Preparation method for producing high-organic-nitrogen liquid organic fertilizer by utilizing livestock and poultry died of diseases

A technology for liquid organic fertilizer and dead livestock and poultry is applied in the field of producing high-organic nitrogen liquid organic fertilizer by using dead livestock and poultry, can solve the problems of reduced organic nitrogen content, low fertilizer efficiency and the like, and achieves high utilization efficiency, short time-consuming, The effect of convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

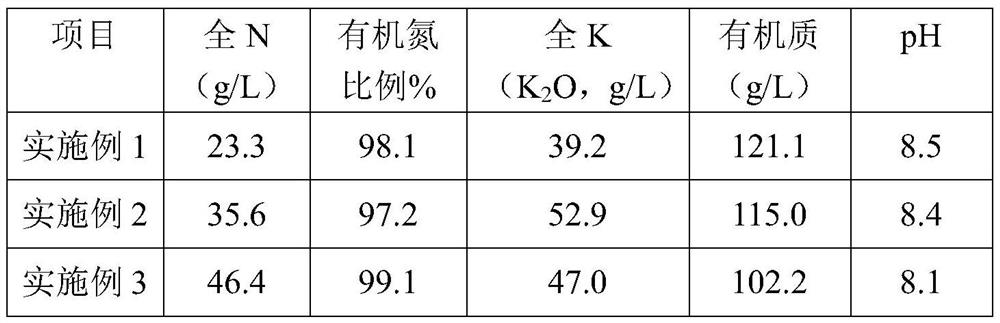

Embodiment 1

[0022] The preparation method of utilizing dead livestock and poultry of the present embodiment to produce high organic nitrogen liquid organic fertilizer comprises the following steps:

[0023] (1) Freeze and temporarily store the collected carcasses of sick and dead poultry and animal slaughtering leftovers, and crush them after reaching a certain amount (500kg) or more to obtain 3-5cm square debris;

