Radioactive waste liquid evaporator liquid level control system and method

A technology of radioactive waste liquid and liquid level control, applied in the direction of evaporator regulation/control, liquid level control, control/regulation system, etc., can solve the problem of interference, can not provide accurate output immediately, correct time lag, take a long time and other problems, to ensure the purification quality and evaporation efficiency, reduce disturbance, and improve the effect of hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

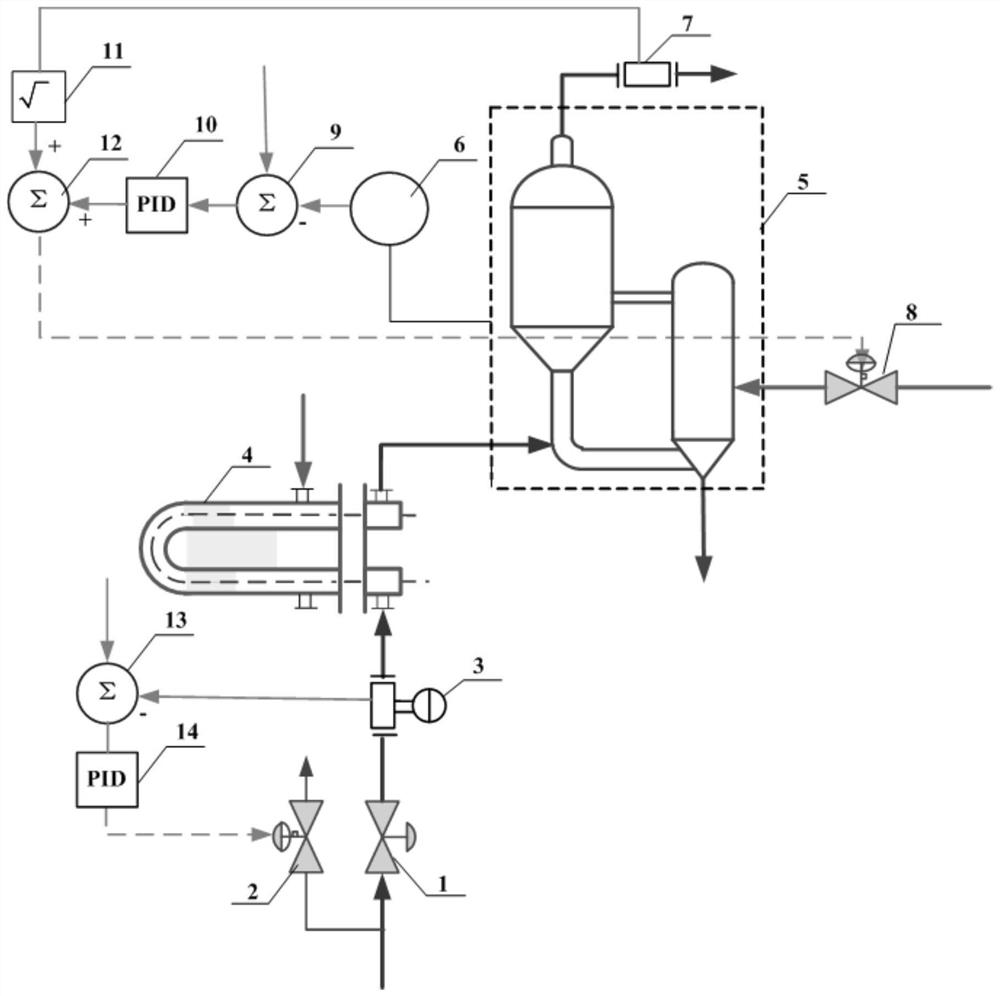

[0051] A liquid level control system for a radioactive waste liquid evaporator, comprising: a liquid level main control loop, a liquid level feedforward control loop, and a feeding flow control loop;

[0052] The feed flow control loop feeds the preheater with a fixed flow rate;

[0053] After the disturbance causes the liquid level in the evaporator to change, the liquid level main control loop adjusts the fixed value flow rate of the preheater and the amount of saturated steam injected into the evaporator to restore the liquid level;

[0054] The liquid level feedforward control loop introduces the secondary steam flow after the gas-liquid separation of the evaporator into the main liquid level control loop as an interference quantity.

[0055] Disturbances that cause changes in the liquid level of the evaporator include: disturbances caused by the control system and disturbances caused by disturbance quantities.

[0056] The disturbances caused by the system include: distu...

Embodiment 2

[0073] This embodiment provides a liquid level control method for a radioactive waste liquid evaporator, which is applied to the liquid level control system for a radioactive waste liquid evaporator in the previous embodiment, and feeds materials at a constant flow rate to the preheater through the feeding flow control loop;

[0074] After the disturbance causes the liquid level in the evaporator to change, adjust the fixed value flow rate of the preheater and the amount of saturated steam injected into the evaporator through the liquid level main control circuit to restore the liquid level;

[0075] The liquid level feedforward control loop introduces the secondary steam flow after the gas-liquid separation of the evaporator into the main liquid level control loop as an interference quantity.

[0076] Process flow of the evaporator: The radioactive waste liquid is sent to the preheater 4 for preheating through the feeding valve 1, and enters the evaporator 5 after reaching the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com