Crepe paper manufacturing system and manufacturing method based on speed difference wrinkling

A manufacturing system, crepe paper technology, applied in the field of papermaking, can solve the problems of paper web breakage, scraper residual paper scraps, paper web defects, etc., to increase softness, avoid heat loss, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

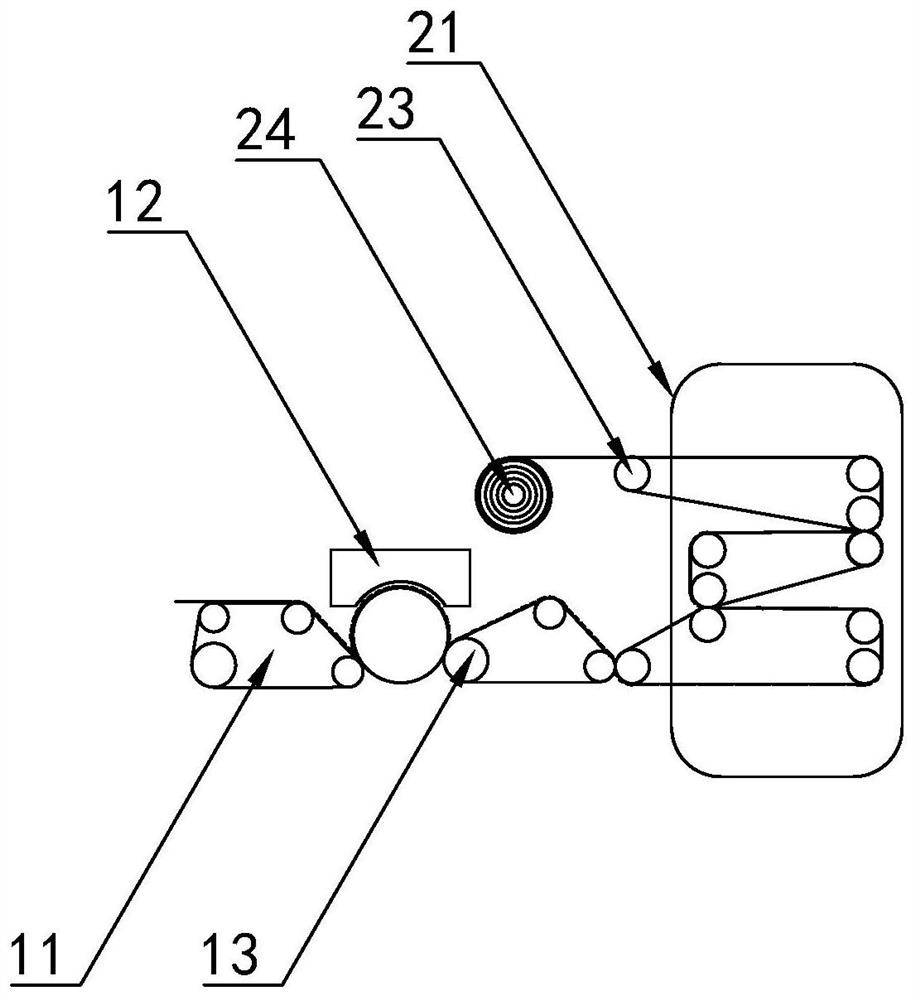

[0086] like Figure 1-Figure 6 As shown, the present invention discloses a crepe paper manufacturing system based on speed difference creping. In a specific embodiment of the present invention, it includes a creping device with a frame;

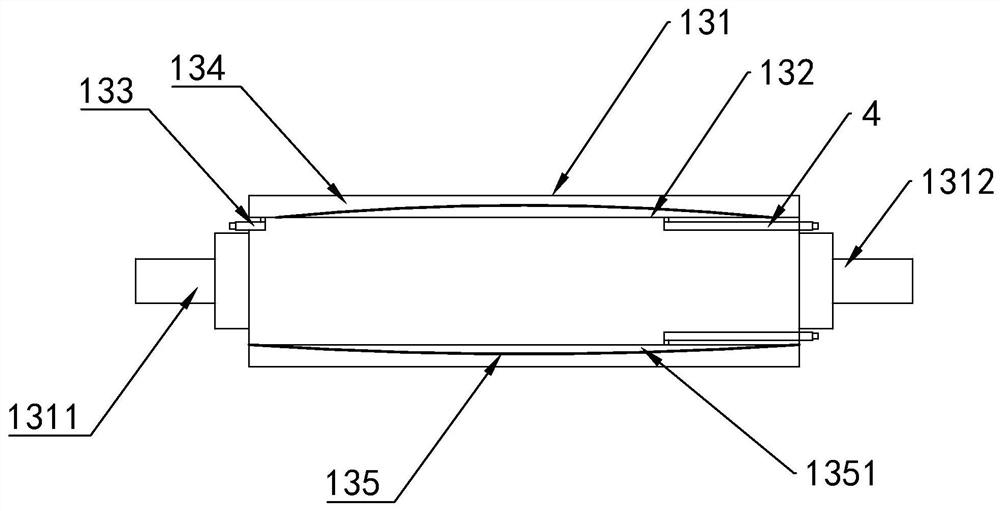

[0087] The creping device includes a paper web input mechanism 11, a drying cylinder 12 and a vacuum creping roller 13; the paper web input mechanism 11, the drying cylinder 12 and the vacuum creping roller 13 are installed on the frame in sequence;

