5, 6 interrupter insulating liquid, the conductive electrode 7, the sealing 8 silica gel, 7 nested conducting electrode (8), silicone seal 8 seals provided at both ends of the ceramic tube 5, the sleeve 4 is fastened in a sealed steel silica gel 8 and the outer ceramic tube is connected at the 5, 6 disposed in the arc-ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com