Light spot homogenizing system and method for laser soldering

A laser welding and spot technology, applied in the field of lasers, can solve the problems of affecting welding quality and uneven heating, and achieve the effect of good roundness, ensuring welding quality and uniform energy distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

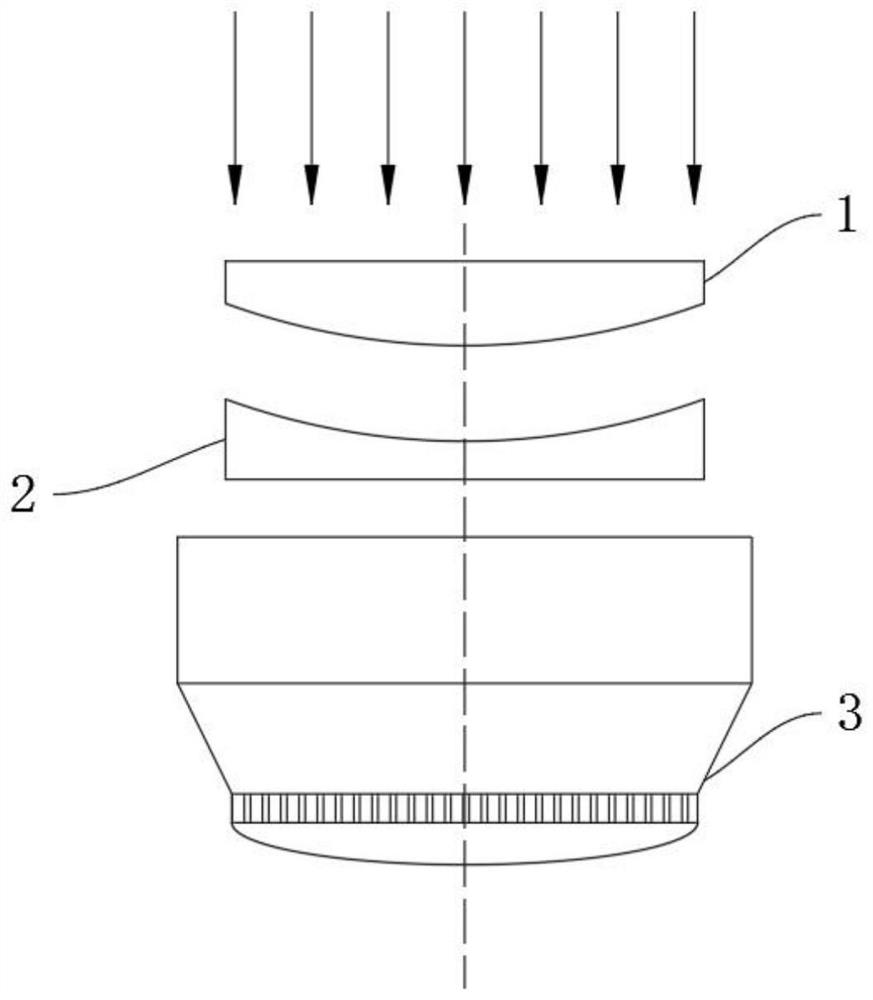

[0019] Example: see figure 1 , the invention provides a spot homogenization system for laser soldering, including a beam shaping component for homogenizing a collimated beam, and the beam shaping component sequentially includes a homogenizing lens group and a laser condenser lens along the advancing direction of the optical path Head 3, the main optical axis of the homogenizing lens group and the main optical axis of the laser condensing lens 3 coincide with the emission direction of the collimated beam, and the homogenizing lens group includes convex lens 1 and concave lens 2, convex lens 1 and concave lens 2 in sequence along the direction of optical path advancement interval setting.

[0020] The convex lens 1 is a plano-convex convex lens, and the concave lens 2 is a plano-concave concave lens. The convex surface of the convex lens 1 matches the concave surface of the concave lens 2, and the convex surface of the convex lens 1 and the concave surface of the concave lens 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com