Non-destructive testing method for weld defects based on computer vision

A computer vision and non-destructive testing technology, applied in the field of computer vision, can solve the problems of misjudgment and danger of weld hazards, and achieve the effect of high degree of automation and accurate recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

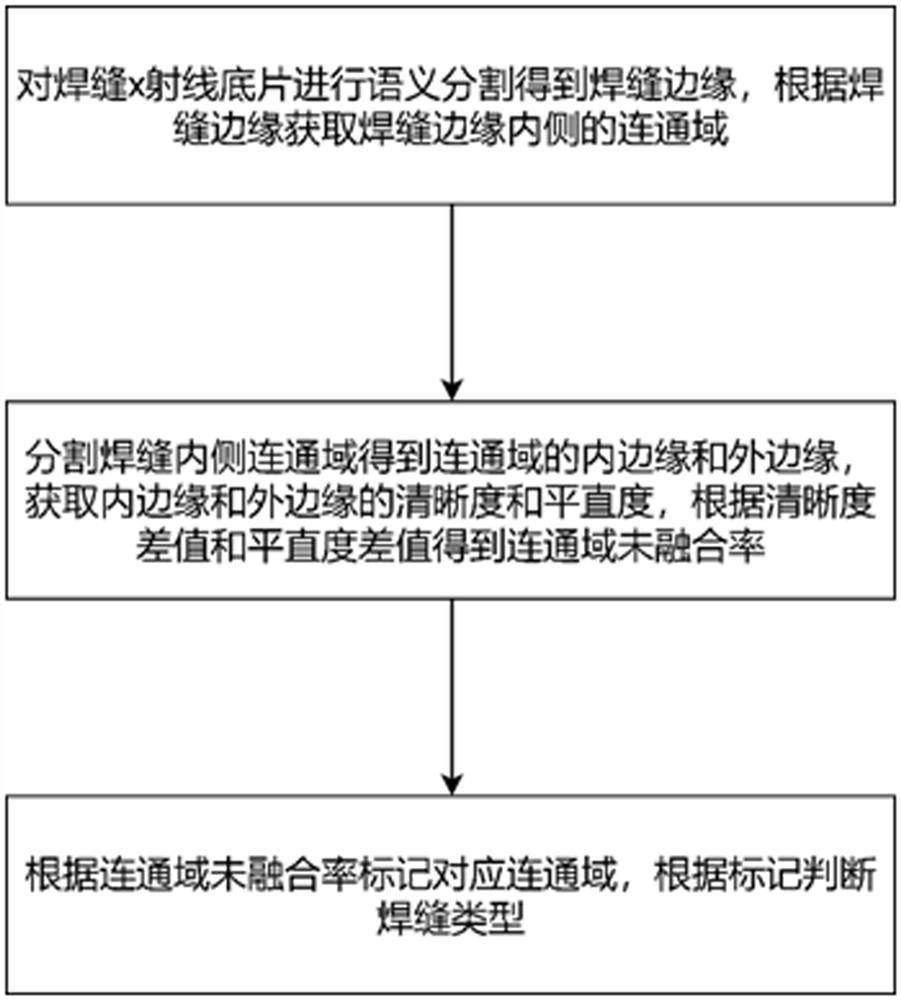

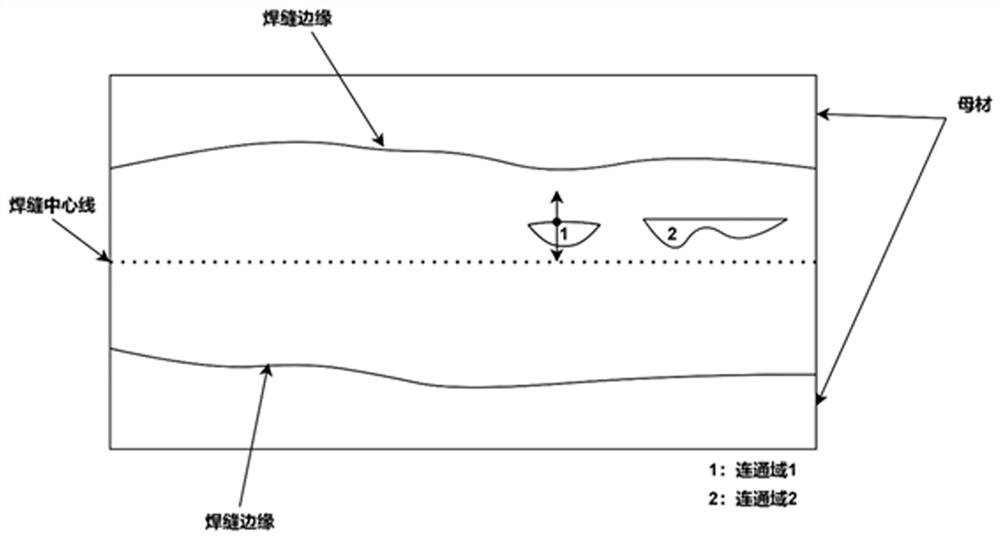

[0042] Such as figure 1 As shown, this embodiment provides a method for non-destructive detection of weld defects based on computer vision, including the following:

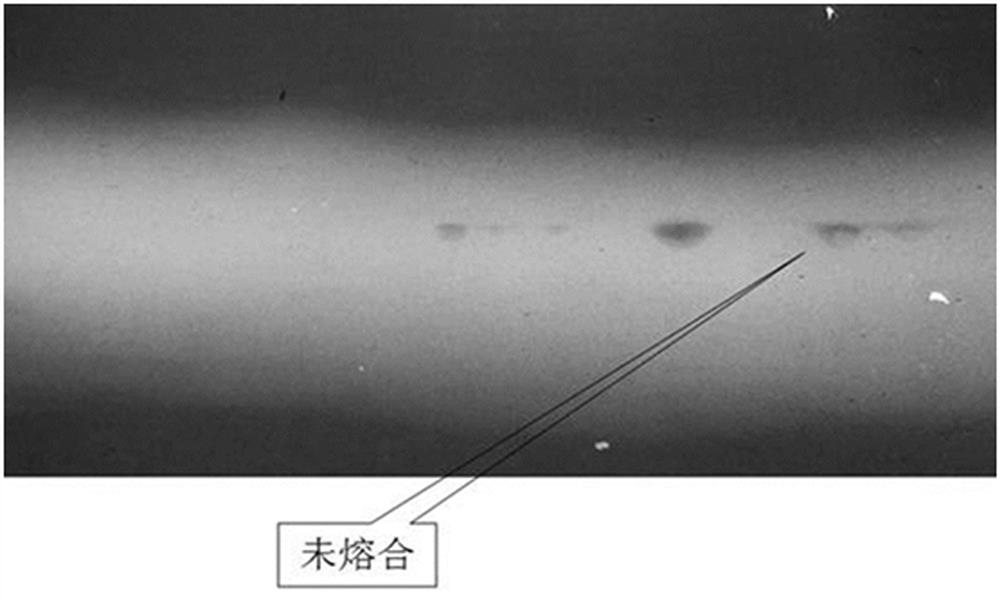

[0043] Semantic segmentation is performed on the X-ray film of the weld to obtain the edge of the weld, and the connected domain inside the edge of the weld is obtained according to the edge of the weld.

[0044] Welding defects refer to defects formed during the welding process at the welded joint. Welding defects include porosity, slag inclusions, incomplete penetration, incomplete fusion, cracks, pits, undercuts, welding tumors, etc. The pores and slag inclusions (points) in these defects are volume defects. Slag, incomplete penetration, incomplete fusion and cracks are linear defects, which can also be called surface defects. In particular, cracks and lack of fusion are surface defects. Pits, undercuts, weld bumps and surface cracks are surface defects. Other defects (including internal buried cracks) ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com