Sliding type air inlet ventilation mechanism of airplane auxiliary power unit

An aircraft auxiliary power and sliding technology, which is applied in the direction of auxiliary power equipment, aircraft parts, air handling equipment, etc., can solve the problems of difficult layout and structure installation, large air intake, and large power of aircraft auxiliary power devices. , to achieve the effect of flexible arrangement position and method, large opening area, flexible actuator selection and arrangement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

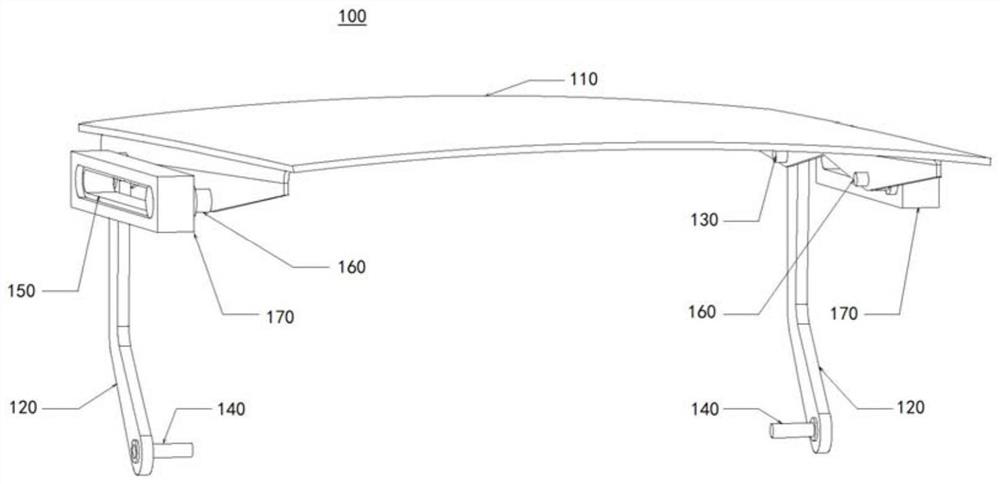

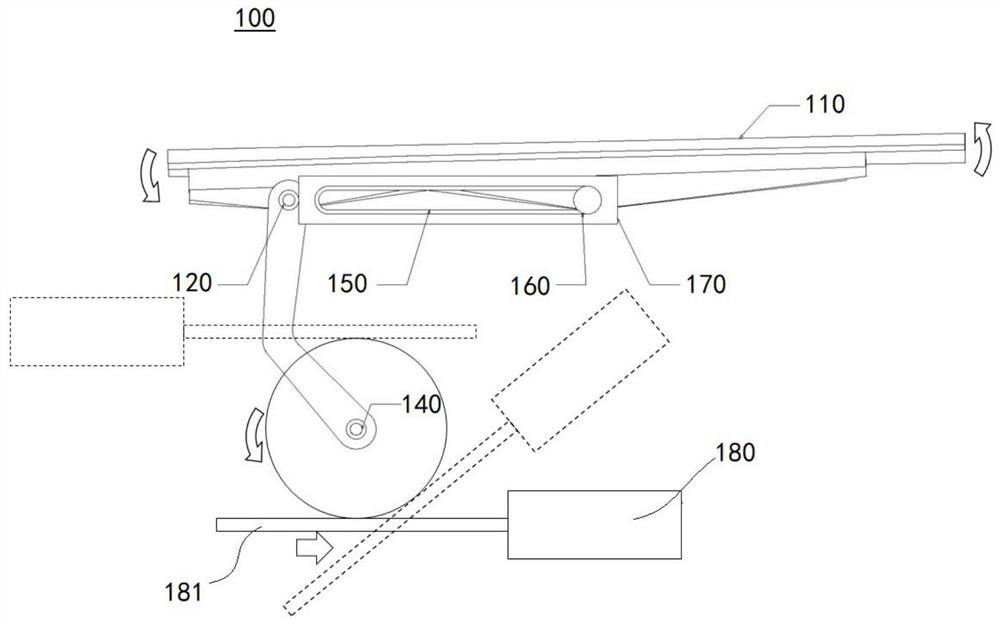

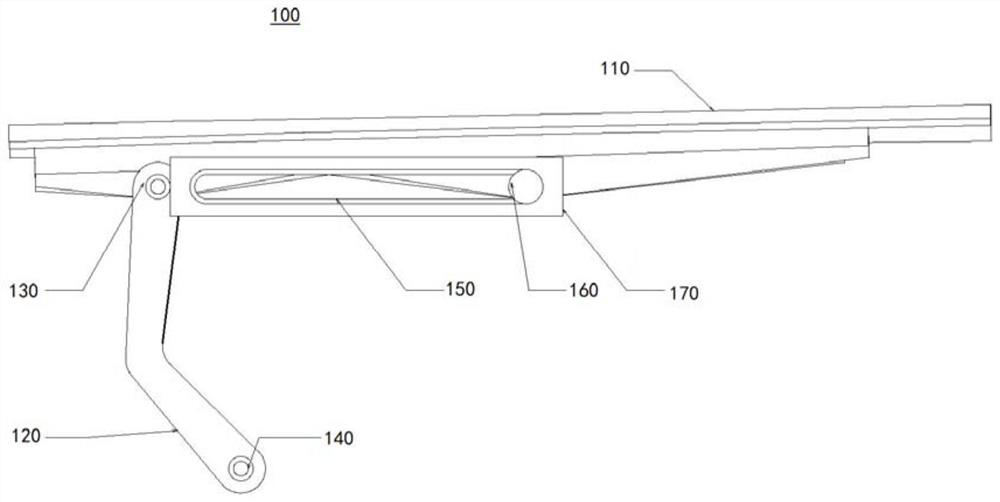

[0047] Below, refer to figure 1 and figure 2 , the sliding air intake ventilation mechanism 100 of the aircraft auxiliary power unit of the present invention will be described in detail. figure 1 It is a perspective view of the composition of the sliding intake ventilation mechanism 100 of an aircraft auxiliary power unit according to an embodiment of the present invention, wherein the driving mechanism (intake valve actuator) included in the sliding intake ventilation mechanism 100 is not shown , figure 2 It is a schematic diagram showing the arrangement of the driving mechanism (intake valve actuator) with respect to the intake valve 110 and the transmission mechanism in the sliding intake ventilation mechanism 100 according to one embodiment of the present invention.

[0048] Such as figure 1 As shown, the sliding intake and ventilation mechanism 100 of the aircraft auxiliary power unit of the present invention includes an intake valve 110 whose curved shape matches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com