Electrically-assisted double-face plate face-to-face grinding device

An electrical auxiliary, plate technology, used in positioning devices, feeding devices, clamping and other directions, can solve the problems of poor service environment of engineering materials, affecting forming quality, denting, bending, etc., to avoid single-sided deformation and achieve good forming. The effect of quality and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is described in further detail:

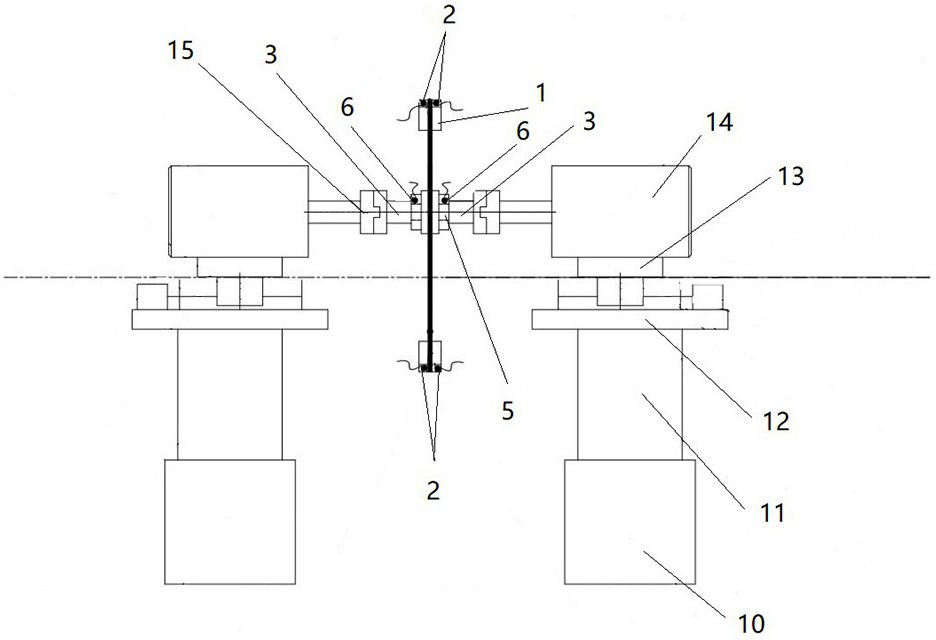

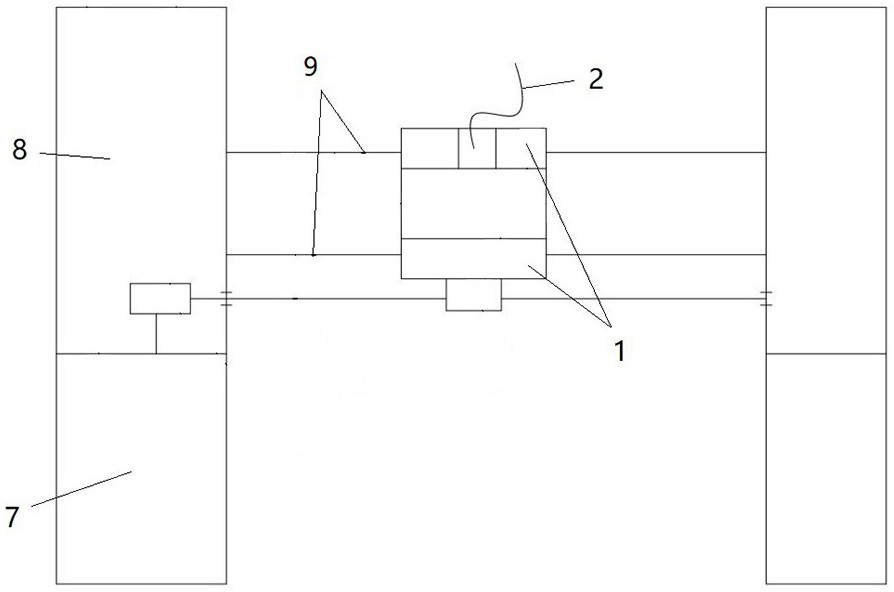

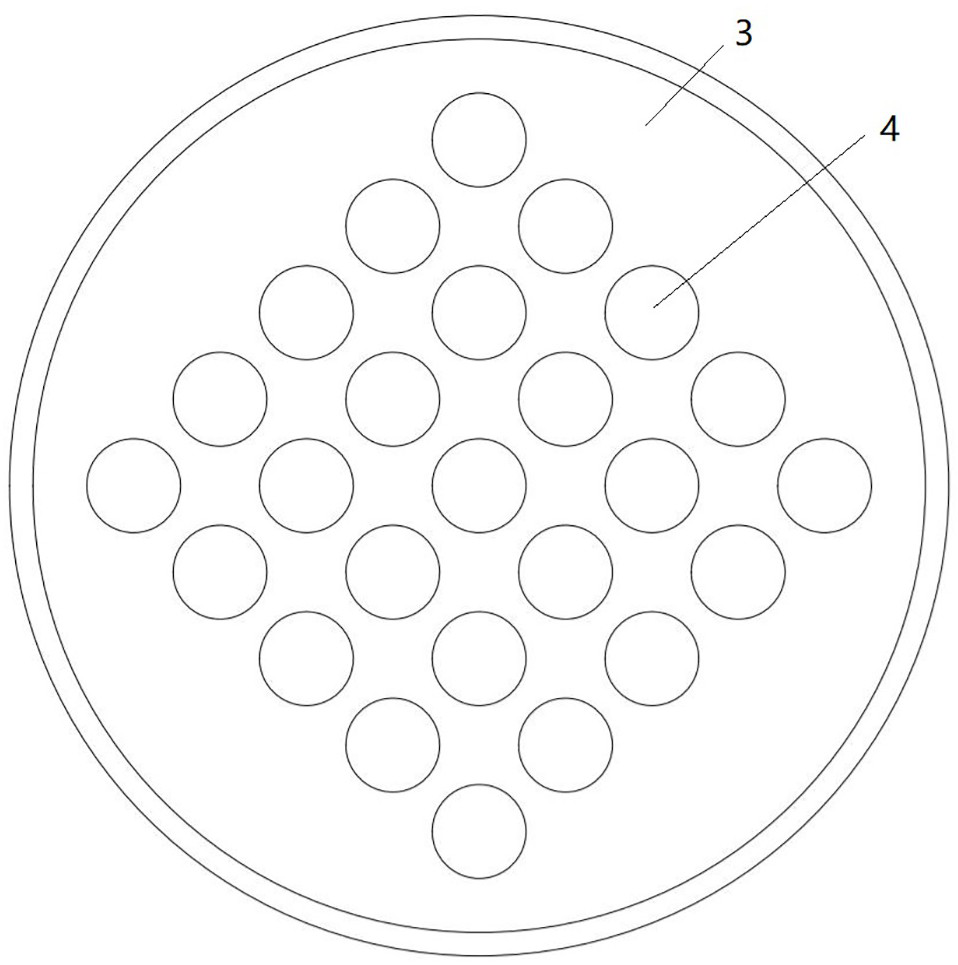

[0025] like figure 1 As shown in the figure, an electric-assisted double-face plate rolling device includes a clamping device for clamping the plate and two sets of plate processing devices symmetrically arranged on both sides of the clamping device, and two sets of plate processing devices are arranged symmetrically on the left and right It can realize the surface gradient deformation of both sides of the sheet, and ensure good sheet forming quality, avoid single-sided deformation, resulting in poor deformation quality of the sheet, and make the surface nano-layer thicker, improve and enhance the fatigue strength of the material, resistance Corrosion and wear resistance, etc.; the clamping device includes two concave clamps 1 up and down, and the left and right sides of the two clamps 1 are provided with first electrical auxiliary joints 2 .

[0026] The plate processing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com