Mining equipment for mining machinery

A technology of mining equipment and machinery, applied in conveyors, earth-moving mining, loading/unloading, etc., can solve the problems of great physical harm to workers, much dust in the well, and more toxic gases, so as to ensure stability and continuity and avoid hazards. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

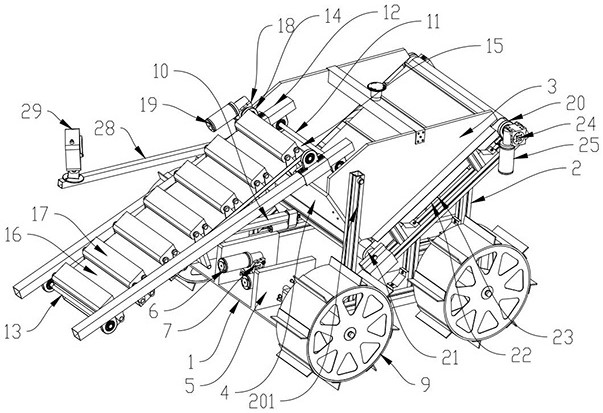

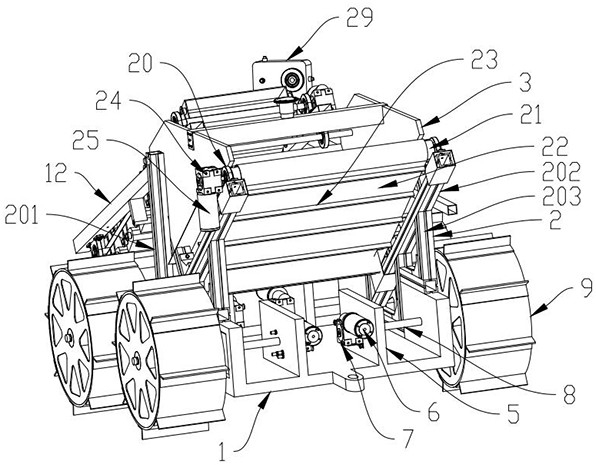

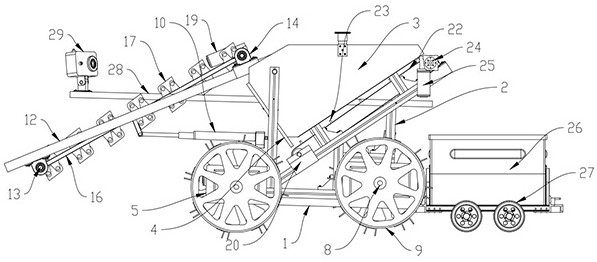

[0020] combined with figure 1 To attach figure 2 , a kind of mining equipment for mining machinery, including a seat plate 1, an automatic moving assembly is installed on the seat plate 1, brackets 2 are installed on both sides of the seat plate 1, side baffles 3 are installed on the brackets 2, two A front baffle 4 is installed between the front ends of the side baffles 3, and an automatic feeding assembly is installed between the front ends of the two side baffles 3 and above the front baffle 4. 3. An automatic unloading assembly is installed at the bottom. The rear end of the seat plate 1 is hinged with a material receiving assembly. The front of the bracket 2 is hinged with an electric push rod 10. The extended end of the electric push rod 10 is hinged with the bottom of the automatic feeding assembly.

[0021] combined with figure 1 And attached fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com