Artificial intelligence control system and method for reducing foam of coal gas industrial wastewater

A technology of artificial intelligence and industrial wastewater, applied in the direction of water treatment parameter control, biological treatment adjustment methods, chemical instruments and methods, etc., can solve the problems of consumption and foam production reduction, and achieve the effect of low operating cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

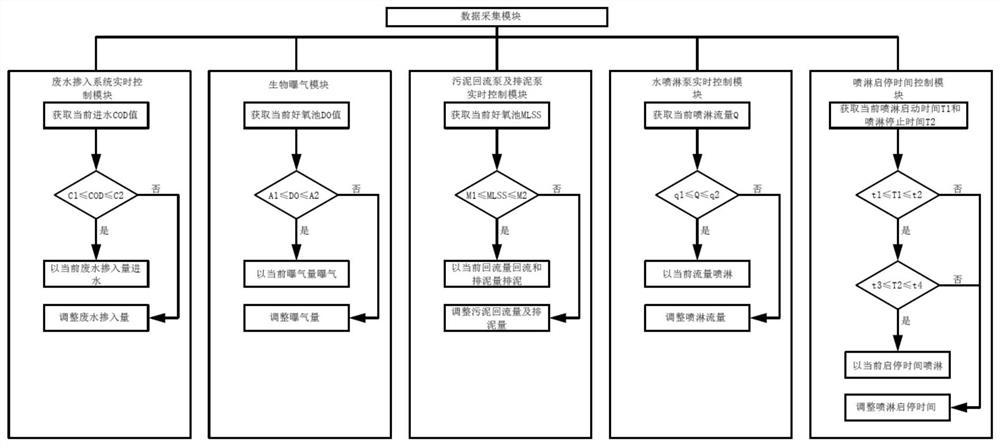

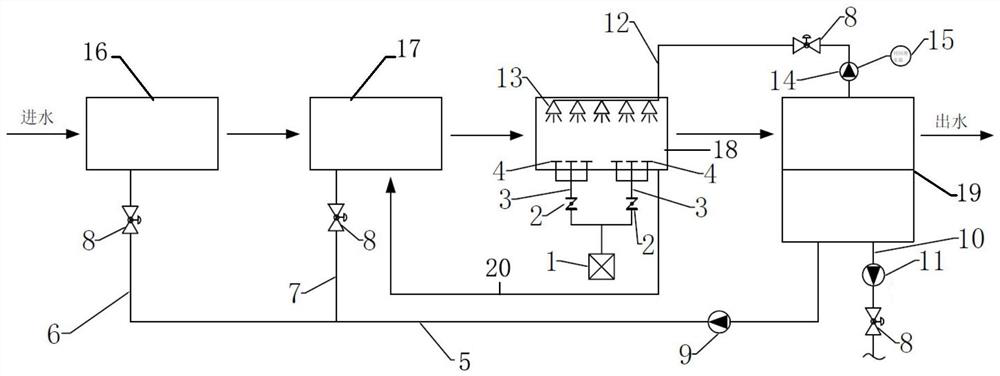

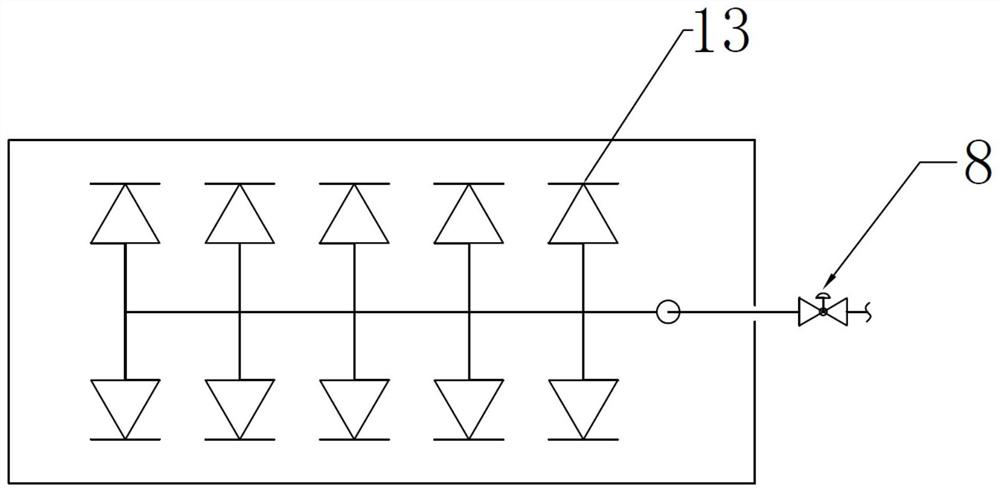

[0041] Embodiment 1 of the present application provides an artificial intelligence control system for reducing foam in coal-to-gas industrial wastewater, which is used in a sewage treatment plant based on the AAO process, including anaerobic pool 16, anoxic pool 17, aerobic pool 18, Mud water separation pool 19 and artificial intelligence control system. The anaerobic pool 16, the anoxic pool 17, the aerobic pool 18, and the mud-water separation pool 19 can be conventionally arranged and connected in sequence. The artificial intelligence control system includes a data acquisition module, a real-time control module of the wastewater mixing system, a biological aeration module, a real-time control module of the sludge return pump and a sludge discharge pump, a real-time control module of the water spray pump, and a spray start-stop time control module. module.

[0042] The data acquisition module includes an influent flowmeter, a pH monitoring device, a temperature monitoring d...

Embodiment 2

[0050] Embodiment 2 of the present application provides a control method of an artificial intelligence control system for reducing foam in coal-to-gas industrial wastewater, comprising the following steps:

[0051] S1. In the pretreatment process before the biochemical treatment (before the anaerobic tank), the wastewater is first adjusted by dosing, so that the pH value of the biochemical system influent is 6.5-8.5, and the temperature is controlled at 20°C-40°C.

[0052] S2. The waste water passes through the anaerobic pool, the anoxic pool, the aerobic pool and the mud-water separation pool in turn; the nitrifying liquid in the aerobic pool flows back to the anoxic pool through the nitrifying liquid return pipe; Aeration; the sludge at the bottom of the mud-water separation tank is returned to the anaerobic tank and the anoxic tank through the sludge return pipe, and the remaining sludge in the mud-water separation tank is discharged through the sludge discharge pipe; the su...

Embodiment 3

[0060] Embodiment 3 of the present application provides an artificial intelligence control method for reducing foam in coal-to-gas industrial wastewater, comprising the following steps:

[0061] S1. In the pretreatment process before the biochemical treatment, the wastewater is firstly adjusted by dosing, so that the pH value of the biochemical system influent is 7.0, and the temperature is controlled at 35°C.

[0062] S2. The waste water passes through the anaerobic pool, the anoxic pool, the aerobic pool and the mud-water separation pool in turn; the nitrifying liquid in the aerobic pool flows back to the anoxic pool through the nitrifying liquid return pipe; Aeration; the sludge at the bottom of the mud-water separation tank is returned to the anaerobic tank and the anoxic tank through the sludge return pipe, and the remaining sludge in the mud-water separation tank is discharged through the sludge discharge pipe; the supernatant of the mud-water separation tank is used to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com