Chlorine-permeation-resistant and mildew-proof film and preparation method and application thereof

A technology of resin and raw materials, which is applied in the field of anti-mold film and its preparation, and resistance to chlorine penetration. It can solve the problems of easy growth of mold on the surface of the membrane material, affect the normal use of swimming pools, and poor stability of the membrane material, and achieve good chlorine penetration resistance. , good adhesion and chlorine resistance, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

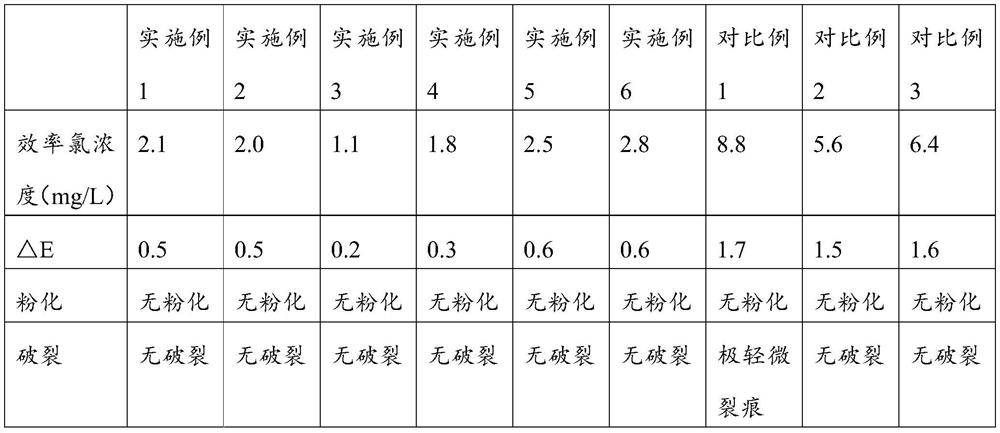

Examples

Embodiment 1

[0053] Embodiment 1: the preparation of chlorine permeation-resistant, mildew-proof film

[0054] A chlorine penetration-resistant, mildew-resistant film, the raw material components for preparing the film, in parts by weight, include 100 parts of polyvinyl chloride resin, 0.5 part of graphene oxide, 0.5 part of carbon nanotubes, 2 parts of nano-zinc oxide Parts, 30 parts of KH550 silane coupling agent, 50 parts of diisononyl phthalate, 3 parts of barium zinc stabilizer, 0.5 parts of 2-hydroxy-4-n-octyloxybenzophenone, 5 parts of light calcium carbonate share.

[0055] The preparation method of the above-mentioned chlorine-resistant permeation, mildew-proof film comprises the following steps:

[0056] (1) Banbury mixing: heat up each raw material component (heating temperature is 155° C.) and stir and mix. The stirring and mixing of each raw material component is through low-speed stirring and high-speed stirring. The stirring speed of low-speed stirring is 60 rpm. The time ...

Embodiment 2

[0059] Embodiment 2: the preparation of chlorine permeation-resistant, mildew-proof film

[0060] A chlorine penetration-resistant, mildew-resistant film, the raw material components for preparing the film, in parts by weight, including 90 parts of polyvinyl chloride resin, 1.5 parts of graphene oxide, 1.0 parts of carbon nanotubes, 4 parts of nano-zinc oxide 45 parts of gamma-glycidyl etheroxypropyl trimethoxysilane, 60 parts of diisononyl phthalate, 3 parts of barium zinc stabilizer, 0.6 parts of phenyl o-hydroxybenzoate, 5 parts of light calcium carbonate .

[0061] The preparation method of the above-mentioned chlorine-resistant permeation, mildew-proof film comprises the following steps:

[0062] (1) Banbury mixing: heat up each raw material component (heating temperature is 160°C) and stir and mix. The stirring and mixing of each raw material component is through low-speed stirring and high-speed stirring. The stirring speed of low-speed stirring is 70 rpm. The time is...

Embodiment 3

[0065] Embodiment 3: the preparation of chlorine penetration, mildew proof film

[0066] Compared with Example 1, there is an ink layer on the surface of the film in Example 3, and the thickness of the ink layer is 10 μm.

[0067] The ink components forming the ink layer include 15 parts of polyurethane modified epoxy resin, 15 parts of polyester resin, 1 part of silicone defoamer, 0.3 parts of carbon nanotubes, 1.5 parts of glyceryl tristearate, butyl acetate 64 parts, 0.5 parts of nano zinc oxide.

[0068] The preparation method of the ink is as follows: first mix the polyurethane modified epoxy resin, the polyester resin and butyl acetate respectively to obtain the polyurethane modified epoxy resin mixture and the polyester resin mixture, and then mix the polyurethane modified epoxy resin mixture and Add the remaining components to the polyester resin mixture, stir and mix, the stirring speed is 400 rpm, and the stirring time is 1 hour, and the ink is prepared.

[0069] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com