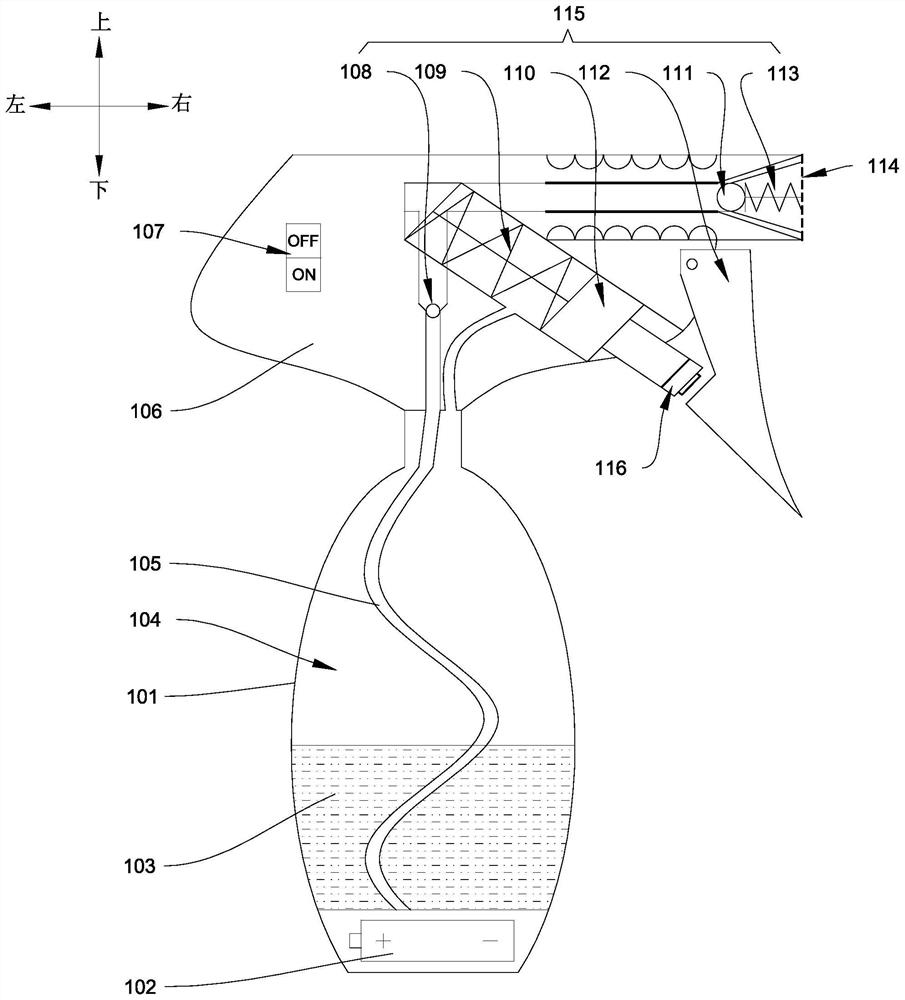

Disinfectant fluid preparation device

A technology for preparing device and disinfecting water, applied in water supply devices, disinfection, spraying devices, etc., can solve the problems of affecting the disinfection effect, easy deterioration of disinfection water, short validity period of disinfection water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

