Biomass liquid fuel production device

A technology of liquid fuel and production equipment, which is applied in the direction of mixers, dissolvers, and mixers with rotating stirring devices, which can solve problems such as reducing performance, hindering liquid flow rate, and affecting filtration efficiency, achieving high filtering effect and ensuring flow rate , Improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

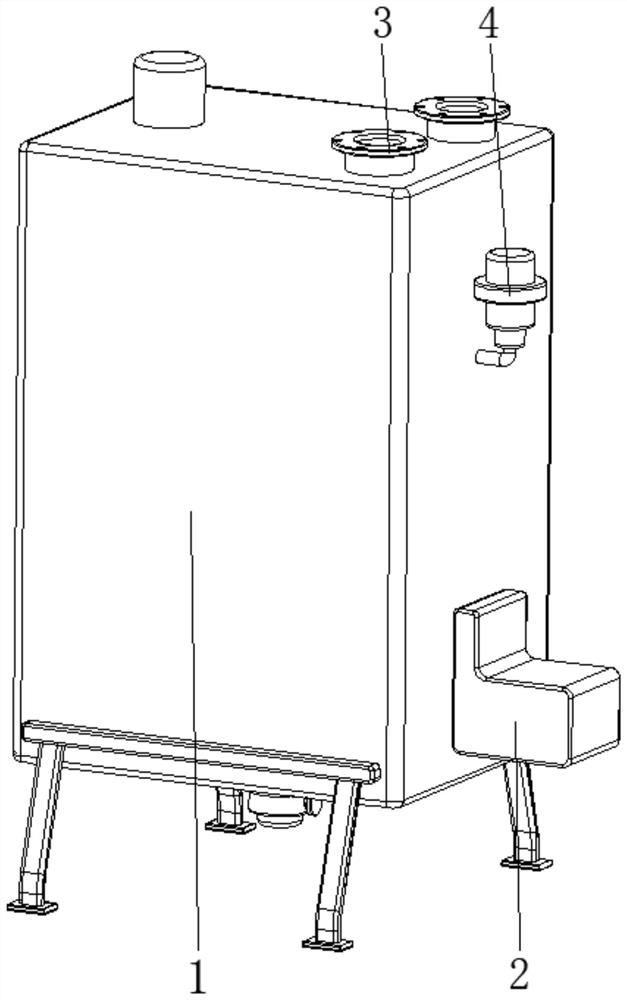

[0030] see Figure 1-6 , the present invention provides a technical solution: a biomass liquid fuel production device, including a housing 1, a power mechanism 2, a feed port 3, and an air pump 4, the power mechanism 2 is arranged on the bottom side of the surface of the housing 1, and The feed port 3 is fixed and connected to the top side of the shell 1, and the air pump 4 is set on the top side of the shell 1;

[0031] The interior of the housing 1 is provided with a filter device 5, a slag discharge port 6, and a mixing device 7. The filter device 5 is arranged inside the shell 1 and is close to the central position. The filter device 5 is connected with the air pump 4, and the slag discharge port 6 is set on one side of the surface of the housing 1 and is located at the position of the filter device 5. The mixing device 7 is arranged inside the housing 1 and is located at the bottom of the filter device 5. The mixing device 7 is connected with the power mechanism 2, which ...

Embodiment example 2

[0033] The filter device 5 is provided with a filter screen main body 51, an arc-shaped conical protrusion 52, and a cleaning device 53. The surface edge of the filter screen main body 51 is fixedly connected with the inner wall of the housing 1, and the arc-surface conical protrusion 52 is arranged on the filter screen main body. 51, the removal device 53 is arranged at the center of the surface of the arc-shaped conical protrusion 52, when the raw material passes through the filter screen main body 51, the residue can be filtered out, and the air pump 4 is used to deliver high-pressure gas, so that the removal device 53 work, and the arc-shaped conical protrusion 52 can cooperate with the mixing device 7 to make full use of its own rotation, so that when mixing materials, it can further perform self-cleaning, and the situation of blockage is not easy to occur.

[0034]Clearing device 53 is provided with base body 531, main air channel 532, spherical inner cavity 533, impact b...

Embodiment example 3

[0036] The mixing device 7 is provided with a rotating roller 71, a stirring rod 72, and a scraping device 73. The end of the rotating roller 71 is connected in rotation with the inner wall of the housing 1, and one end of the rotating roller 71 penetrates the inner wall of the housing 1 and extends to it. Externally, one end of the rotating roller 71 extending to the outside of the housing 1 is connected with the power mechanism 2, one end of the stirring rod 72 is fixedly connected to the surface of the rotating roller 71, and the scraping device 73 is arranged on the side of the stirring rod 72 away from the rotating roller 71. At one end, when the power mechanism 2 drives the rotating roller 71, the stirring rod 72 and the scraping device 73 will rotate accordingly, and then use the staggered arrangement to improve the stirring efficiency of the material liquid, so that the material can be mixed quickly and evenly At the same time, when the scraping device 73 is rotating, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com