Material box cleaning equipment for food safety production

A technology for cleaning equipment and food safety, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effect of increasing the stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

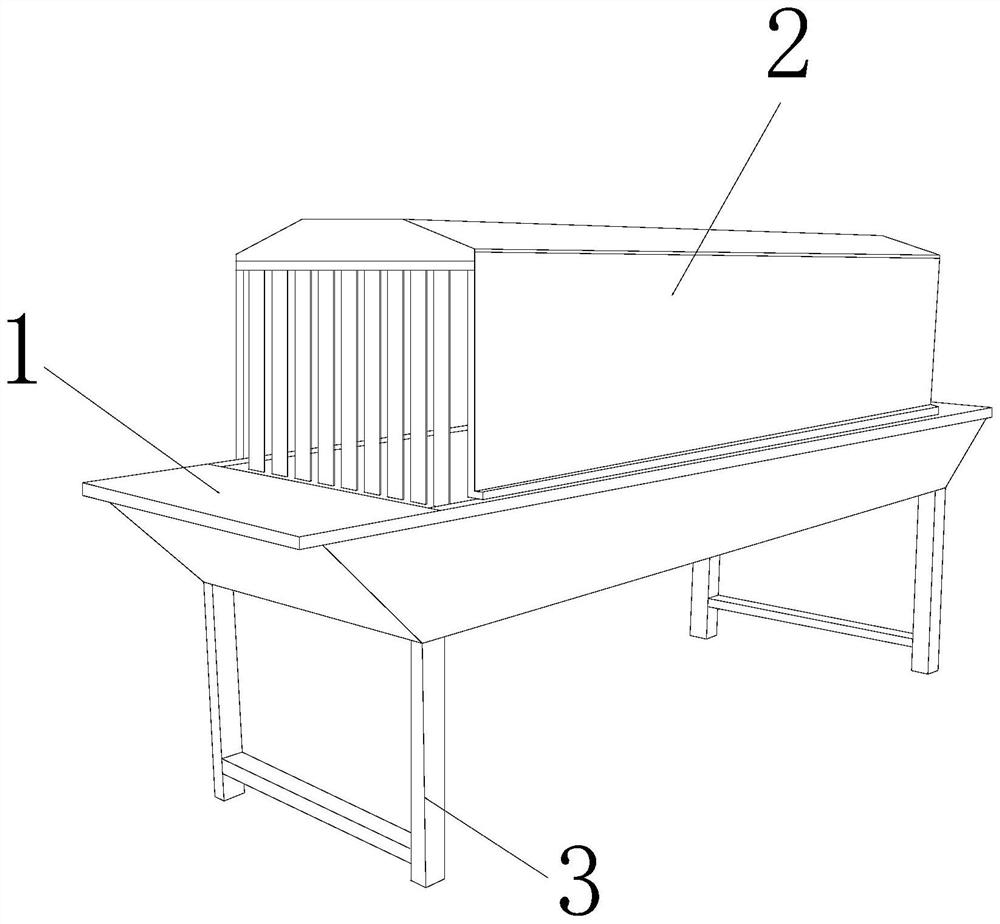

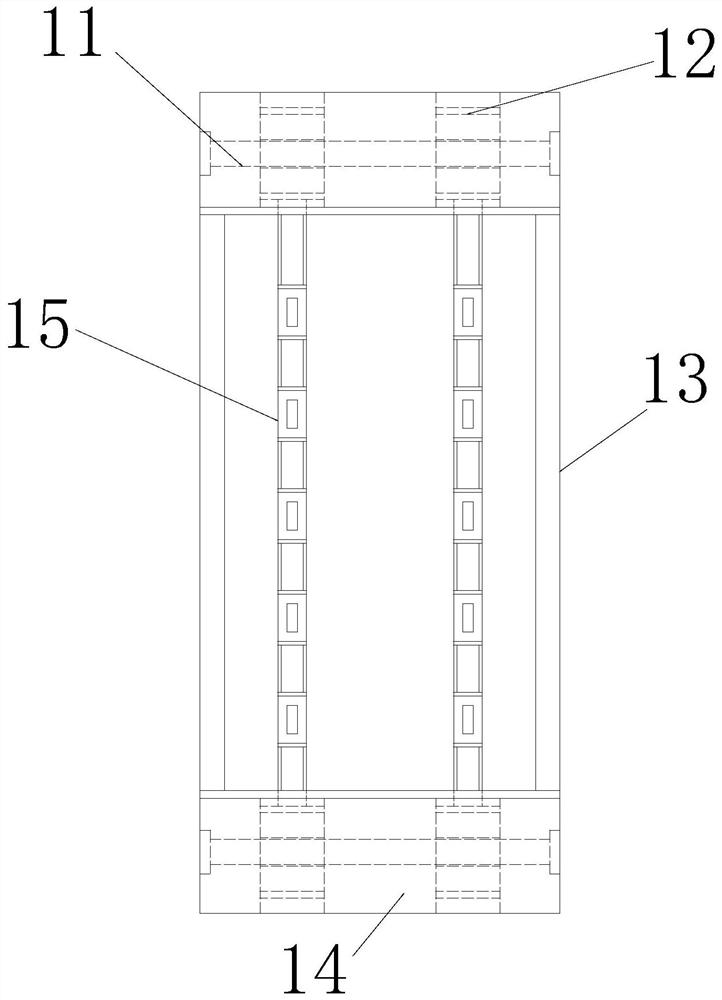

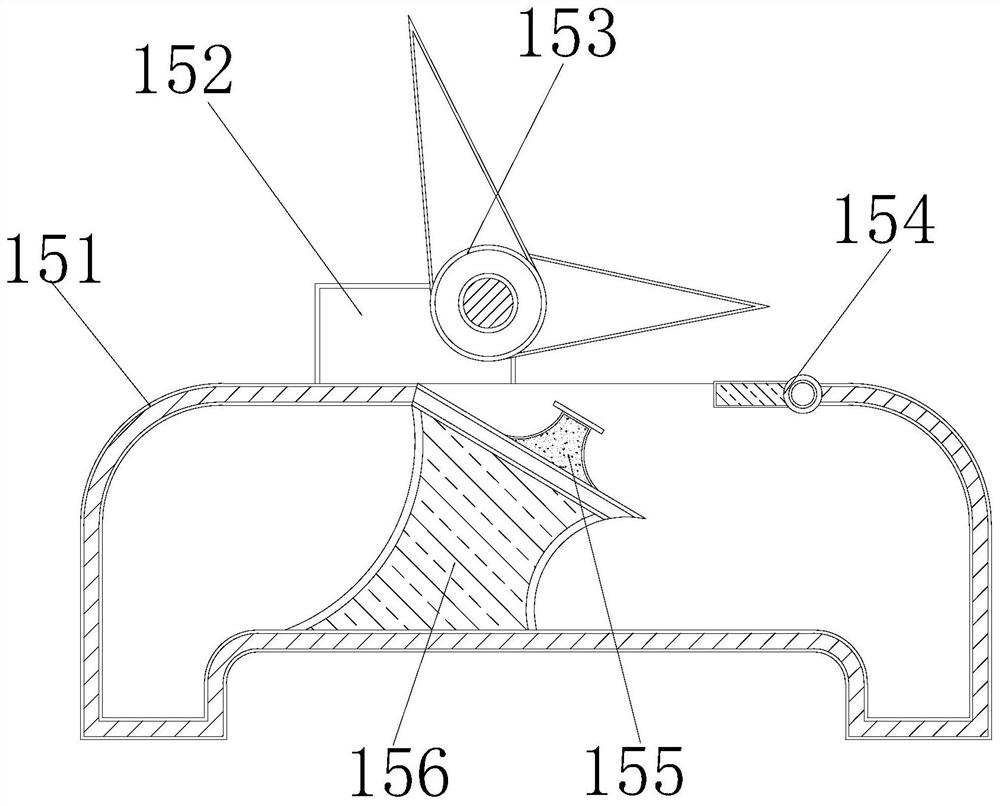

[0030] as attached figure 1 to attach Figure 6 Shown:

[0031] The present invention provides a material box cleaning equipment for food safety production, the structure of which includes a transmission device 1, a cleaning box 2, and a support rod 3, the upper end of the transmission device 1 is welded to the lower end of the cleaning box 2, and the support rod 3 The upper end is welded to the lower end of the transmission device 1. The transmission device 1 includes a mounting rod 11, a transmission plate 12, a mounting plate 13, a storage plate 14, and a transmission chain plate 15. The outside of the installation rod 11 is movably engaged with the inside of the transmission plate 12. The outer sides of both ends of the installation rod 11 are embedded and connected with the inner side of the storage plate 14, the inner side of the transmission plate 12 is movably engaged with the outer side of the transmission chain plate 15, and the outer side of the installation plate...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

[0040] The present invention provides a bin cleaning device for food safety production. The auxiliary plate 531 includes a reinforcement plate 311, an anti-skid plate 312, and a pressure block 313. The right end of the reinforcement plate 311 is embedded and connected to the left end of the anti-skid plate 312. The left end of the pressure block 313 is vertically installed on the right end of the reinforcement plate 311. There are two anti-skid plates 312, distributed and installed on both sides of the pressure block 313, and made of rough plastic material, so that the auxiliary plate 531 can rotate At this time, the friction force with the material frame is increased through the material and quantity properties of the anti-skid plate 312, so as to play an anti-skid effect.

[0041] Wherein, the pressure block 313 includes a pressure receiving plate 131, a connecting block 132, an embedding plate 133, and a pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com