Rotational molding device and process for children's slide part

A technology for slides and components, which is applied in the field of rotomolding devices for children's slide parts, which can solve problems such as reduced service life of slides, slide damage, and children's hazards, and achieve the effects of eliminating internal stress, uniform force, and rapid cooling and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A rolling molding device for children's slide parts and its process, the process includes the following steps:

[0032] S1 Feeding: Pour dry powder raw materials such as PVC paste resin into the heating mold, and use a roller to evenly distribute it on the surface of the heating mold;

[0033] S2 heating: power on the heating mold, the heating mold heats the dry powder raw materials such as PVC paste resin, and the roller rolls the materials in turn during the heating process, so that the softened PVC paste resin and other dry powder raw materials are quickly combined together ;

[0034] S3 mold closing: attach the slide mold to the bottom plate after the initial shaping;

[0035] S4 Feeding: Pour dry powder raw materials such as PVC paste resin into the heating mold, the raw materials cover the surface of the slide forming mold, and use a roller to evenly distribute it on the surface of the slide mold;

[0036] S5 Heating: Heating the slide mold and the heating mold,...

Embodiment 2

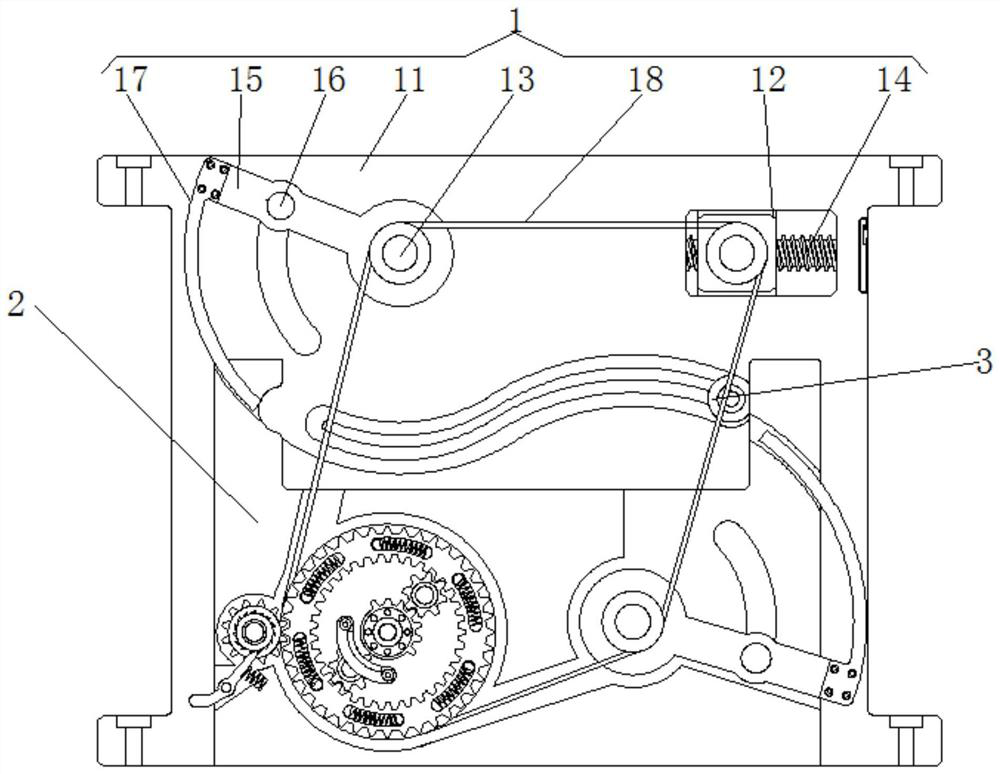

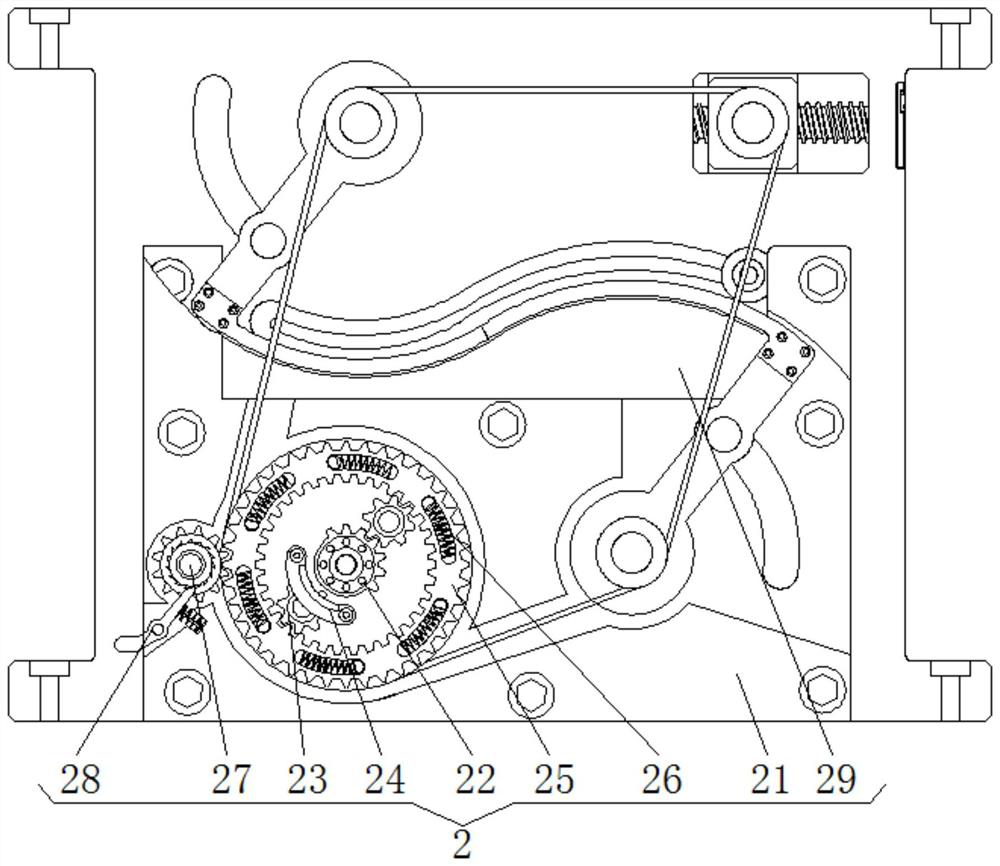

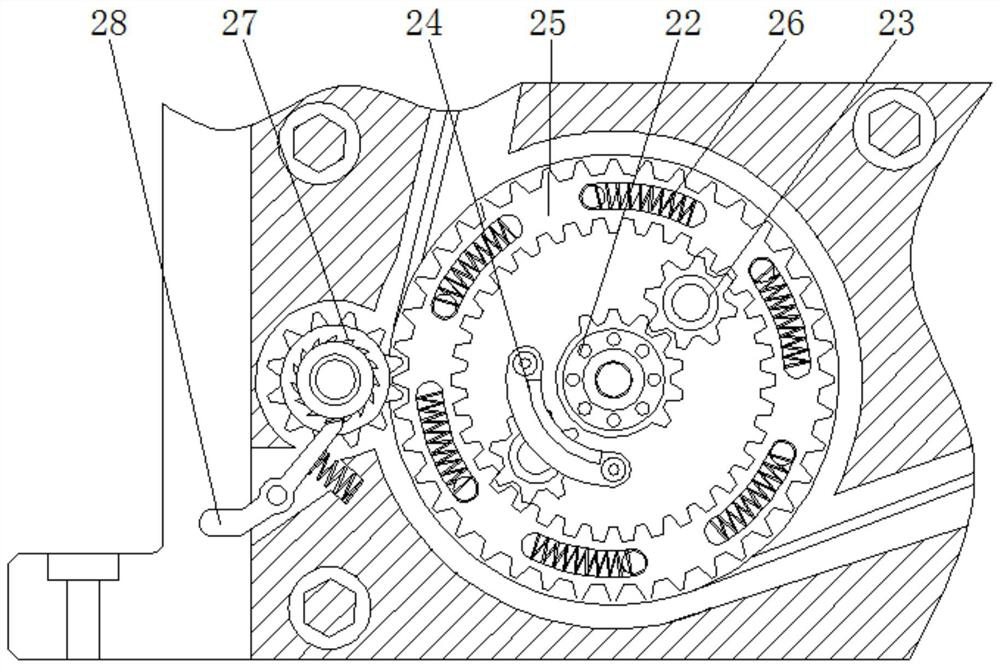

[0039] see Figure 1-7, a rolling molding device for children's slide parts and its process, including a mold mechanism 1, the mold mechanism 1 includes a frame 11, the inside of the frame 11 is slidingly connected with an adjustment slider 12, and the adjustment slider 12 is connected with a timing belt Wheel 13, the internal rotation of the adjustment slider 12 is connected with an adjustment screw 14, how to rotate the frame 11 is connected with a mold clamping rocker 15, the back of the mold clamping rocker 15 is fixedly connected with a positioning slide bar 16, and the mold clamping rocker 15 The outer side of the synchronous pulley 13 is fixedly connected with a decomposition mold 17, and the outer transmission of the synchronous pulley 13 is connected with a synchronous belt 18. With the mutual cooperation of the two sets of disassembly molds 17, a complete internal cavity of the curved slide can be formed. After the mold drawing is completed , forming a complete arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com