Aircraft engine exhaust funnel circular seam laser welding clamp and welding method

A technology for laser welding fixtures and aircraft engines, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve problems such as difficulty in loading and unloading aircraft engine exhaust pipes, achieve reliable inert gas protection, ensure docking accuracy, and weld quality best results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

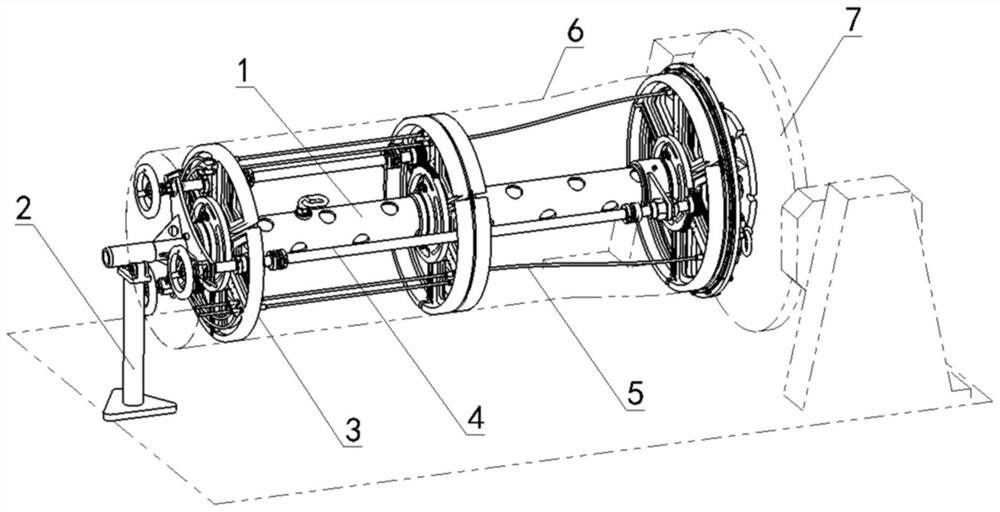

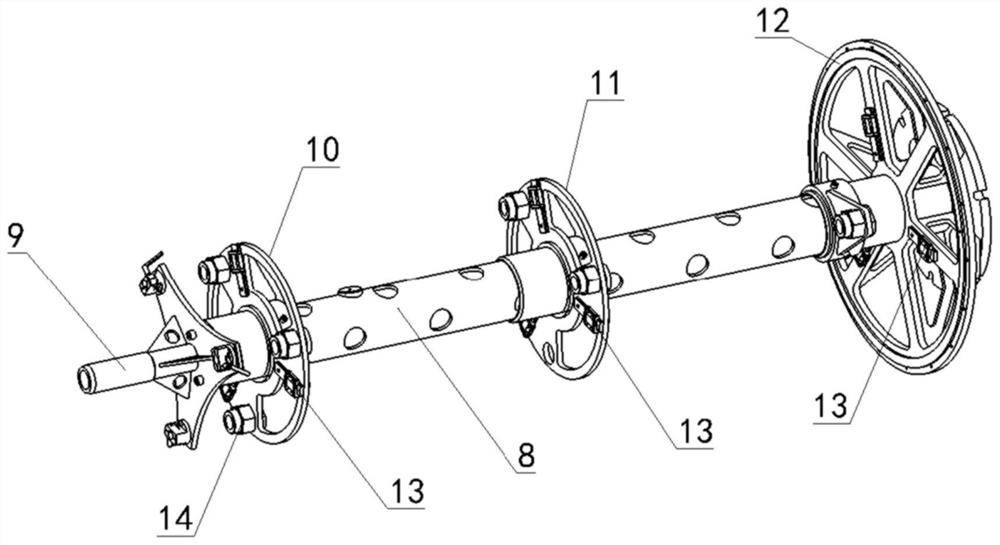

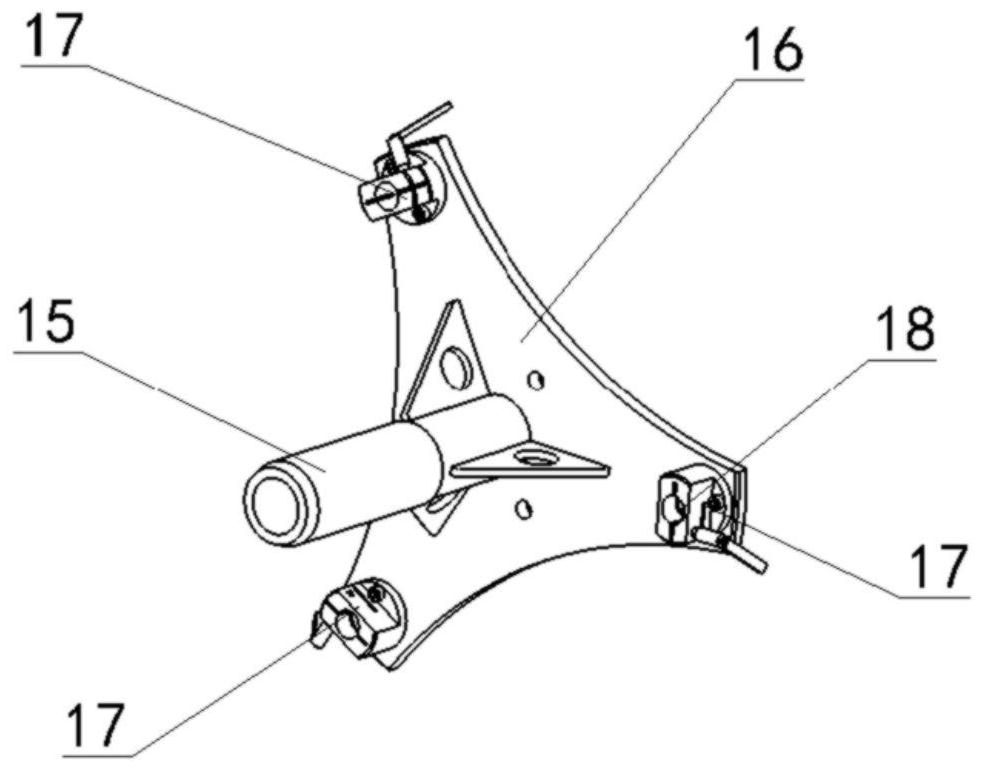

[0028] See figure 1 - Figure 8 A aircraft engine exhaust cartridge sewing laser welding clamp comprising the spindle structure 1, the adjustable support 2, the positioning disk structure 3, the positioning disk drive mechanism 4, the gas protection device 5, the main shaft structure 1 end and the machine tool 7 working turntable connection The main shaft structure 1 is driven by the machine tool 7, and the other end is connected to the adjustable support 2; the positioning disk structure 3 axial sleeve is connected to the main shaft structure 1, and radially through the slide slider 12 and the main shaft structure 1; positioning disk drive mechanism 4 Mounting on the spindle structure 1, driving the different diameter of the positioning disk structure 3, the gas protection device 5 is mounted on the positioning disk structure 3, and is connected to the main shaft structure 1, providing inert gas protection for different weld back The aircraft engine exhaust cartridge 6 is position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com