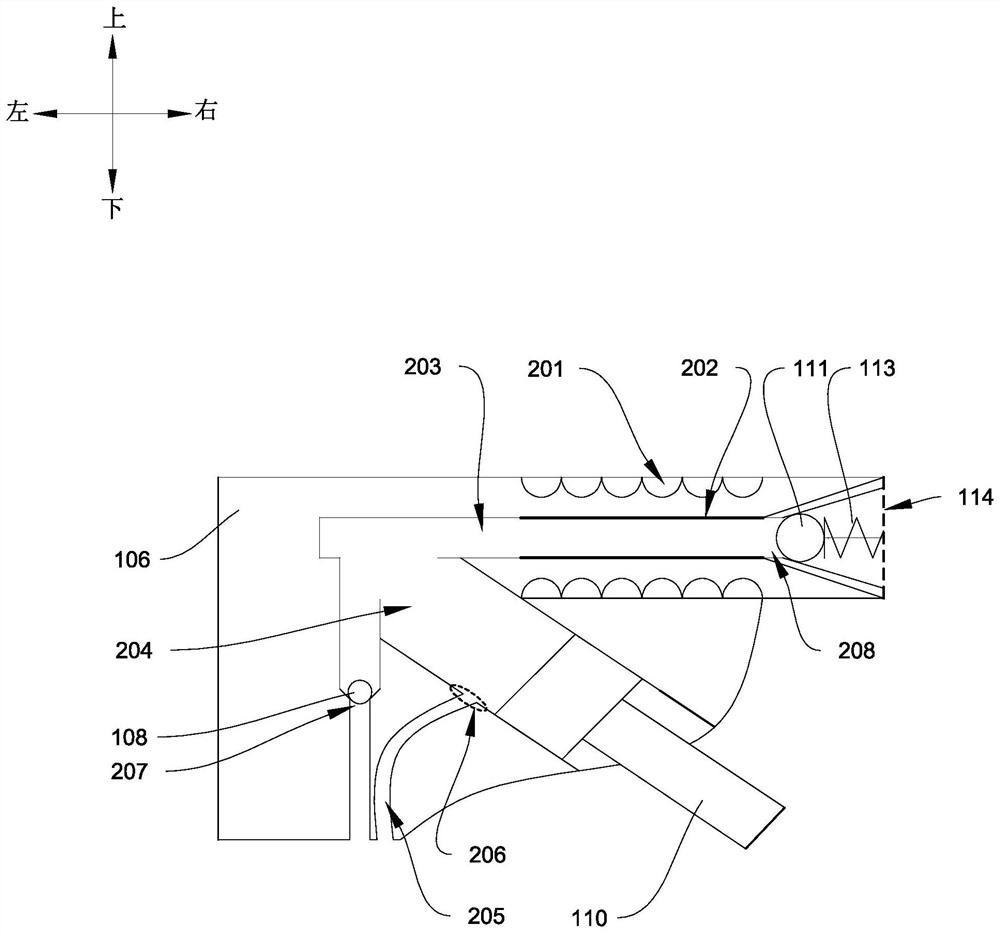

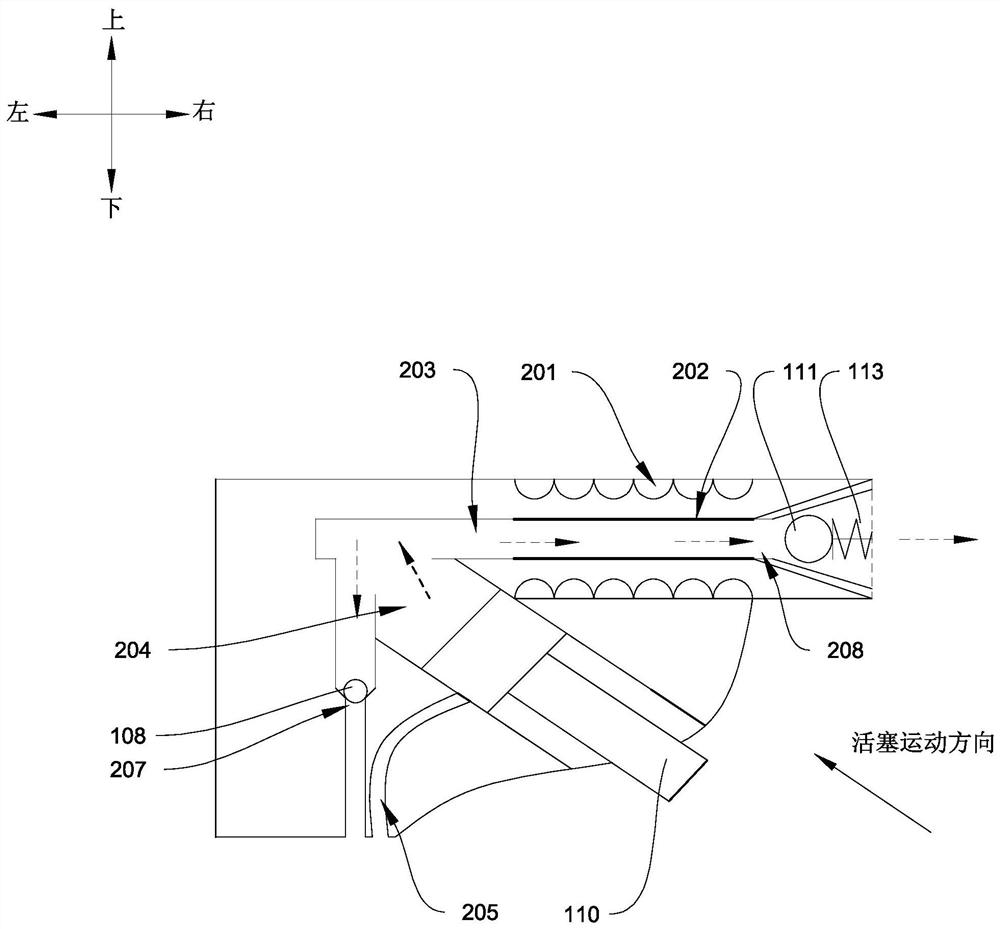

[0034] Based on the above structure, the disinfectant water preparation device can be configured to activate the disinfectant element 202 by ambient light (such as sunlight). Specifically, at least a part of the base 106 is transparent, allowing ambient light to irradiate the sterilizing element 202 on the wall of the main channel 203 , so that the sterilizing element 202 works. This arrangement does not need to set up a light source for exciting the sterilizing element 202, and the structure of the device is simpler and the cost is lower.

no. 2 example

[0036] This embodiment is similar to the first embodiment, the main difference is that the disinfectant water preparation device also includes an activation lamp 201 , and the light of the activation lamp 201 can irradiate the disinfection element 202 on the wall surface of the main channel 203 . That is, the disinfection water preparation device in this embodiment excites the disinfection member 202 through the light emitted by its own lamp. Specifically, the excitation lamp 201 can be set as an ultraviolet lamp, and the excitation lamp 201 emits medium and long-wave ultraviolet rays, and the ultraviolet wavelength is between 280-400nm. This setting has less restrictions on the use environment of the device, and the device has higher flexibility in use.

[0037] It should be noted that, in order to enable the light of the excitation lamp 201 to irradiate the sterilizing part 202, the light emitting side of the activating lamp 201 needs to face the sterilizing part 202, and a ...

no. 3 example

[0039] This embodiment is equivalent to the combination of the first embodiment and the second embodiment. In this embodiment, the disinfectant water preparation device can either activate the disinfection element 202 through ambient light, or activate the disinfection element 202 through the light of the excitation lamp 201 . In this embodiment, the disinfectant water preparation device includes an excitation lamp 201, and the light of the excitation lamp 201 can be irradiated to the disinfection piece 202 on the wall surface of the main flow channel 203; . When the ambient light is sufficient, the excitation lamp 201 may not be turned on, and there is no need to supply power to the excitation lamp 201; when the ambient light is insufficient, the excitation lamp 201 is turned on. The disinfectant water preparation device of this embodiment has high flexibility and low energy consumption.

[0040] Accordingly, refer to Image 6 or Figure 7 , the position of the excitation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com