Steel structure health monitoring system and method based on digital twinborn technology

A technology of health monitoring system and steel structure, applied in measurement devices, image data processing, data processing applications, etc., can solve the problems of analysis and prediction deviation, failure to achieve high-quality digital models, etc., to improve reliability and increase damage Identify and expand the effect of connotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

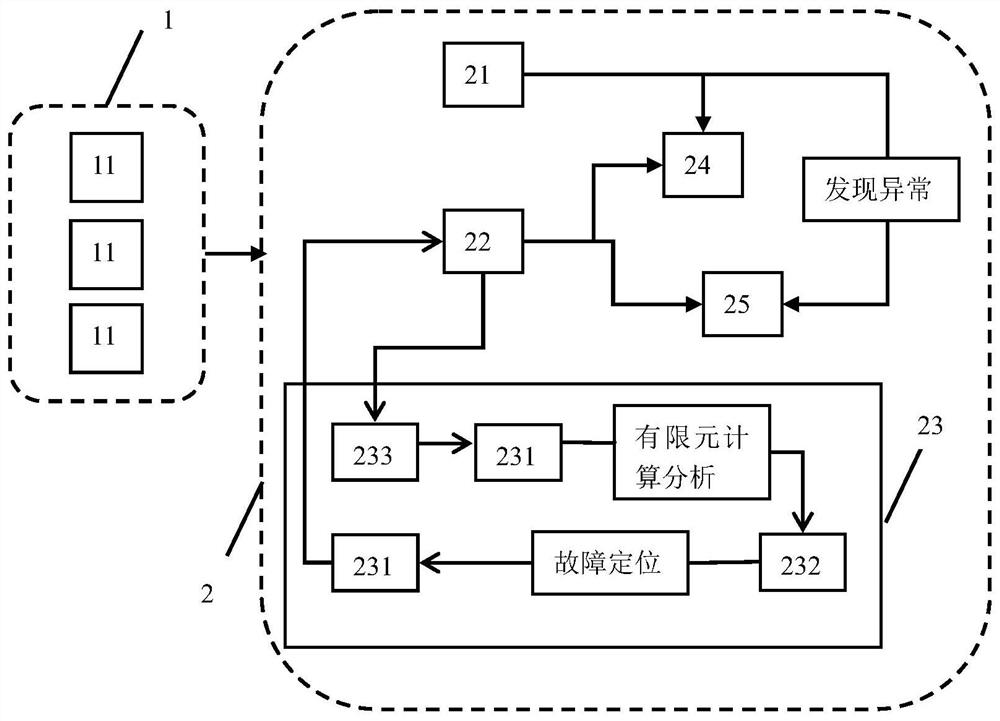

[0029] Embodiment one refers to figure 1, a steel structure health monitoring system and method based on digital twin technology, including a distributed data acquisition system (1), a remote data transmission and control system (2); the remote data transmission and control system (2) includes a local computer system ( 21), remote management and monitoring computer system (22), steel structure safety performance prediction module (23), three-dimensional model and visualization module (24) and alarm module (25); distributed acquisition system (1) includes A number of structural load sensors (11) and environmental monitoring sensors (11) on the structure, the distributed acquisition system (1) performs dynamic online monitoring and acquisition of the data collected by each sensor (11), and uploads the collected data through the 5G network To the remote management and monitoring computer system (22); the local computer system (21) is connected to the network of the remote managem...

Embodiment 2

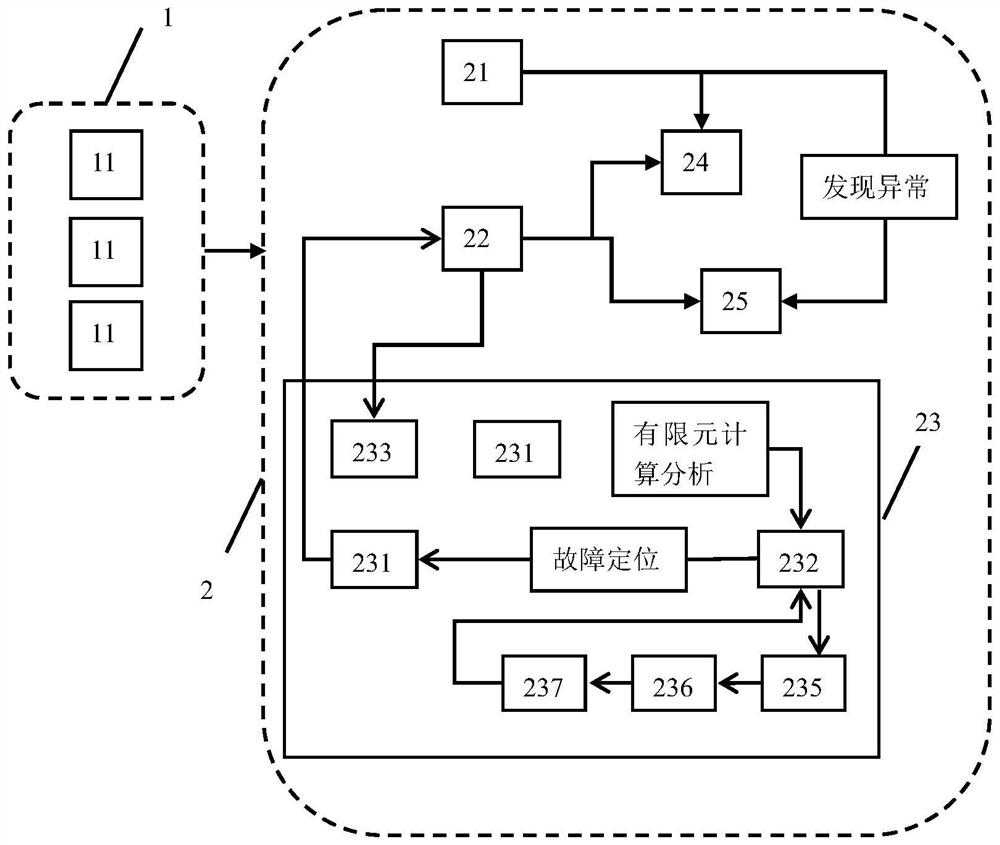

[0031] Embodiment two refers to figure 2 , a steel structure health monitoring system and method based on digital twin technology, the difference from Embodiment 1 is that the finite element simulation analysis model refinement creation method is used, and the steel structure safety performance prediction module (23) also includes complex large-scale Model processing module (235), finite element model correction module (236), experimental model fusion module (237); the initial structural value of the finite element simulation analysis model (232) passes the finite element model correction module (236) and the experimental model fusion module (237) is converted into a fine structure value to obtain a finite element simulation analysis model (232) with a fine structure value. Carry out inversion-based fault location through the damage identification module (234), to accurately predict the structural response and judge the failure, through the analysis and calculation of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com