Electric reversing control valve for oxygen production and control method

An electric reversing and control valve technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of cumbersome control and complex structure, and achieve the effects of high transmission precision, simple and compact structure, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

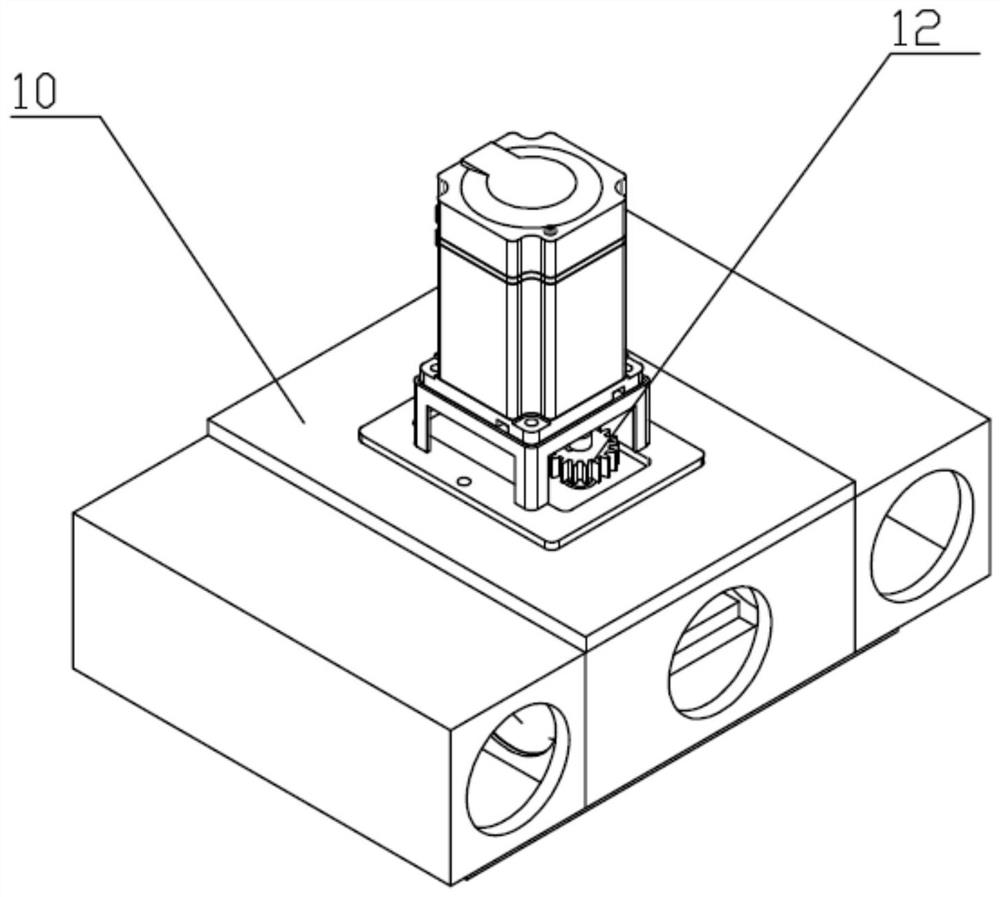

[0045] Such as Figure 1-Figure 6 As shown, the electric reversing control valve for oxygen production includes a valve body 10, a sealing mechanism 11 and a gear drive mechanism 12;

