Refrigerated cabinet hollow glass door

A glass door and refrigerated cabinet technology, applied in windows/doors, display cabinets, household refrigeration devices, etc., can solve the problems of high energy consumption of products, poor energy-saving effect of glass doors, poor sealing of hollow glass doors, etc., and achieve simplification The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the examples.

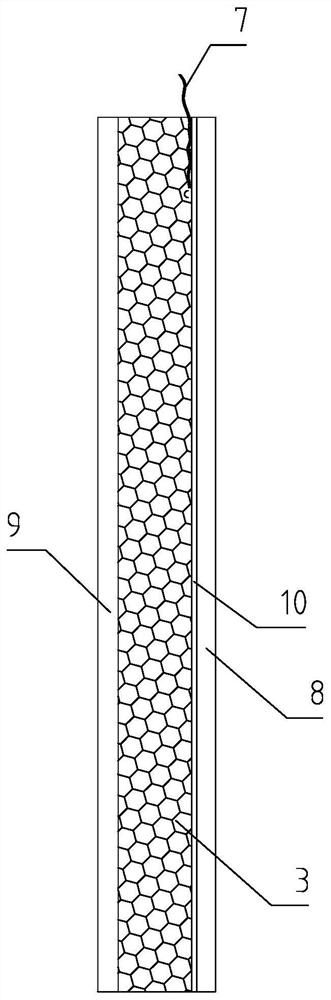

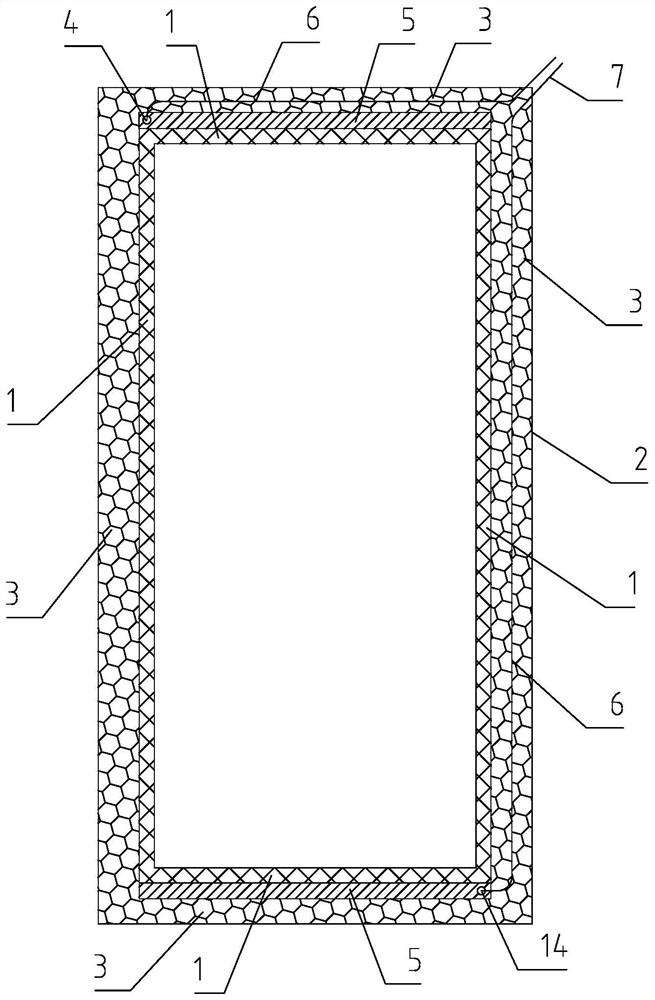

[0050] Figure 1-Figure 28It is an embodiment of a hollow glass door of a refrigerated cabinet and its manufacturing method according to the present invention. It can be seen in the figure that it includes a glass door main assembly 12 and a conductive heating assembly 13. The glass door main assembly 12 includes a coated glass 8, and a coated glass 8 A white glass 9 is provided on one side of the glass, and an inner heat-insulating soft glue 1 is arranged between the coated glass 8 and the white glass 9, and a hollow glass cavity is arranged on the inner side of the inner heat-insulating soft glue 1 between the coated glass 8 and the white glass 9 body 11, the hollow glass cavity 11 is filled with an inert gas; the coated glass 8 includes a conductive coating layer 10 on its inner surface, and the inner heat insulating soft glue 1 is located around the inner surface of the conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com