Bus station personnel heatstroke prevention device based on thermosensitive principle

A bus station, heat-sensitive technology, applied in the field of sensitive components and sensor manufacturing, can solve the problems of reducing platform temperature, water loss, reducing the practicality of bus platforms, etc., to achieve the goal of improving comfort, improving practicability, and improving humanized services Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

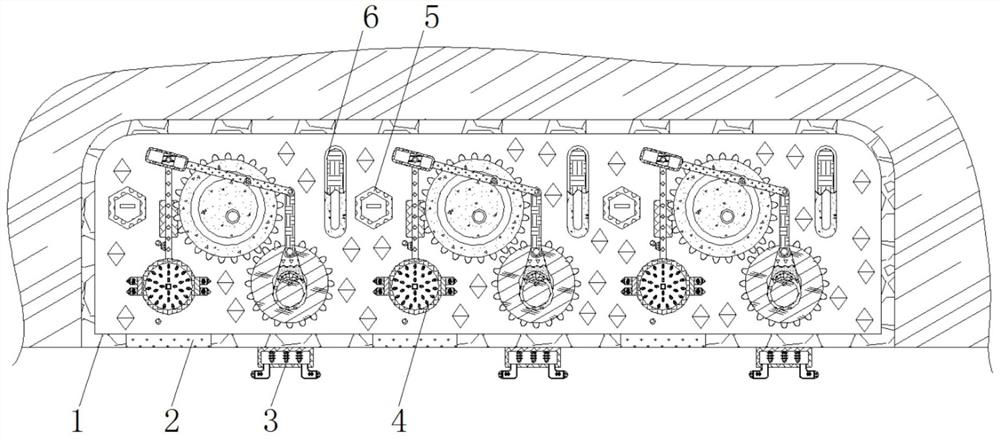

[0028] Please refer to Figure 2-5, a heat stroke prevention device for bus station personnel based on the principle of heat sensitivity, including a casing 1, an outlet 2 is opened on the surface of the casing 1, and a heat-sensitive component 3 is fixedly connected to the outside of the casing 1, and the heat-sensitive component 3 It includes a closed cover 301, a ventilation pipe 302, a flow port 303, and a thermistor 304. The outer casing 1 is fixedly connected with a closed cover 301, and the outside of the closed cover 301 is fixedly connected with a ventilation pipe 302. The surface of the ventilation pipe 302 is provided with a flow port 303, the inside of the closed cover 301 is fixedly connected with a thermistor 304, the number of ventilation pipes 302 is two, and the two ventilation pipes 302 are symmetrically distributed outside the closed cover 301, the positions of the ventilation pipes 302 and the closed cover 301 are corresponding and The specifications match, t...

Embodiment 2

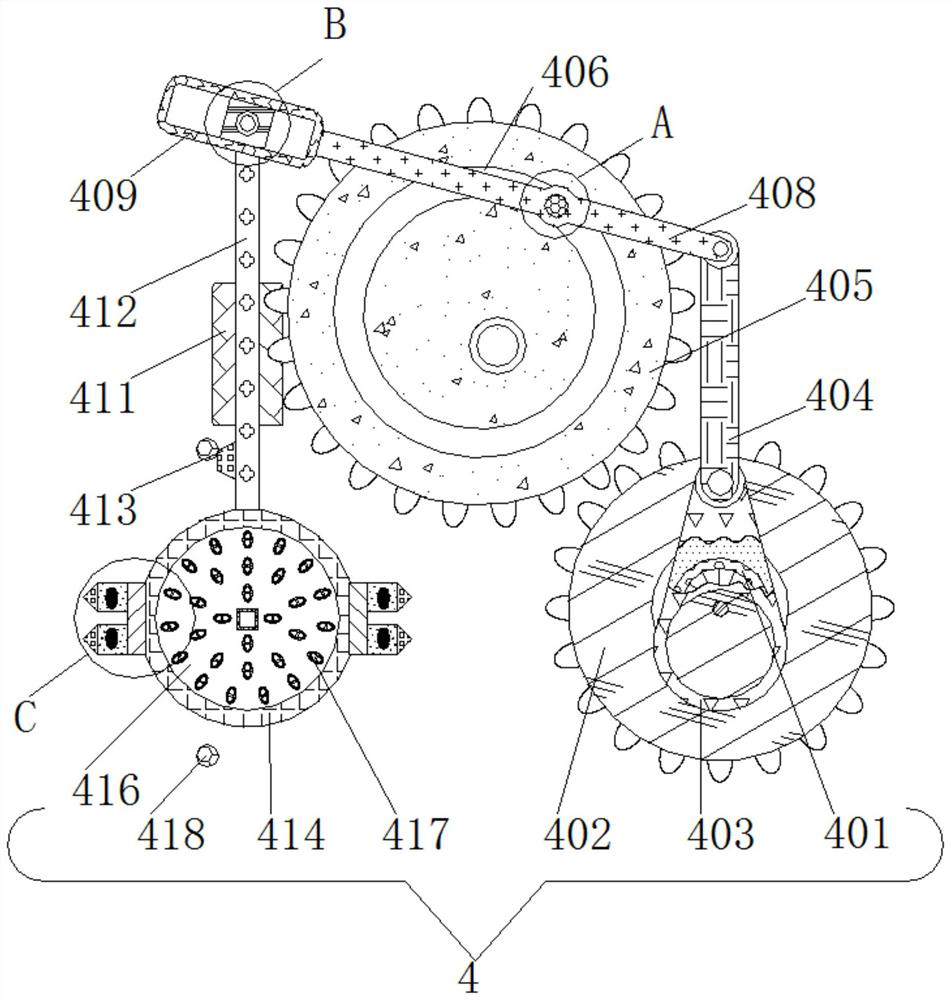

[0030]Please refer to Fig. 6, a heat stroke prevention device for bus station personnel based on the principle of heat sensitivity, comprising a casing 1, the surface of the casing 1 is provided with an outlet 2, and the outside of the casing 1 is fixedly connected with a heat-sensitive component 3 that senses the effect of external high temperature weather, The inner movable connection of shell 1 is with cooling mechanism 4, and cooling mechanism 4 comprises motor 401, runner one 402, connecting rod one 403, connecting rod two 404, runner two 405, chute 406, roller 407, connecting rod three 408, Slide bar 409, moving block 410, slide rail 411, slide plate 412, detection rod 413, support plate 414, electromagnetic pump 415, atomizing plate 416, spray hole 417, contact point 418, the exterior of shell 1 is fixedly connected with motor 401, The outside of the motor 401 is fixedly connected with a runner one 402, the outside of the runner one 402 is movably connected with a connec...

Embodiment 3

[0032] Please refer to Figures 1-6, a heat stroke prevention device for bus station personnel based on the principle of heat sensitivity, which includes a casing 1, an outlet 2 is opened on the surface of the casing 1, and a heat-sensitive component 3 is fixedly connected to the outside of the casing 1, and the heat-sensitive component 3 It includes a closed cover 301, a ventilation pipe 302, a flow port 303, and a thermistor 304. The outer casing 1 is fixedly connected with a closed cover 301, and the outside of the closed cover 301 is fixedly connected with a ventilation pipe 302. The surface of the ventilation pipe 302 is provided with a flow port 303, the inside of the closed cover 301 is fixedly connected with a thermistor 304, the number of ventilation pipes 302 is two, and the two ventilation pipes 302 are symmetrically distributed outside the closed cover 301, the positions of the ventilation pipes 302 and the closed cover 301 are corresponding and The specifications ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com