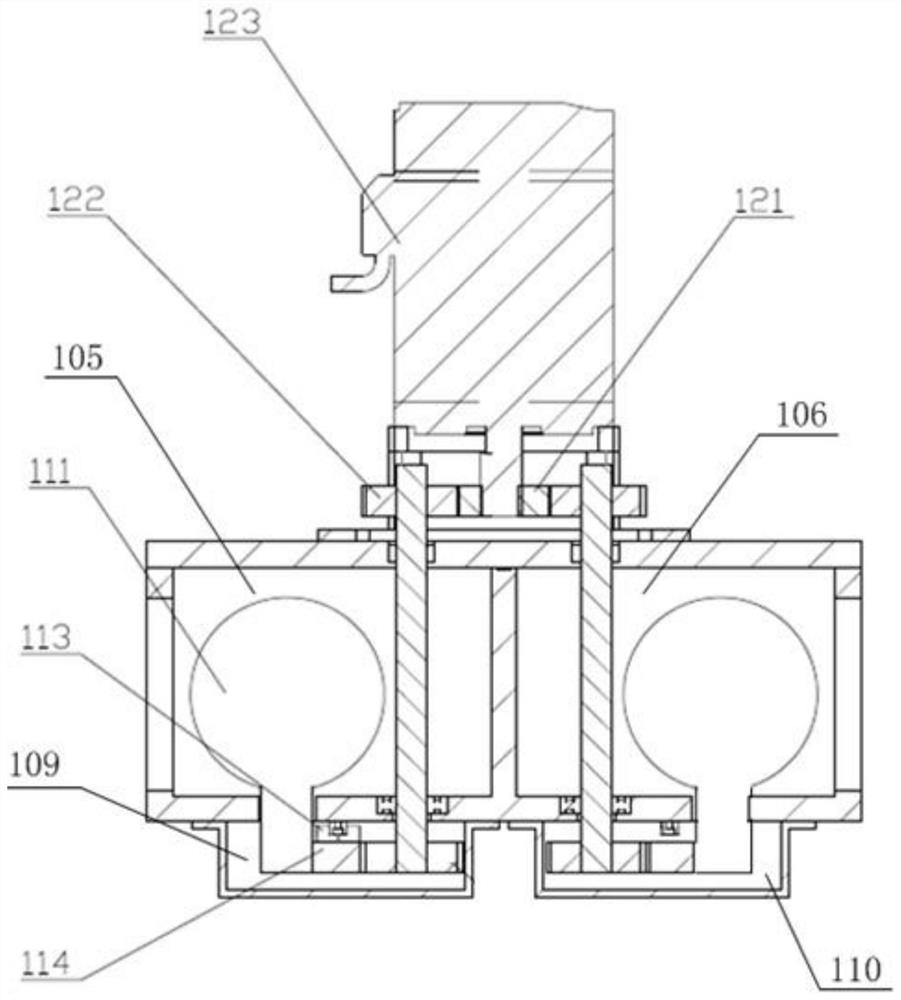

[0046]The valve body 10 is provided with a first public chamber 105, a second public chamber 106, a vacuum chamber 107 and a pressure chamber 108, and the vacuum chamber 107 is connected to the first public chamber 105 and the second public chamber 106 respectively through the first The first communication port and the second communication port communicate, and the pressure chamber 108 communicates with the first common chamber 105 and the second common chamber 106 through the third communication port and the fourth communication port respectively. A gas inlet and outlet 101 is provided, an adsorption tower connection port 102 is provided on the second public chamber 106, a fan inlet connection port 103 is provided on the vacuum chamber 107, and a fan outlet connection port is provided on the pr...

Embodiment 2

[0057] Such as Figure 1-Figure 6 Shown, this embodiment is based on embodiment 1,

[0058] In this embodiment, the first common cavity 105 and the second common cavity 106 are arranged symmetrically, and the vacuum cavity 107 and the pressure cavity 108 are arranged in parallel between the first common cavity 105 and the second common cavity 106, so The two ends of the vacuum chamber 107 communicate with the first public chamber 105 and the second public chamber 106 respectively through the first communication port and the second communication port, and the two ends of the pressure chamber 108 communicate with each other through the third communication port and the fourth communication port respectively. The port communicates with the first common chamber 105 and the second common chamber 106; the bottoms of the vacuum chamber 107 and the pressure chamber 108 are respectively provided with a first installation chamber 109 and a second installation chamber 110, and the first i...

Embodiment 3

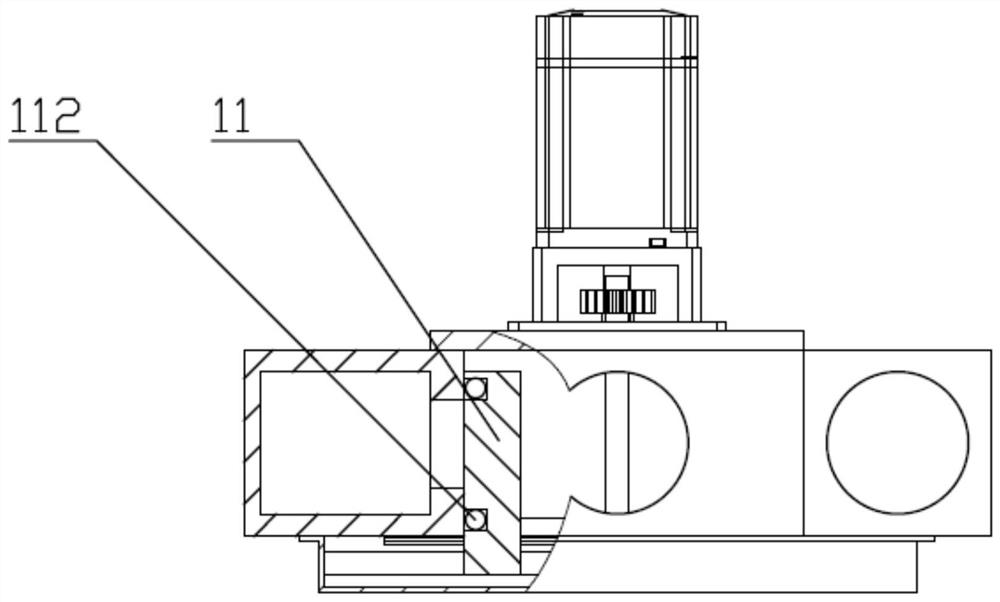

[0061] Such as Figure 1-Figure 6 As shown, this embodiment is based on Embodiment 1 or Embodiment 2, a seal ring 112 is provided on the side wall of the seal seat 111; a position detection sensor 115 is installed on the seal seat 111, and the position detection sensor 115 is connected to the A controller for driving the gear drive mechanism 12 is electrically connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com