Synchronous pre-pressing reference section bracket construction device and pre-pressing construction method thereof

A technology of construction device and construction method, which is applied in the direction of erecting/assembling bridges, bridge materials, bridges, etc., can solve the problems of sandbags, water bags or reinforcement stacking difficulties, unfavorable environment, water and soil conservation, sand or water waste, etc., to achieve Fast and stable loading and unloading, simple structure and easy operation, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0046] This specific embodiment is only an explanation of the present invention, and is not a limitation of the present invention. Those skilled in the art can make modifications to the present embodiment as required after reading this description, but as long as the claims of the present invention are protected by patent law.

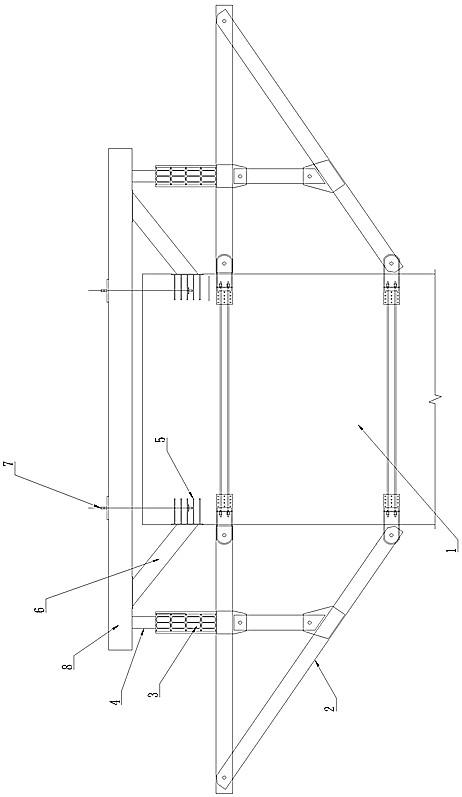

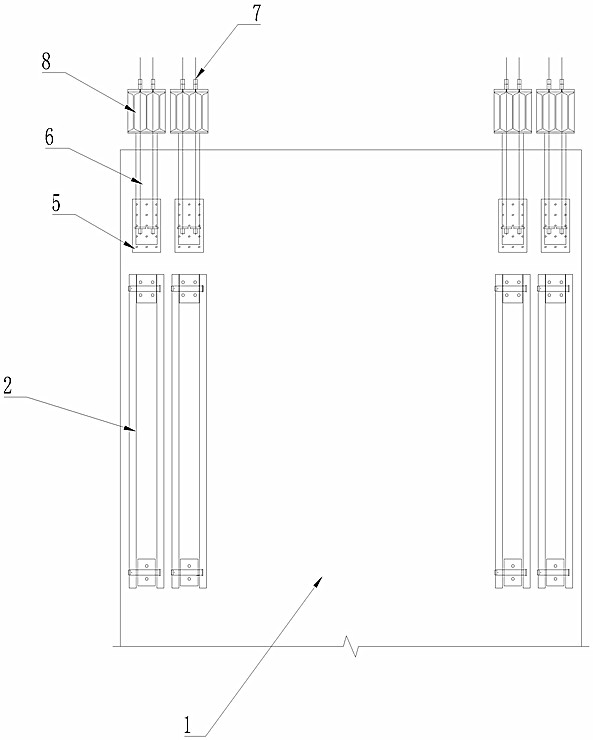

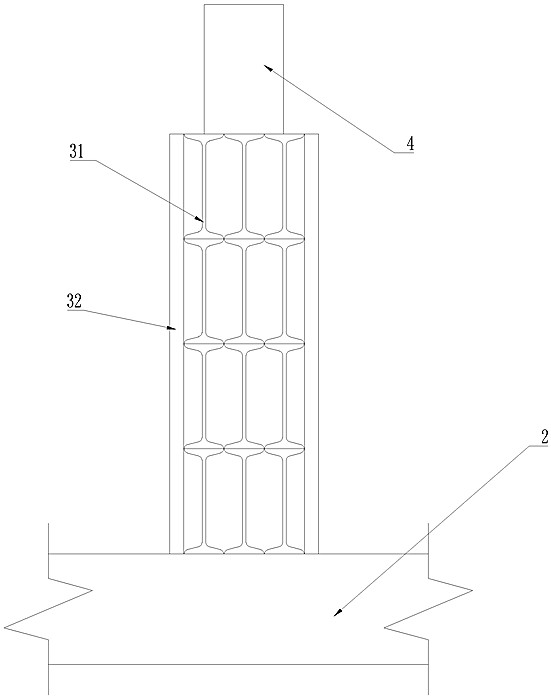

[0047] Such as Figure 1-4As shown: a construction device of the inverted trapezoidal reaction frame jack synchronously preloading the bracket of the base section of the cantilevered beam of the present invention, including a pier column 1, which is characterized in that: the pier column 1 is symmetrically installed with triangles along the bridge to both sides. Bracket 2, the triangular bracket 2 is provided with a compression beam system 3, and the pier column 1 is symmetrically provided with a reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com