Wool-like yarn and processing technology and device

A wool yarn and processing device technology, which is applied in the directions of yarn, spinning machine, continuous winding spinning machine, etc., can solve the problem of inconvenient detection of broken threads in the processing of imitation wool yarn, poor three-dimensional feeling of imitation wool yarn, Unfavorable factory production situation and other problems, to achieve the effect of improving the effect of sanding treatment, low cost, and enhancing the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of wool-like yarn, the wool-like yarn is made of FDY polyester filament and polyester DTY by blending, the weight content of FDY polyester filament accounts for 70%, and the weight content of polyester DTY accounts for 30%.

[0046] A kind of processing technology of wool-like yarn, concrete steps are as follows:

[0047] Step 1, the imitation wool yarn is processed through the upper yarn structure of the two-for-one twister;

[0048] Step 2, the sanding structure of the two-for-one twister performs multi-directional sanding treatment on the imitation wool yarn;

[0049] Step 3: after the wool-like yarn is sanded, the tension-guiding treatment is carried out through the tension structure of the two-for-one twister, and then the winding treatment is carried out to obtain the wool-like yarn.

Embodiment 2

[0051] Embodiment 2 is a further improvement to Embodiment 1, a kind of wool-like yarn, the wool-like yarn is formed by blending FDY polyester filament and polyester DTY, the weight content of FDY polyester filament accounts for 50%, and the weight of polyester DTY The content accounts for 50%.

[0052] A kind of processing technology of wool-like yarn, concrete steps are as follows:

[0053] Step 1, the imitation wool yarn is processed through the upper yarn structure of the two-for-one twister;

[0054] Step 2, the sanding structure of the two-for-one twister performs multi-directional sanding treatment on the imitation wool yarn;

[0055] Step 3: after the wool-like yarn is sanded, the tension-guiding treatment is carried out through the tension structure of the two-for-one twister, and then the winding treatment is carried out to obtain the wool-like yarn.

[0056] The wool-like yarn is made of FDY polyester filament and polyester DTY by blending. The wool-like yarn not ...

