Breathable elastic composite non-woven fabric and manufacturing method thereof

A manufacturing method and technology of non-woven fabrics, which are applied in medical science, clothing, underwear, etc., can solve the problems of poor air permeability of elastic films, difficult heat emission, easy breeding of bacteria, etc., achieve soft touch, improve wearing comfort, reduce The effect of the risk of tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

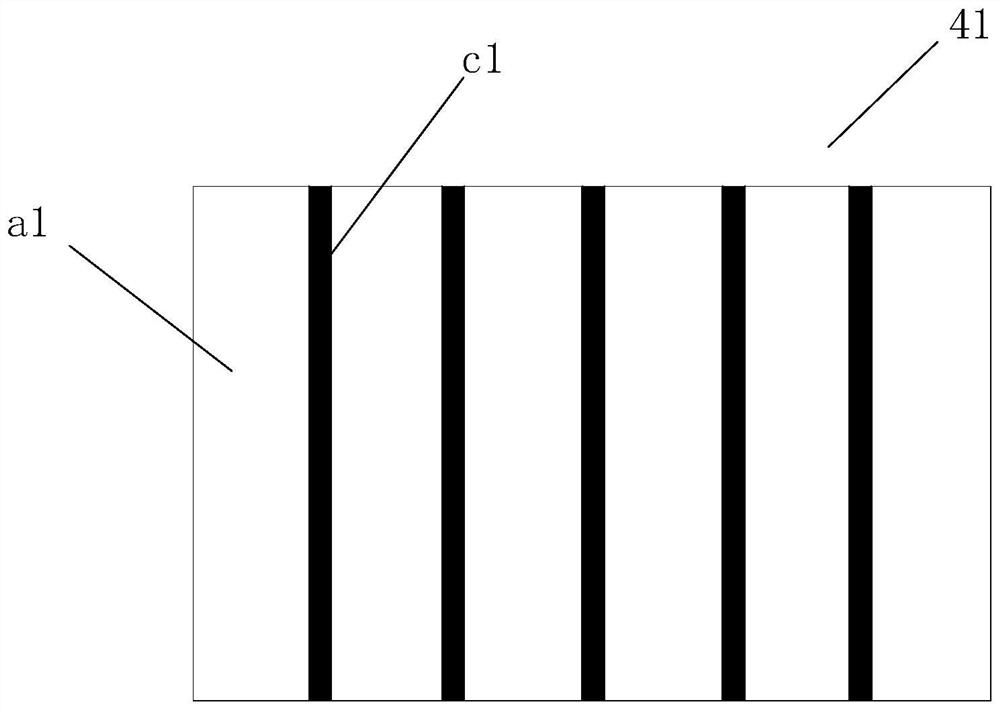

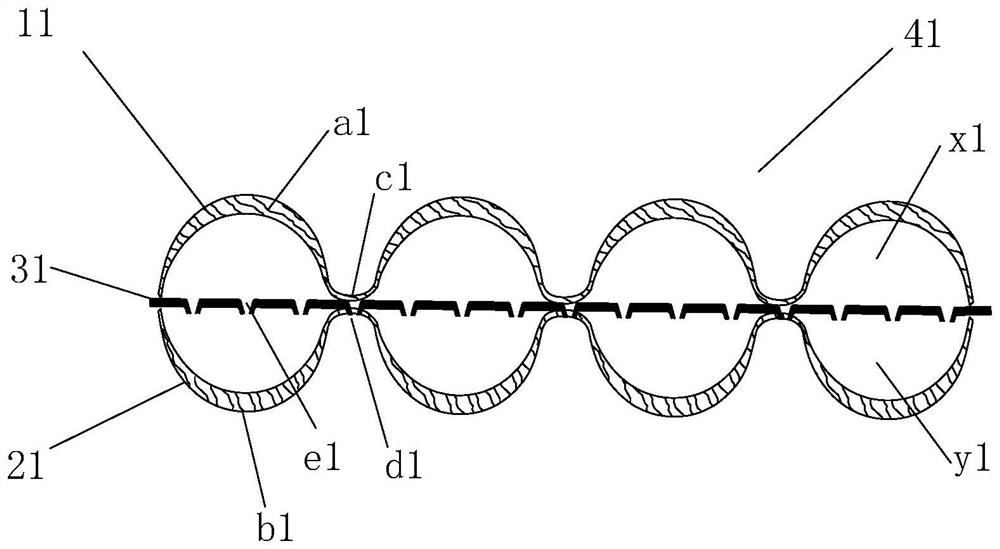

[0105] like Figure 4 Together with figure 1 , figure 2 with image 3 As shown, the permeable elastic composite nonwoven fabric of the first embodiment of the present invention adopts the following method:

