Plate-and-frame driving mechanism and plate-and-frame filter pressing device

A driving mechanism, plate and frame technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as air or oil leakage of driving cylinders or oil cylinders, affecting normal operation of equipment, and corroding piston rods, etc., to achieve Smooth flow, reduced processing cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

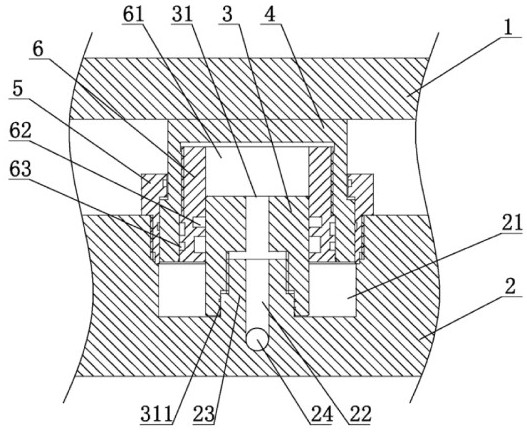

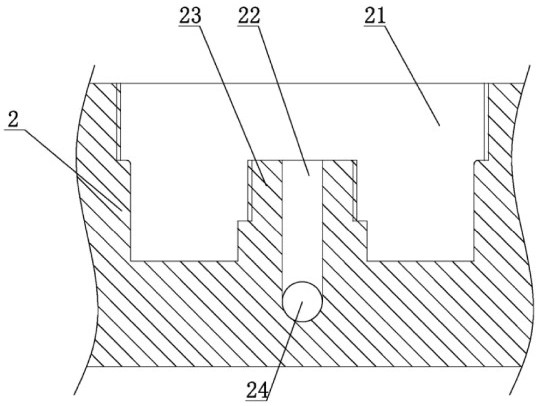

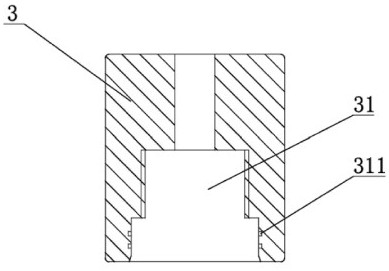

[0054] like Figure 1 to Figure 7 As shown, the plate and frame driving mechanism of the present embodiment includes a pushing plate 1 and a pressure bearing plate 2, and several housing piston spaces 21 for installing the driving mechanism are provided around the pressure bearing plate 2, and the upper end of the housing piston space 21 is connected to the gland 5 . The driving mechanism includes a piston rod 3, a guide sleeve 6 and a housing 4. The housing 4 is processed with internal threads, and the outer side of the matching guide sleeve 6 is processed with external threads. The guide sleeve 6 is threadedly connected to the housing 4 through internal threads and external threads. Inside, the piston rod 3 passes through the guide hole 61 provided in the guide sleeve 6, and the inner and outer sides of the guide sleeve 6 are respectively provided with an inner seal groove 62 and an outer seal groove 63, and the seal between the piston rod 3 and the guide sleeve 6 is install...

Embodiment 2

[0057] like Figure 8 , Figure 9 As shown, the housing 4 and the guide sleeve 6 can also be integrally connected, the housing 4 and the guide sleeve 6 can further reduce the installation space, and there is no need to process the outer sealing groove 63, and the third sealing ring is not used, further reducing the production cost.

[0058] The outside of the housing 4 can be coated with corrosion-resistant materials, which can improve the corrosion resistance of the housing 4 .

[0059] The pressure can be hydraulic oil or high pressure gas.

[0060] When the plate and frame driving mechanism of this embodiment is installed, the piston rod 3 is first screwed to the boss 23 of the housing piston space 21 of the pressure bearing plate 2, and then the guide sleeve 6 is screwed into the housing 4, and the connection is completed. Then the guide sleeve 6 and the housing 4 are sleeved and connected to the outside of the piston rod 3, and finally the gland 5 is connected to the pi...

Embodiment 3

[0062] like Figure 10 As shown, in another embodiment, the boss 23 of the pressure bearing plate 2 may not be provided with an external thread, but an internal thread may be provided in the pressure medium passage 22, and after the piston rod 3 is inserted into the boss 23 , by tightening the hollow bolt 7 into the pressure medium passage 22 to realize the fixed connection between the piston rod 3 and the boss 23; The piston rod 3 and the boss 23 are connected and fixed by the hollow bolt 7, which can reduce the processing difficulty of the pressure bearing plate 2 and reduce the processing cost.

[0063] like Figure 11 As shown, in another embodiment, the housing 4 may not be provided with the guide sleeve 6 , and the housing 4 is directly sleeved on the outside of the piston rod 3 . The outer circumference of the lower part of the housing 4 can also be provided with an outer ring groove 41, and an outer support ring 8 is arranged in the outer ring groove 41, which can im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com