Embodiment 3

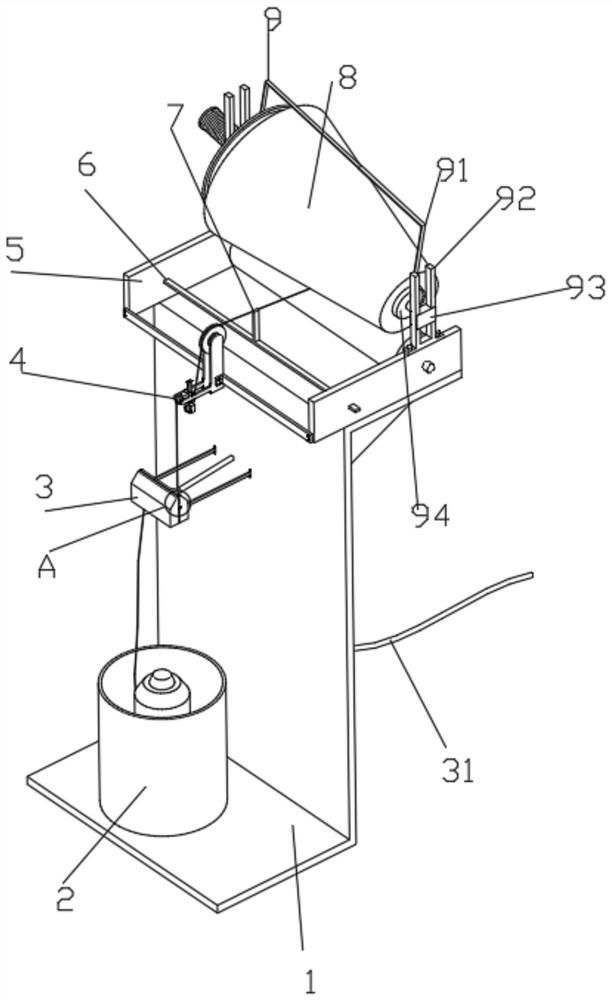

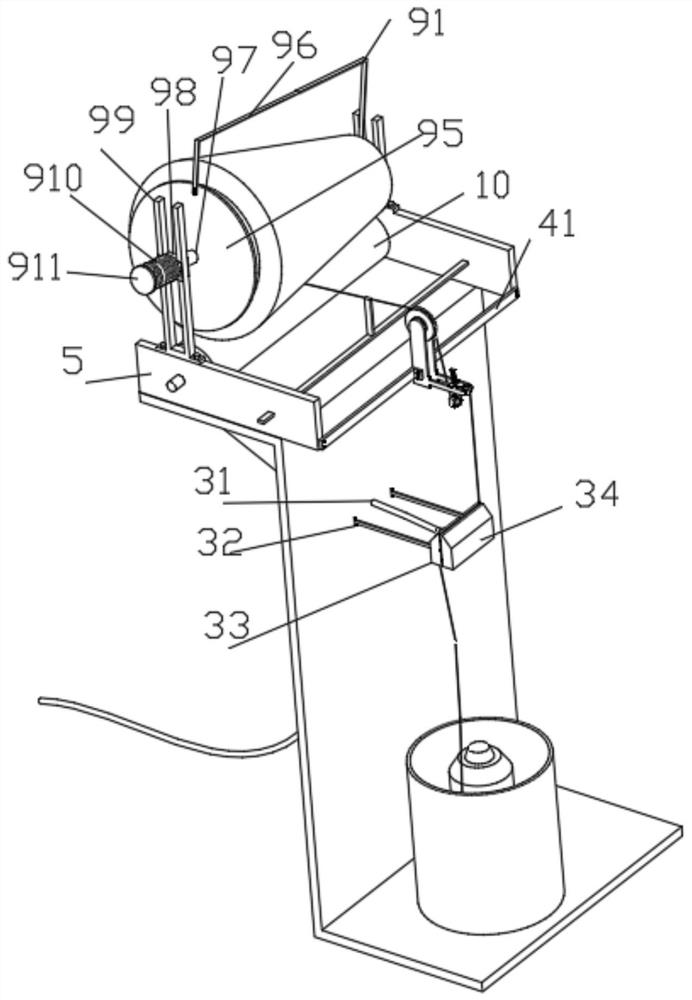

[0058] Embodiment 3 is a further improvement to Embodiment 1, such as figure 1 , 2 , 3, 4, and 5, a processing device for imitating wool yarn processing technology, including a Z-shaped support plate 1, an upper line structure 2, a horizontal slide plate 6, a guide plate 7, a winding roller 8, a driving roller 10 and The driving shaft 11 is fixedly connected with the upper line structure 2 at the top of the lower lateral portion of the Z-shaped support plate 1, and the upper line structure 2 is provided with a yarn volume;

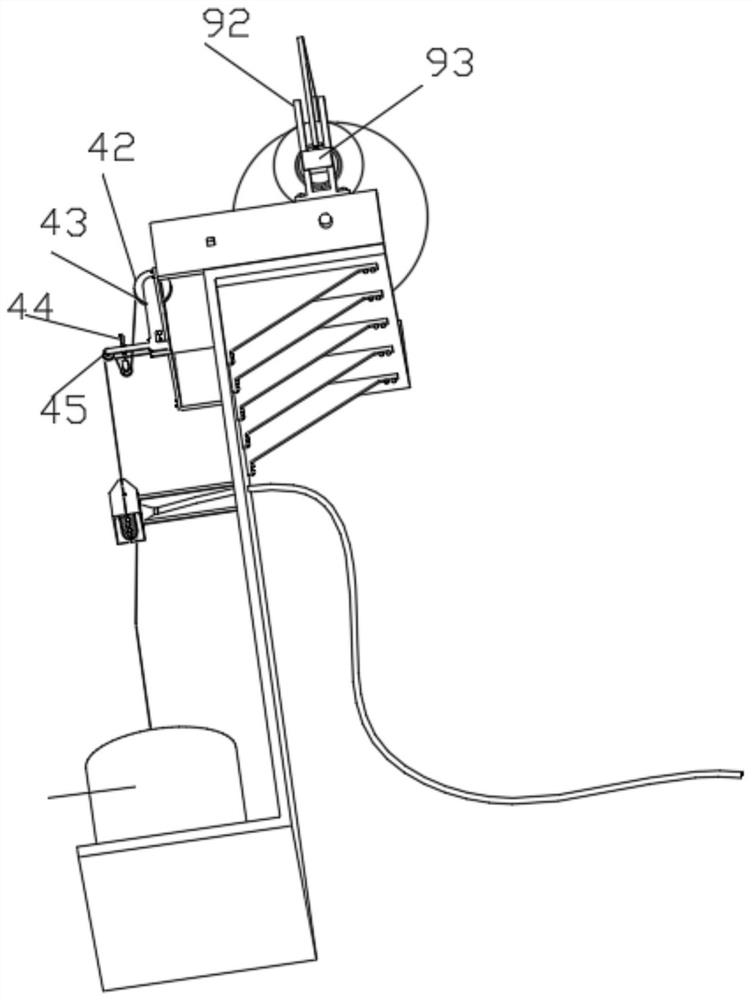

[0059] Such as figure 1 , 2 , 4, 8, and 9, the side wall of the upright part of the Z-shaped support plate 1 is connected with a sanding structure 3 for multi-directional sanding of the imitation wool yarn, and the sanding structure 3 can be opened conveniently to realize the wool-like yarn Wear in the sanding structure 3, the sanding structure 3 includes a dust removal pipe 31, a horizontal plate 32, a first dust collection cover 33, a second dust coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com