[0088]The vacuum creping roller 13 and the drying cylinder 12 squeeze each other, and the rotation speed of the vacuum creping roller 13 is lower than the rotation speed of the drying cylinder 12 to generate a speed difference. During the process of wrinkling, the dryer will heat the wet paper sheet, and in the process of heating and squeezing, the effect of hot ironing and ironing will be formed, so that the paper can directly reach one step. The effect of forming, the wrinkling effect of this...

Embodiment 2

[0114] In a specific embodiment of the present invention, a method for forming paper is included, and the method for forming paper includes the following steps:

[0115] A1 Preparing wet paper web: The pre-prepared pulp is formed into a wet paper web by a forming machine;

[0116] A2 conveying: convey the formed wet paper web to the dryer for dehydration;

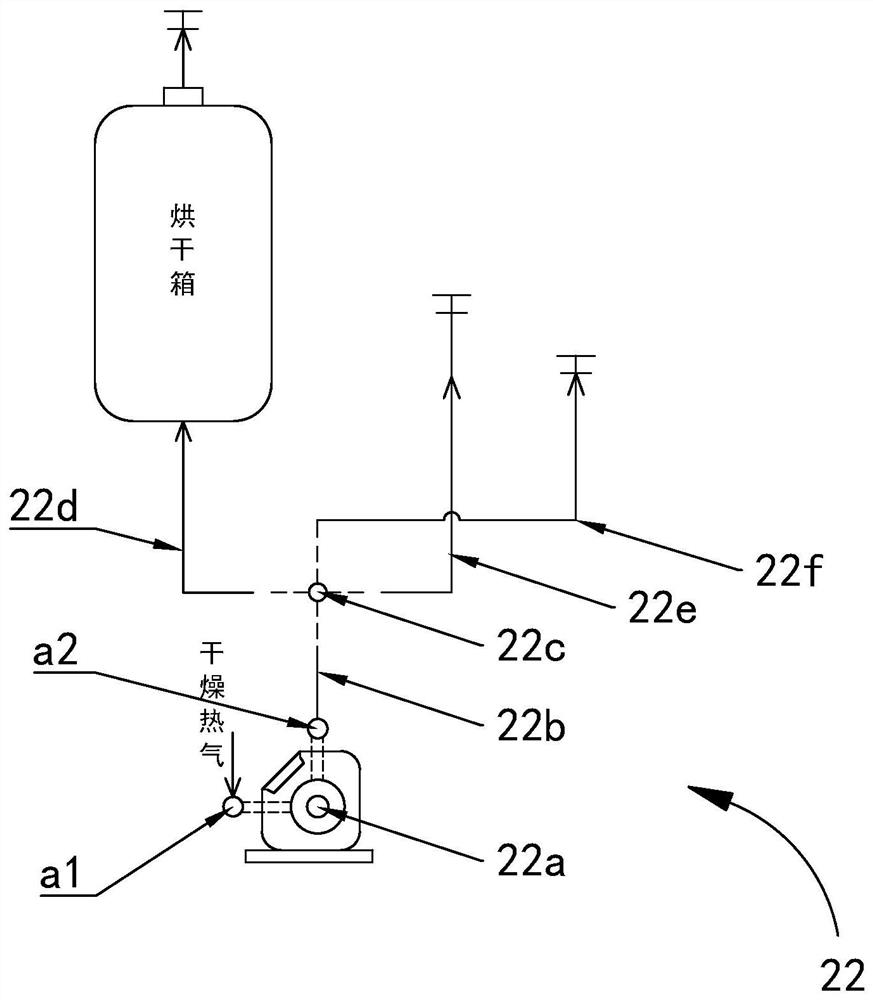

[0117] A3 Pre-adjustment: start the ventilation part, and the ventilation part inhales or evacuates the vacuum volume adjustment space;

[0118] A4 creping: the vacuum creping roller 13 and the drying cylinder 12 are pressed against each other, so that the paper web is adsorbed on the surface of the vacuum creping roller 13. The rotation speed of the vacuum creping roller 13 is lower than the rotation speed of the drying cylinder 12, resulting in a speed difference, and the wet paper The web is stacked and crimped at the squeeze of the vacuum creping roll 13 and the dryer 12;

[0119] A5 Drying: After the wrinkled paper w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com