Secondary explosion-proof battery steel shell

A battery steel shell and outer shell technology, applied in the direction of battery cover/end cover, battery pack components, circuits, etc., can solve the problems of slow pressure relief of explosion-proof caps, explosion of battery steel shells, heating of battery cells, etc., to achieve Avoid chain explosion, easy to replace, and ensure the effect of electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

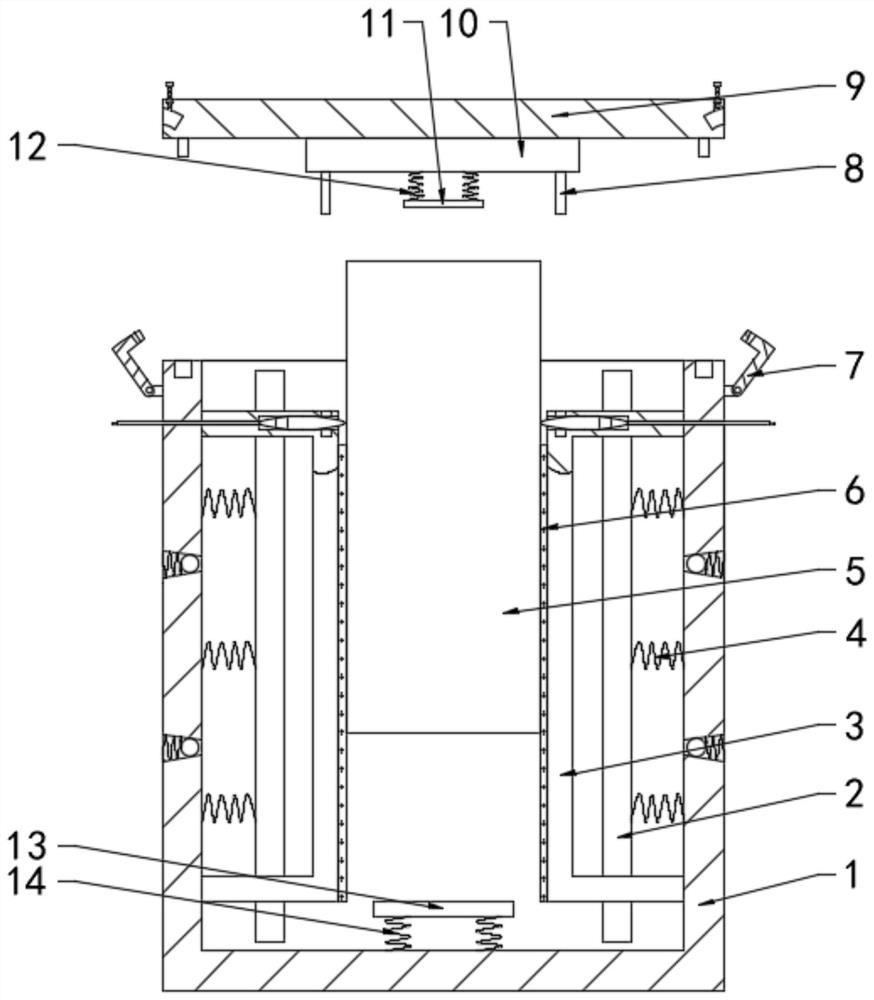

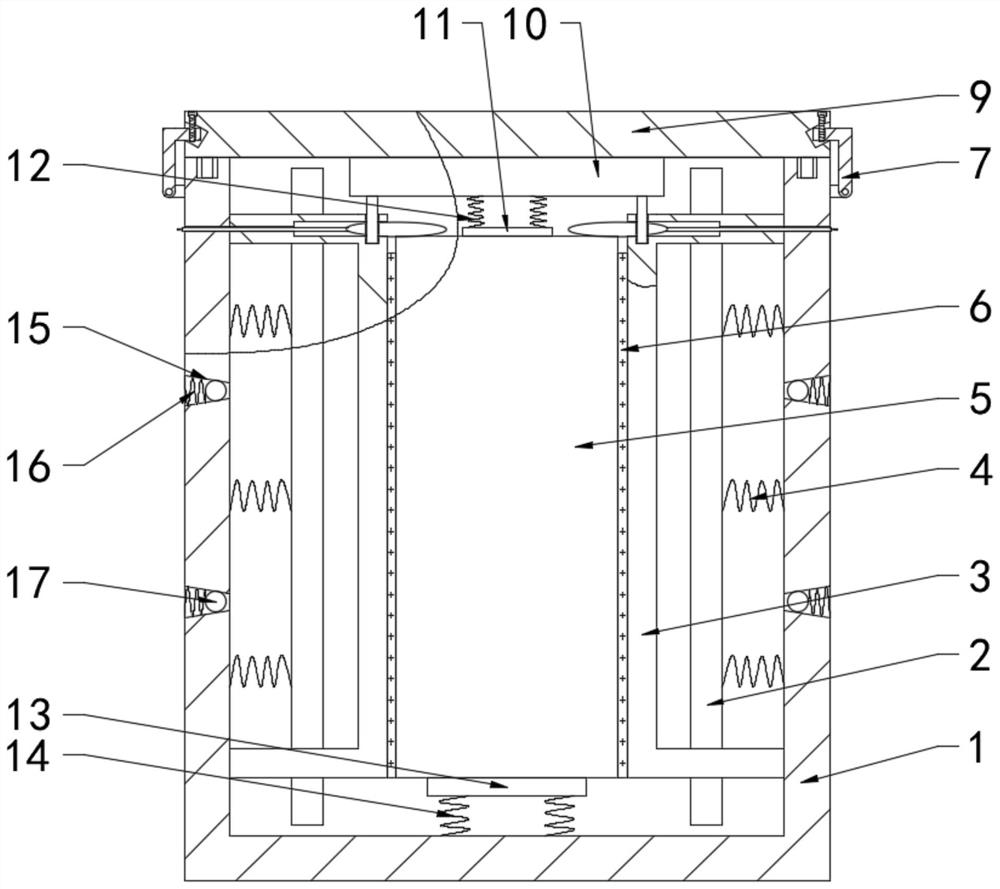

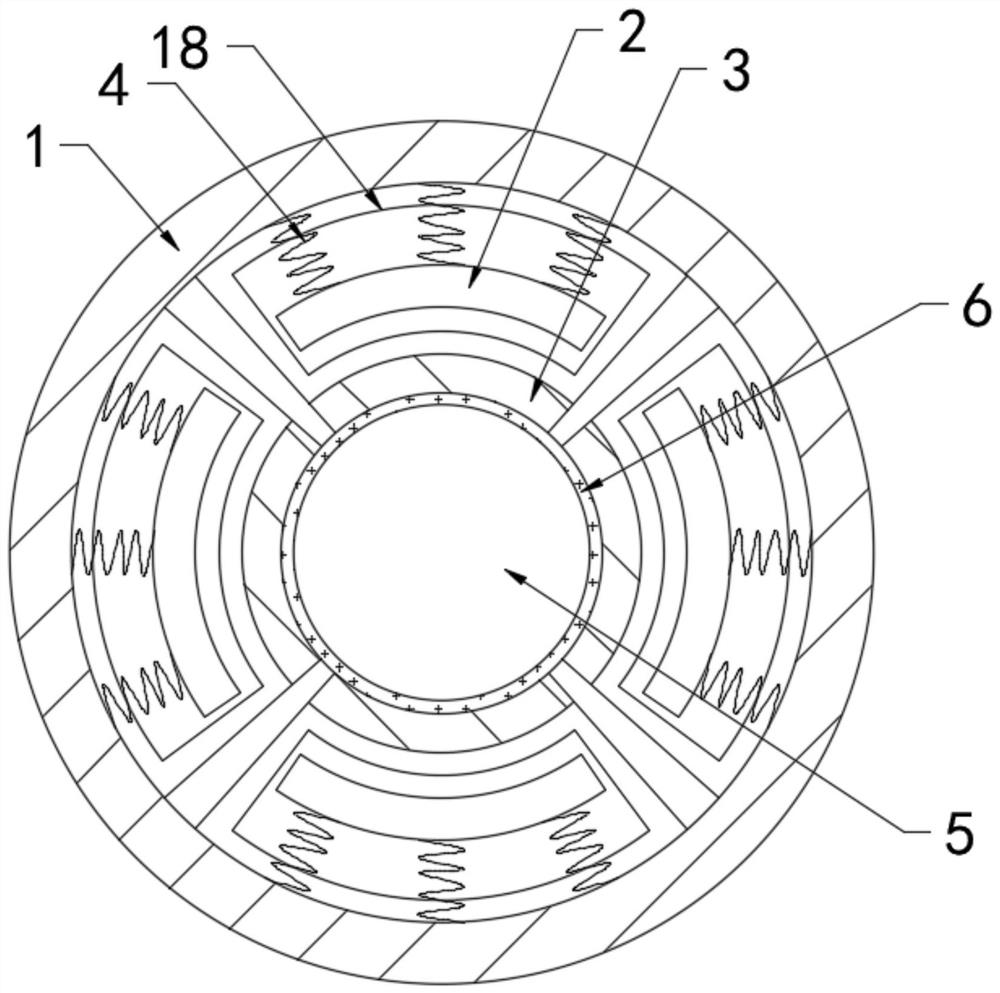

[0044] see Figure 1-11 , the present invention provides a technical solution: a secondary explosion-proof battery steel shell, including an outer shell 1 and a winding core 5, a C-shaped plate 3 is fixedly connected around the inside of the outer shell 1, and the inner side of the C-shaped plate 3 is bonded with a resistance The combustion layer 6, the top and the bottom of the C-shaped plate 3 are all provided with a first chute 18, the first chute 18 is slidably connected with a buffer plate 2, and the buffer plate 2 is provided with a plurality of through holes 31, the outer shell 1 and the buffer A plurality of first springs 4 are fixedly connected between the plates 2, and a plurality of tapered holes 15 are provided on the outer shell 1, and the small ends of the tapered holes 15 face inwards, and the large ends face outwards. The closed ball 17 tangent to the tapered hole 15 is fixedly connected by the fourth spring 16 between the large end of the tapered hole 15 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com