An automatic wiring method in yarn weaving process

An automatic threading and yarn technology, which is applied in the field of yarn textile technology, can solve the problems of no follow-up processing, complicated and easy-to-slip operation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

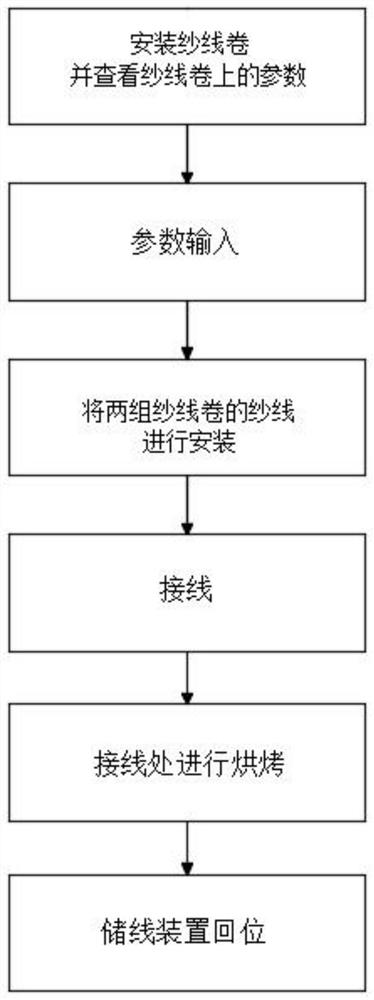

[0027] An automatic wiring method in a yarn weaving process, comprising the steps of:

[0028] S1. Install the yarn roll and check the parameters on the yarn roll. First, install the two sets of yarn rolls on the yarn shaft of the textile equipment respectively, and then check the length of the yarn roll and the tensile strength of the yarn on the yarn roll. ;

[0029] S2, parameter input, input the length of the yarn roll into the meter counter of the splicer, and the output end of the meter counter is electrically connected to the control end of the splicer and the control end of the controller of the wire storage device;

[0030] S3. Install the yarns of the two sets of yarn reels, firstly pass one end of one set of yarns respectively through the splicer, the heater and the storage device and connect them to the textile terminals of the textile equipment;

[0031] S4, wiring, when the length of a group of yarns reaches the length set by the meter counter, the meter counter...

Embodiment 2

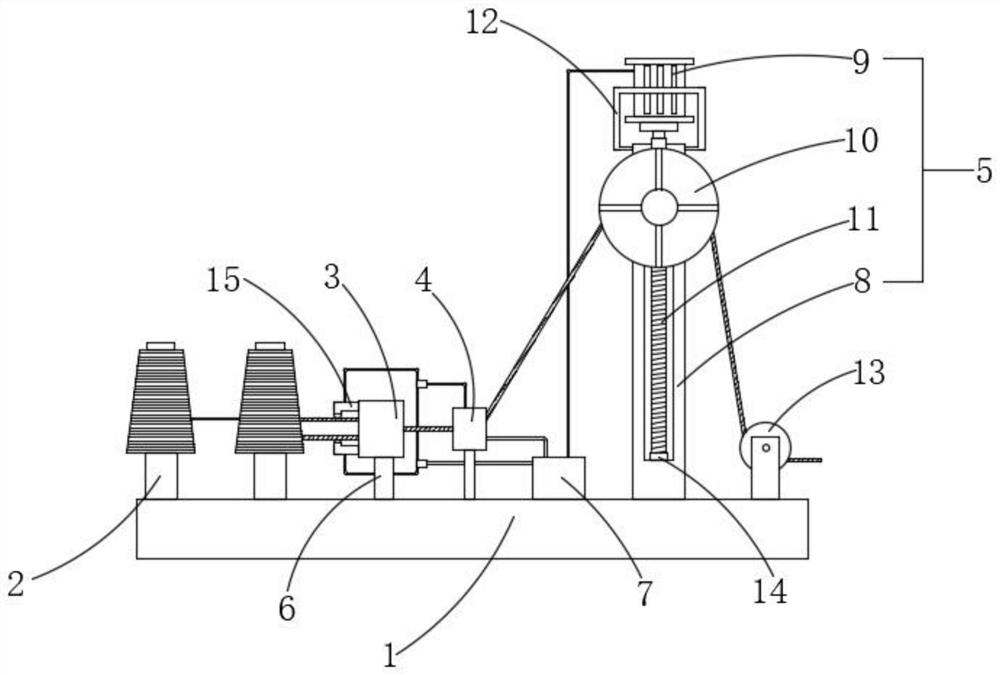

[0038] An automatic threading device for an automatic threading method in the yarn weaving process, comprising a base 1, a splicer 3, a heater 4, a meter counter 15 and a thread storage device 5, the upper end of the base 1 is provided with a The yarn shaft 2 of the coil, the yarn shaft 2 is provided with no less than two groups, the splicer 3 is fixedly installed on the upper end of the base 1 through the support column 6, and the meter counter 15 is fixedly installed on one side of the splicer 3 , and two sets of meter counters 15 are symmetrically arranged, and a motor controller 7 is fixedly installed on the upper end of the base 1 , and the motor controller 7 is electrically connected to the wire storage device 5 .

[0039] The wire storage device 5 includes a column 8, a driving motor 9, a roller 10 and a ball screw 11. The lower end of the column 8 is fixedly welded to the upper end of the base 1, and the column 8 is set as a hollow column, and the ball screw 11 is rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com