An electric adjustment tray used in the engine production process

A production process and electric adjustment technology, which is applied in the direction of machine containers, assembly machines, rigid containers, etc., can solve the problems of reduced production efficiency, increased production costs, and inability to realize flexible production, so as to improve production efficiency and reduce manufacturing costs , precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

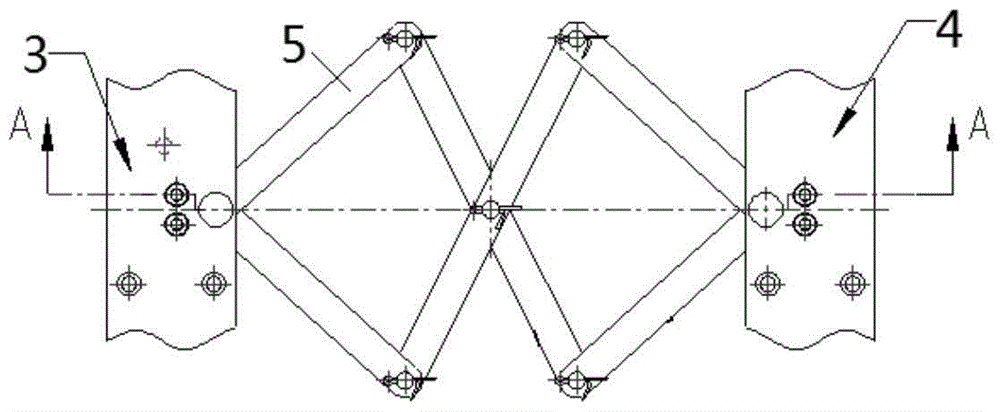

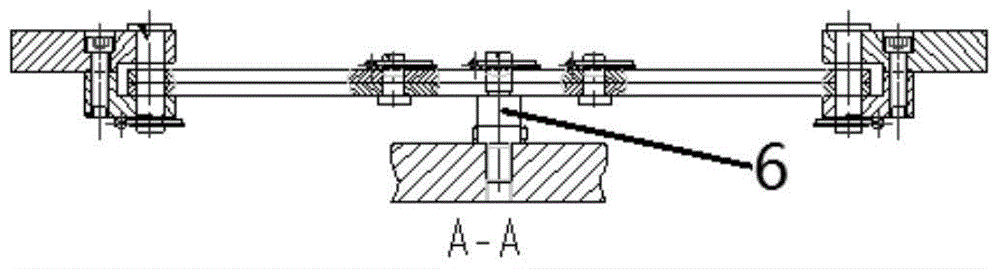

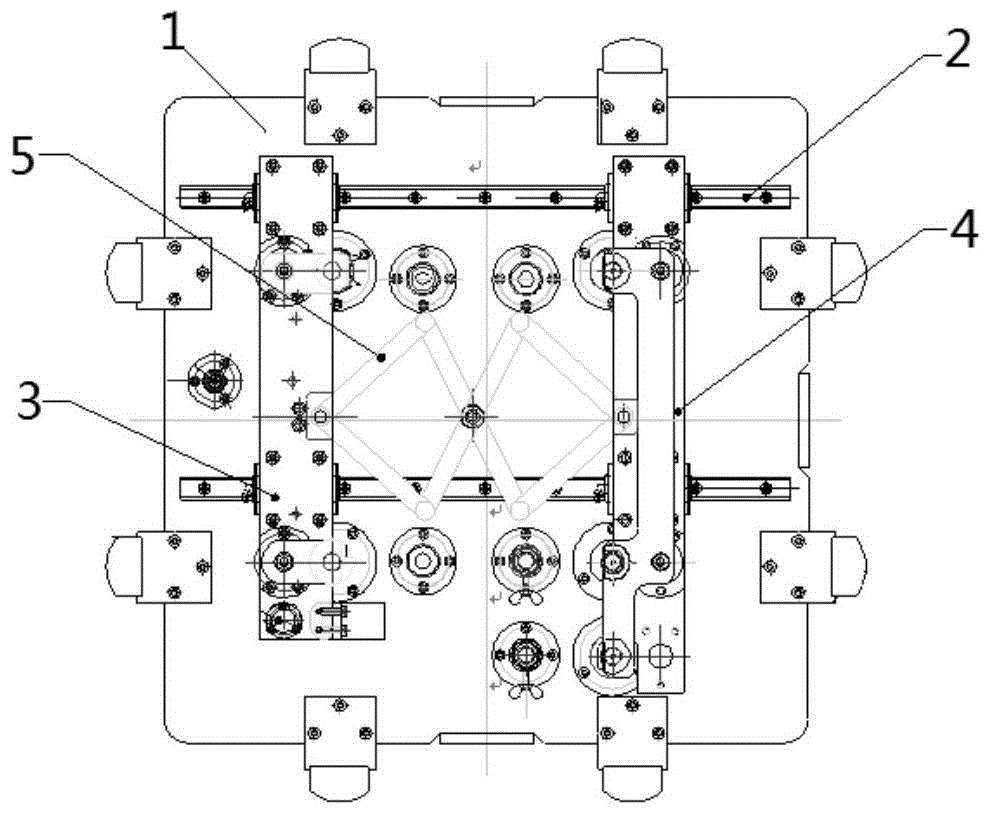

[0025] The technical solution to be provided by the present invention is an electric adjustment tray used in the engine production process, including a tray bottom plate 1 and a support column, the lower surface of the tray bottom plate 1 is provided with a hinge connection mechanism, and the tray bottom plate 1 passes through the The hinge connection mechanism is connected to the hinge of the engine production line; the tray is provided with a micro-accumulator and a central micro-control computer, and the micro-accumulator is connected to the central micro-control computer; the tray bottom plate 1 and the support column A lateral displacement system is provided. The lateral displacement system includes a slide assembly and a linear guide rail 2. The sliding direction of the slide assembly is perpendicular to the running direction of the pallet on the production line. The lateral displacement system also includes an electronic stroke control device, the electronic stroke contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com