A network optical fiber defect detection device and method

A technology of defect detection and optical fiber, which is applied in the direction of measuring devices, optical instrument testing, testing optical fiber/optical waveguide equipment, etc., can solve the problems of poor adjustable effect, insufficient tension of optical fiber lines, and optical fiber loss, etc. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

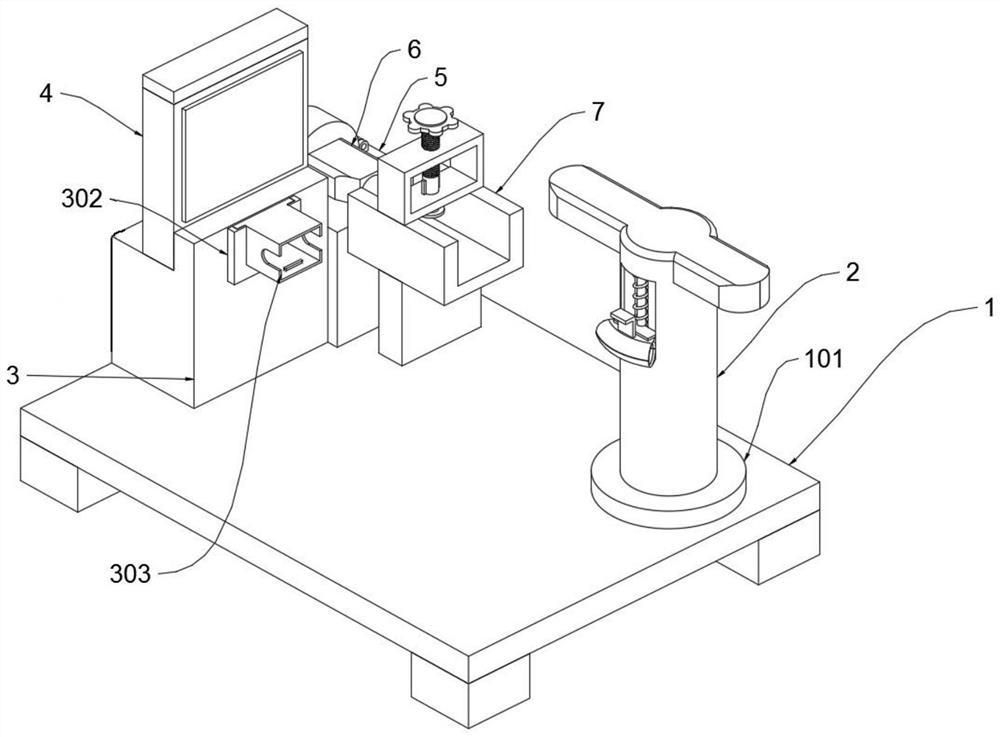

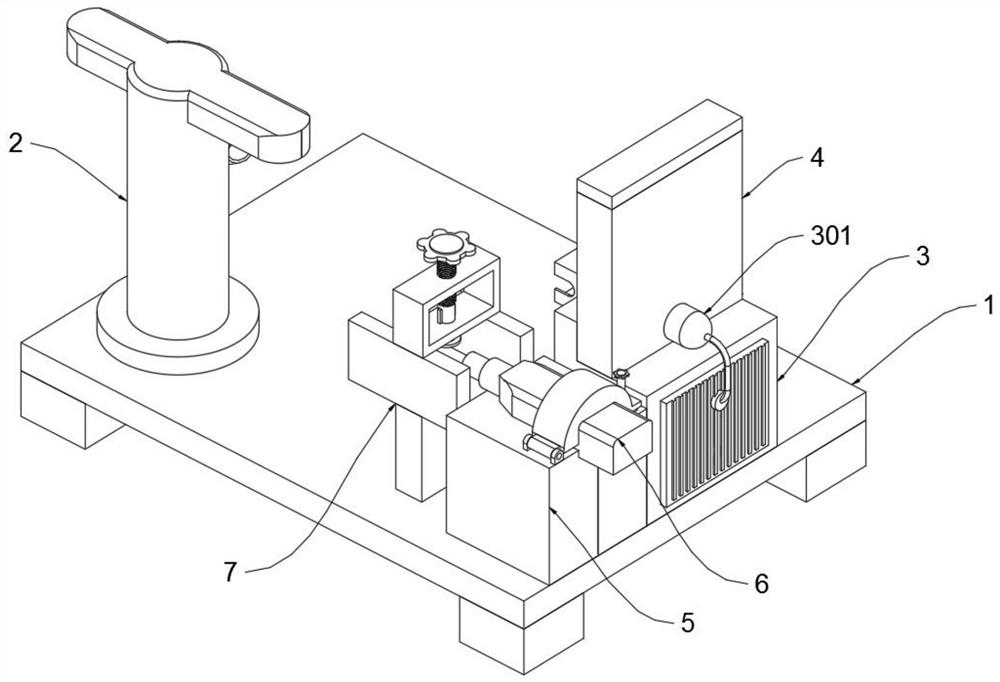

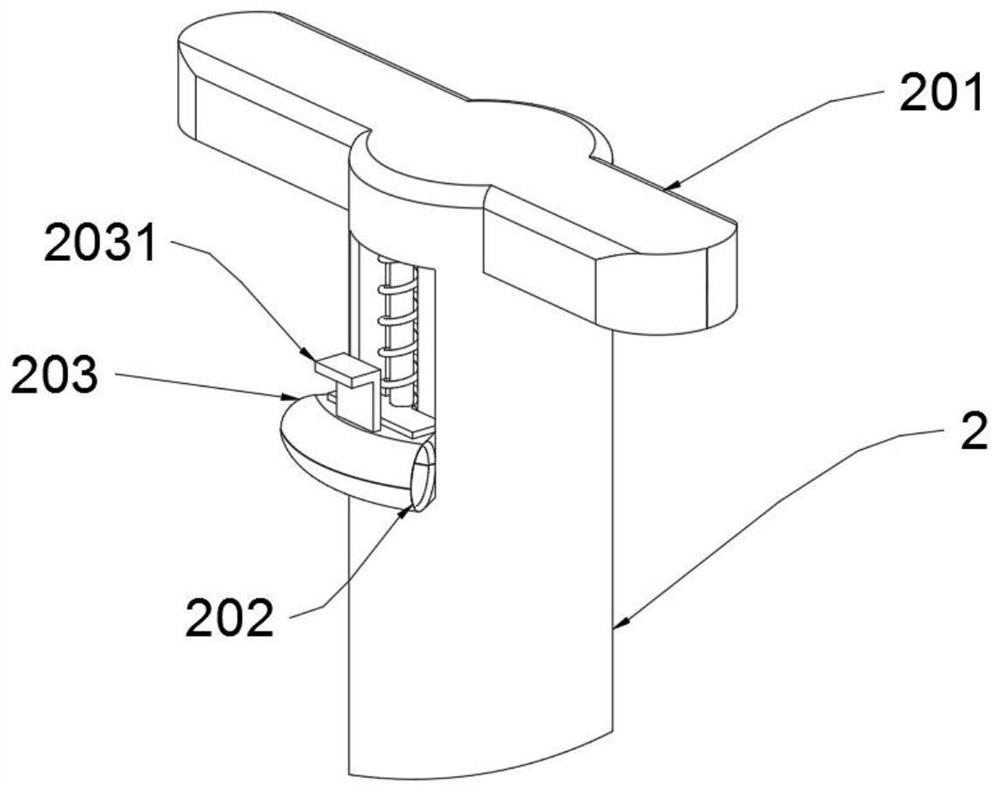

[0043] as attached figure 1 To attach Figure 9 Shown:

[0044] The invention provides a network optical fiber defect detection device and method, comprising a base frame 1, a controller is provided on one side of the base frame 1, the controller electrically controls each electrical component, and a rotating seat 101 is provided on the top of the base frame 1, The top of the seat 101 is provided with a wire column 2, the left end of the base frame 1 is provided with a device main body 3, and the left end of the base frame 1 is slidably connected to an installation device 5, and an optical fiber cleaning pen 6 is provided on the installation device 5;

[0045] The main body 3 of the device is provided with an installation tank 302, and the inside of the installation tank 302 is provided with a plug joint 303, and the top of the main body 3 of the device is connected with a display 4;

[0046] The front end of the mounting device 5 is provided with a fixing device 7 .

[004...

no. 2 example

[0062]Based on the network optical fiber defect detection device and method provided in the first embodiment, the depth of the optical fiber connector plugged into the plug connector 303 needs to be manually regulated in actual use, so it is inevitable that the optical fiber connector will be squeezed and damaged due to excessive force , or too little force leads to inaccurate detection. At the same time, when the wire post 2 is rotated to tighten the optical fiber, the degree of tension cannot be precisely controlled, so not only will it cause damage to the optical fiber, but it will also damage the optical fiber connector Cleanliness detection results are affected; at the same time, when the optical connector is cleaned, the optical fiber cleaning pen 6 is driven by the installation device 5 to move to the end of the optical fiber connector to clean it, so the fixed position of the optical fiber connector in the fixing device 7 and The traveling distance of the optical fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com