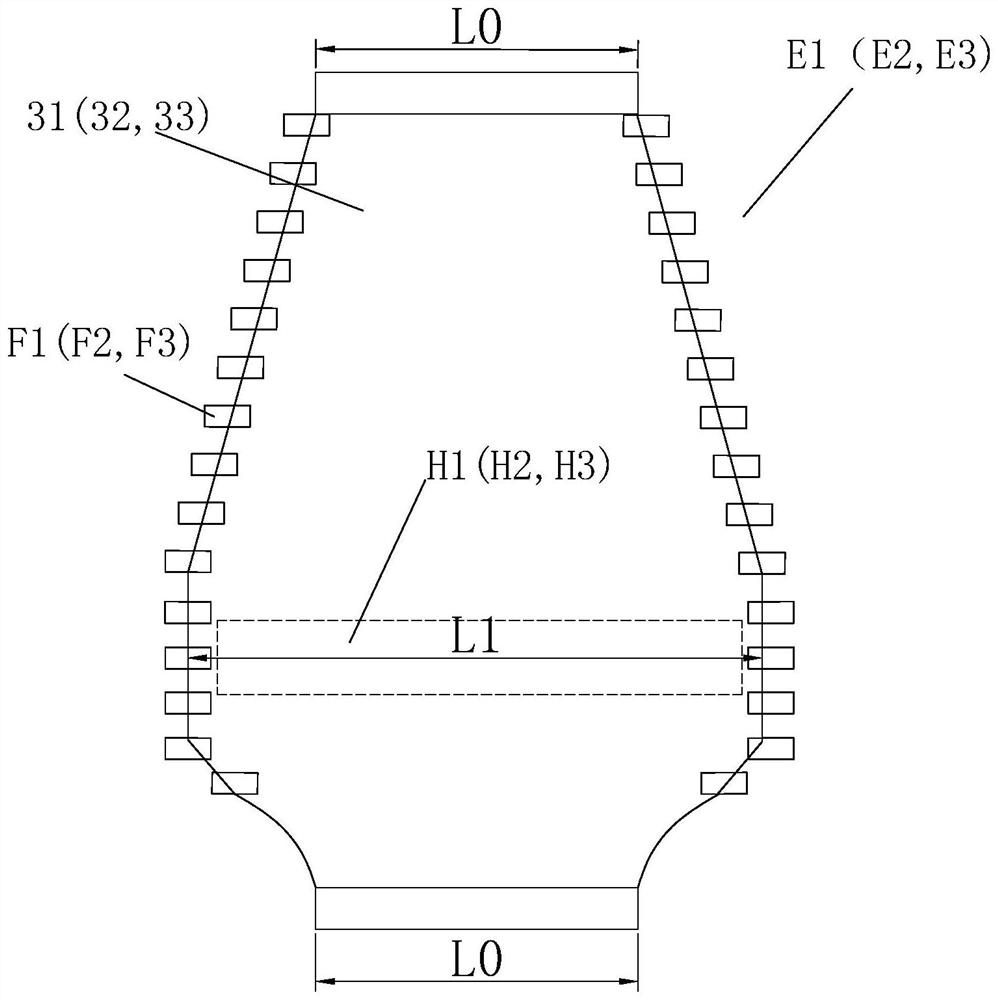

[0106] (1) The elastic film openings, a thermoplastic polychloride elastomer (TPU) is melt extruded extruded into the screw extruder A1; the elastic cast film enters the vacuum opening device, the vacuum open The hole device is composed of a vacuum pump (not marked in the figure), composed of a molding drum B1 coupled to the vacuum pump and a molded web cage C1 located outside the molded drum. When the elastic film enters the vacuum suction D1 of the vacuum opening device, due to internal and external pressure The difference is a plurality of funnel-shaped openings E1, forming a plurality of funnel-shaped openings E1, forming the elastic thin film 31 having the funnel shaped opening E1, wherein: the shape of the funnel-shaped opening E1 and the forming web cage C1 located outsid...

Embodiment 2

[0111] like Figure 5 , Image 6 , Figure 7 ,Cooperate image 3 As shown, the present invention discloses a gas permeable elastic composite nonwoven fabric 42, which consists of a surface layer nonwoven fabric 12, an intermediate layer elastic film 32, and a bottom-layer nonwoven fabric 22, a surface layer. Both the nonwoven fabric 12 and the underlying nonwoven fabric have a plurality of strip-type projections A2, B2, and the recessed regions C2, D2, and the surface layer nonwoven fabric 12 also has an opening structure F2, intermediate The recess-shaped region C2, D2 having a funnel-shaped opening E2, a surface layer nonwoven fabric 12, and a bottom layer-free nonwoven fabric 22, respectively, composite the top of the funnel shaped opening E2 of the intermediate layer elastic film 32. On the surface of the bottom, and the composite position is correspondingly, the surface layer nonwoven fabric 12 and the underlying nonwoven fabric 22 form a strip ventilation passage between the pro...

Embodiment 3

[0118] like Figure 8 , Figure 9 , Figure 10 ,Cooperate image 3 As shown, the present invention discloses a gas permeable elastic composite nonwoven fabric 43, which is formed of a surface layer nonwoven fabric 13, an intermediate layer elastic film 33 and a bottom-layer nonwoven fabric 23, a surface layer Both the nonwoven fabric 13 and the underlying nonwoven fabric have a plurality of striped strip projections A3, B3, and the recessed regions C3, D3, and the surface layer nonwoven fabric 13 and the underlying nonwoven fabric 23 have also have The opening structure F3, G3, the intermediate layer elastic film 33 has a funnel-shaped opening E3, the surface layer nonwoven fabric 13, and the recessed region C3, D3 of the underlying nonwoven fabric 23 composite in the intermediate layer elastic film 33, respectively. The top and bottom of the funnel shaped openings E3 are on the surface, and the composite position is corresponding, the surface layer nonwoven fabric 13 and the underlyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com