Nut picking machine

A picking machine and nut technology, applied in the field of nut picking equipment, can solve the problems of affecting the picking head, impacting branches, jamming the main body, etc., and achieve the effect of improving transmission efficiency, reducing the impact, and avoiding the main jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

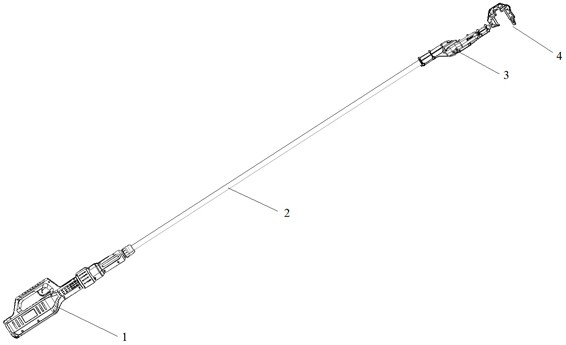

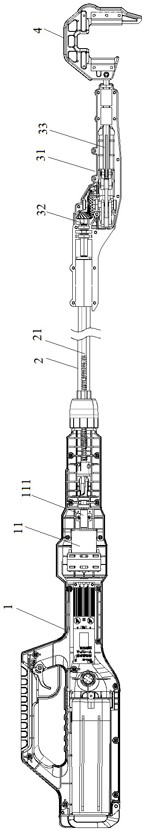

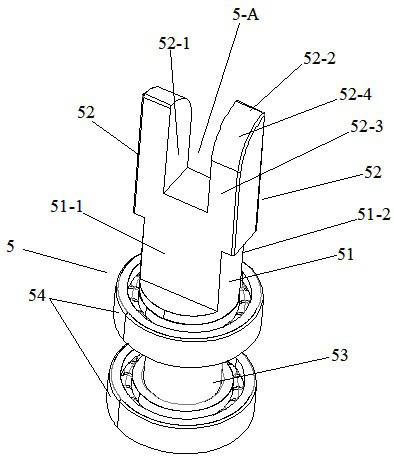

[0046] refer to Figure 1-Figure 6 , a nut picking machine, comprising a tail case 1, a machine rod 2, and a machine head 3. A driving motor 11 is arranged in the tail case 1; the machine rod 2 extends along the front-to-back direction, one end thereof is assembled and fixed with the tail case 1, and the other end is assembled and fixed with the machine head 3; The transmission shaft 21, the output shaft 111 of the drive motor 11 extends forward and backward, and is connected with the transmission shaft 21. If a plurality of transmission shafts 21 are set, the head and tail transmission connection of the plurality of transmission shafts 21; the machine head 3 includes the head shell Body 31, the crank link mechanism 32 positioned in the head housing 31, the picking head 4 positioned at the front of the head housing 31 and used to hook up branches, the head housing 31 is provided with a reciprocating movement bar extending forward and backward 33. The reciprocating rod 33 prot...

Embodiment example 2

[0063] refer to Figure 7-Figure 13 , a reciprocating impact head, including a head housing 31, a crank linkage 32, a balance connector 6, a reciprocating rod 33, a picking head 4, a crank linkage 32, a balance connector 6 and a reciprocating rod 33 is arranged in the machine head housing 31, the transmission shaft 21 is inserted from the rear end of the machine head housing 31 along the front and rear directions, and the balance connector 6 is fixedly connected to the rear end of the reciprocating moving rod 33, and the crank link mechanism 32 will The transmission shaft 21 and the balance connector 6 are connected by transmission, and are used to convert the rotation of the transmission shaft 21 into the front and rear linear reciprocating movement of the reciprocating rod 33 and the balance connector 6. The reciprocating rod 33 extends from the front end of the machine head housing 31. out, and its front end is fixedly connected to the picking head 4. After the picking hea...

Embodiment example 3

[0084] refer to Figure 14-Figure 16 , a kind of picking implement that conveniently hooks up branch, comprises reciprocating movement rod 33, is connected in the picking head 4 of reciprocating movement rod 33 front ends. The reciprocating rod 33 in this embodiment is the same as that of Embodiments 1 and 2, and it all moves back and forth linearly along its axial direction.

[0085] Picking head 4 comprises the picking forearm 41 that is spaced apart front and back, picks back arm 42 and the picking connecting beam 43 that connects both roots, forms the hooking mouth that hooks branch between picking the forearm 41 and picking the end of back arm 42 4-j. The picking forearm 41, the picking back arm 42 and the picking connecting beam 43 are integrally injection molded, and the material used is nylon with glass fiber added. With the increase of glass fiber content, the tensile strength and bending strength of the material are greatly improved. It can meet the physical perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com