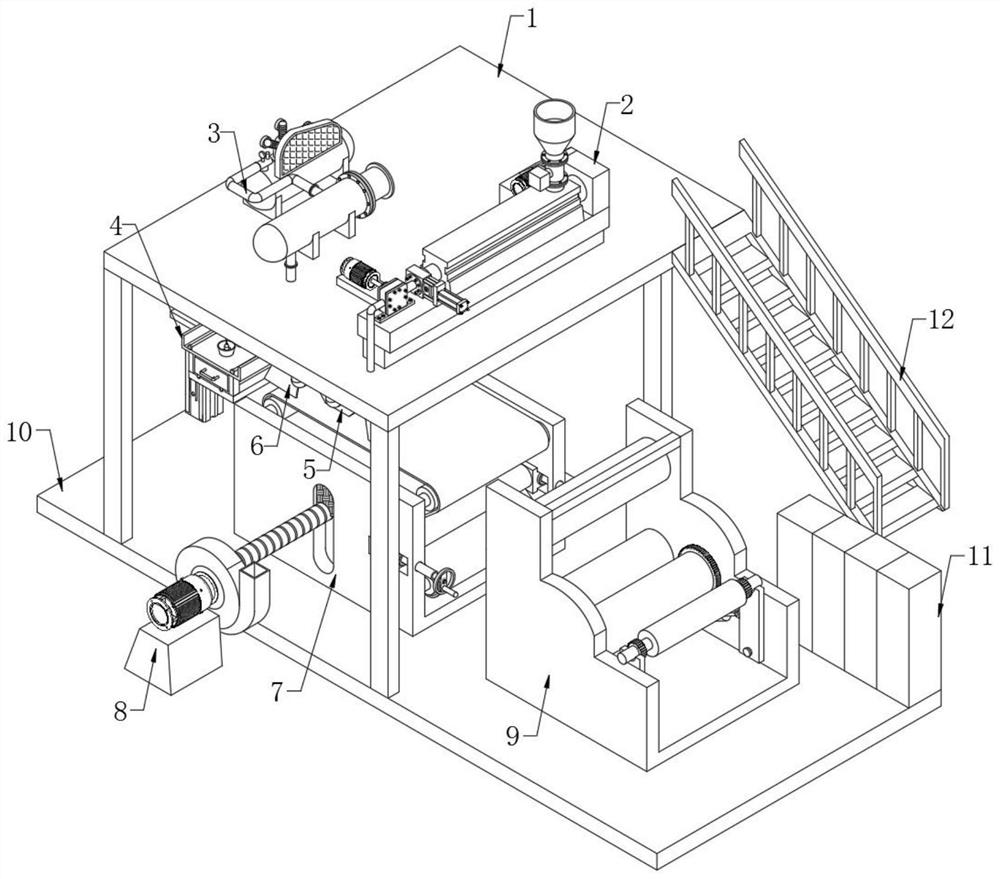

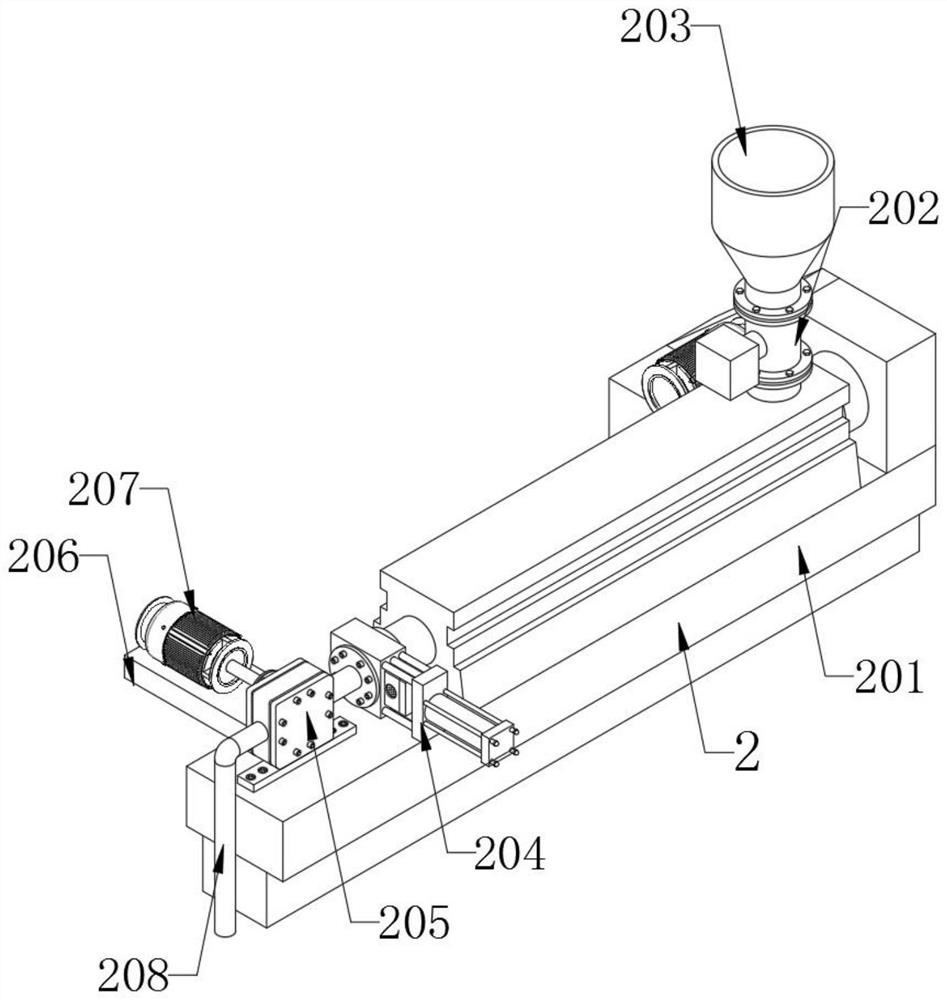

Production system and production method of high-air-permeability composite non-woven fabric

A production system and production method technology, applied in non-woven fabrics, textiles and papermaking, spinneret assemblies, etc., can solve problems such as clogging of spinneret holes, affecting quality, fiber force bonding, etc., and achieve gram weight distribution. The effect of uniform, uniform distribution and uniform spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

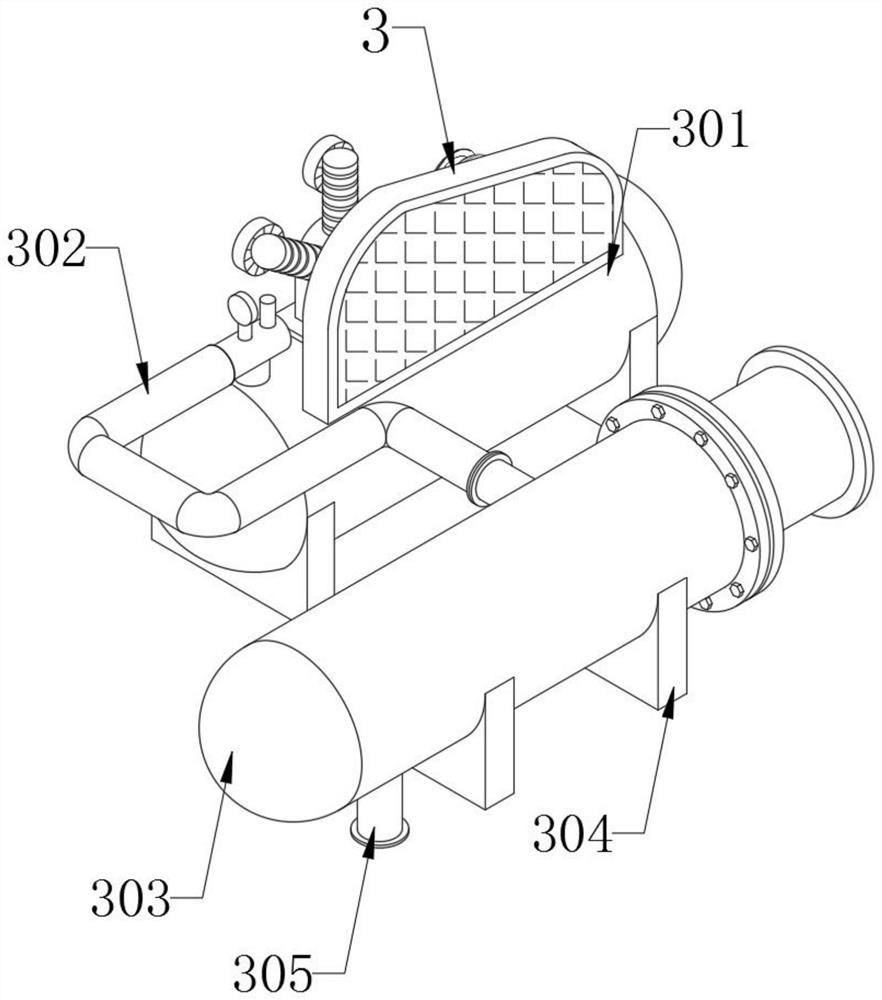

[0034] As a specific embodiment of the present invention, the air supply mechanism 3 includes an air compressor 301, the air outlet of the air compressor 301 is fixedly communicated with one end of the air delivery pipe 302, and the other end of the air delivery pipe 302 is connected with the inlet end of the air heater 303. Fixed communication, the middle part of the bottom end of the air heater 303 is fixedly provided with two support blocks 304, and one side of the bottom end of the air heater 303 is fixedly provided with an air delivery port 305, and one end of the air delivery port 305 is fixedly communicated with one end of the air guide tube, One end of the air duct is fixedly communicated with one end of the tap tube, and multiple tap ends of the tap tube are fixedly communicated with a plurality of vents 502 respectively.

[0035] As a specific embodiment of the present invention, the receiving mechanism 7 includes a receiving frame 701, and the four corners on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com