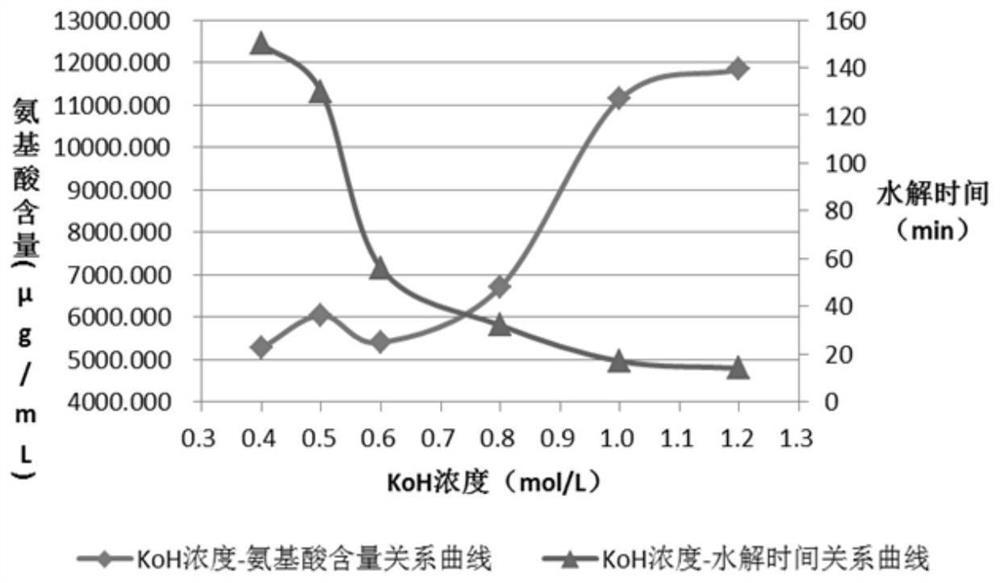

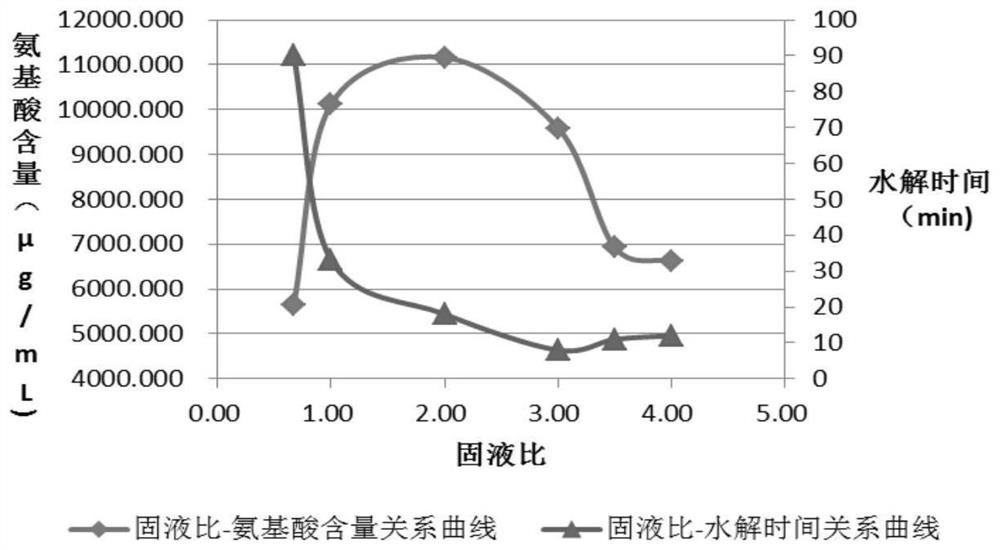

[0024] (2) Put the debris into the alkali-resistant reaction kettle, and then add a potassium hydroxide solution with a concentration of 1.1.0mol / L according to the mass of the solid-liquid ratio of 1:5, and control the total volume of the charge to account for the effective volume of the alkali-resistant reaction kettle Then turn on the switch of the alkali-resistant reactor to heat up to 100°C, and stir slowly at 100°C under normal pressure (stirring rate is 2 to 3 revolutions / min) for 2 hours. Under this condition, the debris in the The meat, fat, hair, horns, hooves, etc. ...

Embodiment 2

[0028] The preparation method of utilizing dead livestock and poultry of the present embodiment to produce high organic nitrogen liquid organic fertilizer comprises the following steps:

[0029] (1) Freeze and temporarily store the collected carcasses of sick and dead poultry and animal slaughtering leftovers, and crush them after reaching a certain amount (500kg) or more to obtain 3-5cm square debris;

[0030] (2) Put the debris into the alkali-resistant reaction kettle, and then add a potassium hydroxide solution with a concentration of 1.5mol / L according to the mass of the solid-liquid ratio of 1:3, and control the total volume of the charge to account for the effective volume of the alkali-resistant reaction kettle. 70% or so; then turn on the switch of the alkali-resistant reactor to heat up to 100°C, and stir at a slow speed (stirring rate of 2 to 3 revolutions / min) at 100°C and normal pressure for 1.5h. The meat, fat, hair, horns, hooves, etc. are completely liquefied a...

Embodiment 3

[0034] The preparation method of utilizing dead livestock and poultry of the present embodiment to produce high organic nitrogen liquid organic fertilizer comprises the following steps:

[0035] (1) Freeze and temporarily store the collected carcasses of sick and dead poultry and animal slaughtering leftovers, and crush them after reaching a certain amount (500kg) or more to obtain 3-5cm square debris;

[0036] (2) Put the debris into the alkali-resistant reaction kettle, and then add a potassium hydroxide solution with a concentration of 1.5mol / L according to the mass ratio of solid-liquid ratio of 1:2, and control the total volume of the charge to account for the effective volume of the alkali-resistant reaction kettle Then turn on the switch of the alkali-resistant reactor to heat up to 100°C, and stir slowly at 100°C under normal pressure (stirring rate is 2 to 3 revolutions / min) for 2.0h. Under this condition, the debris The meat, fat, hair, horns, hooves, etc. in the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com