Wine grape stem vibration separation test bench

A technology of vibration separation and test bench, which is applied in the field of agricultural machinery, can solve the problems of unfavorable sensor installation, spending a lot of time disassembling and assembling the sensor, and difficult adjustment of the sensor position, so as to achieve the effect of saving time and labor, convenient change and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

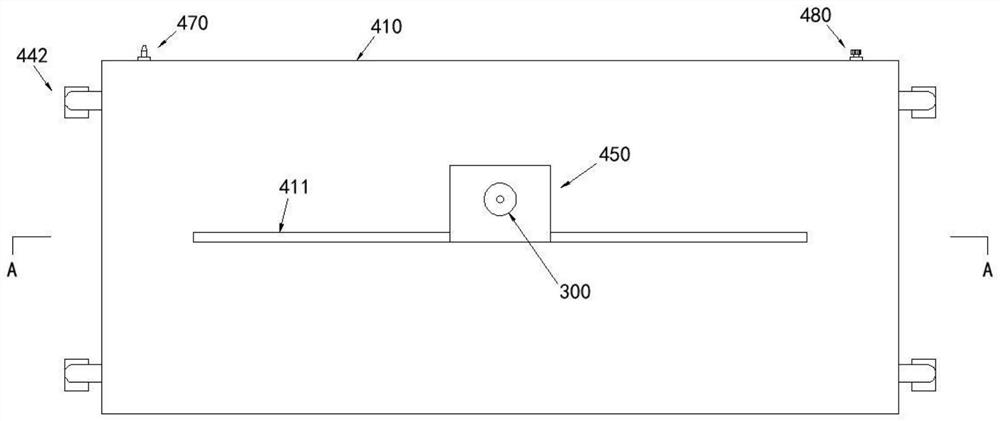

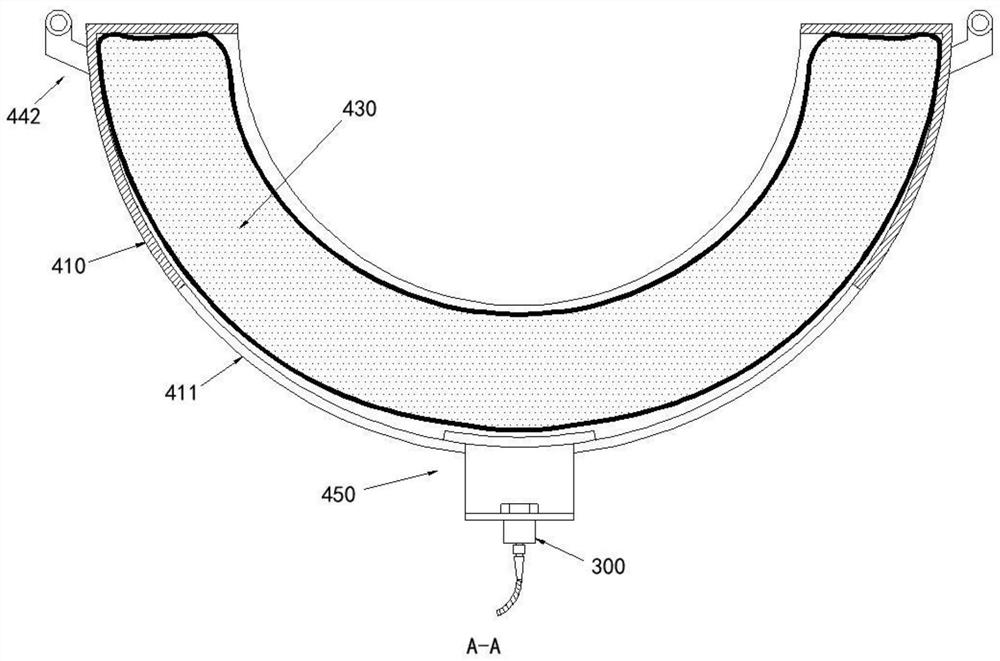

[0033] Such as Figure 1 to Figure 9 As shown, the wine grape fruit stem vibration separation test bench of the present embodiment includes a frame 100, a vibration mechanism 200, a data collector, a sensor 300, a fixed ring 400 and an air pump 500;

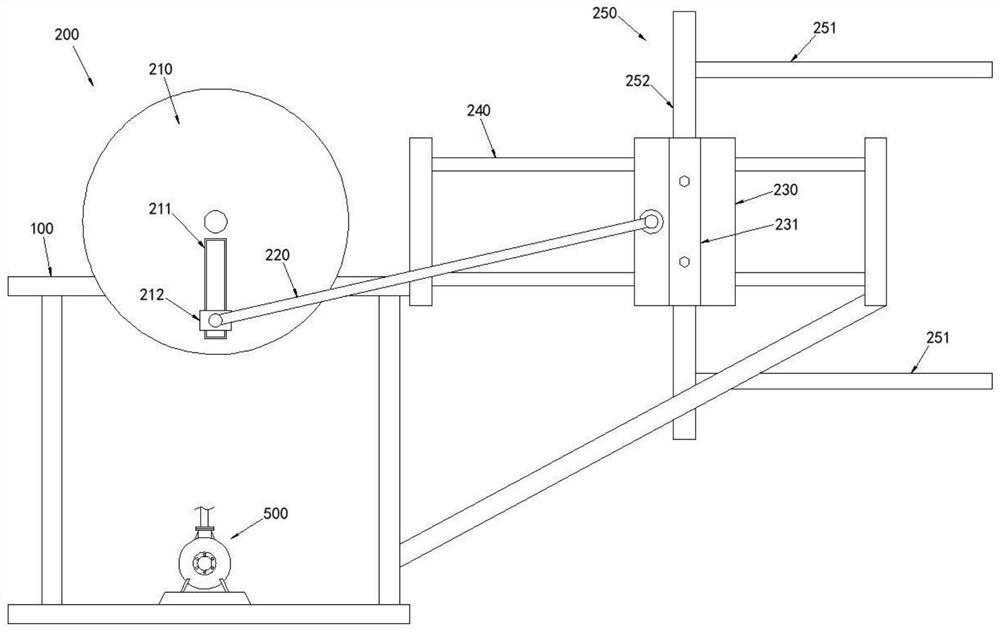

[0034] Such as figure 1 As shown, the vibration mechanism 200 includes a motor, a turntable 210, a connecting rod 220, a slider 230, a slide rail 240 and a second connecting rod 250. The motor is a variable frequency motor, and the motor drives the turntable 210 to rotate. Fixing groove 211, is provided with connecting block 212 in fixing groove 211, and one end of connecting rod 220 is hinged with connecting block 212, and the other end is hinged slider 230; Slider 230 is installed on the slide rail 240, and the second connecting rod 250 comprises two A horizontal bar 251 and a vertical bar 252, one end of the horizontal bar 251 is fixed on the vertical bar 252, the two horizontal bars 251 are parallel, the slider 230 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com