Hay crushing device and working method thereof

A crushing device and forage technology, which is applied in the direction of drying gas arrangement, drying, dryer, etc., can solve the problems of dry forage not being crushed, evenly crushed, and affecting the effect of animal feeding, so as to prevent agglomeration and increase the range , Improve the effect of crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

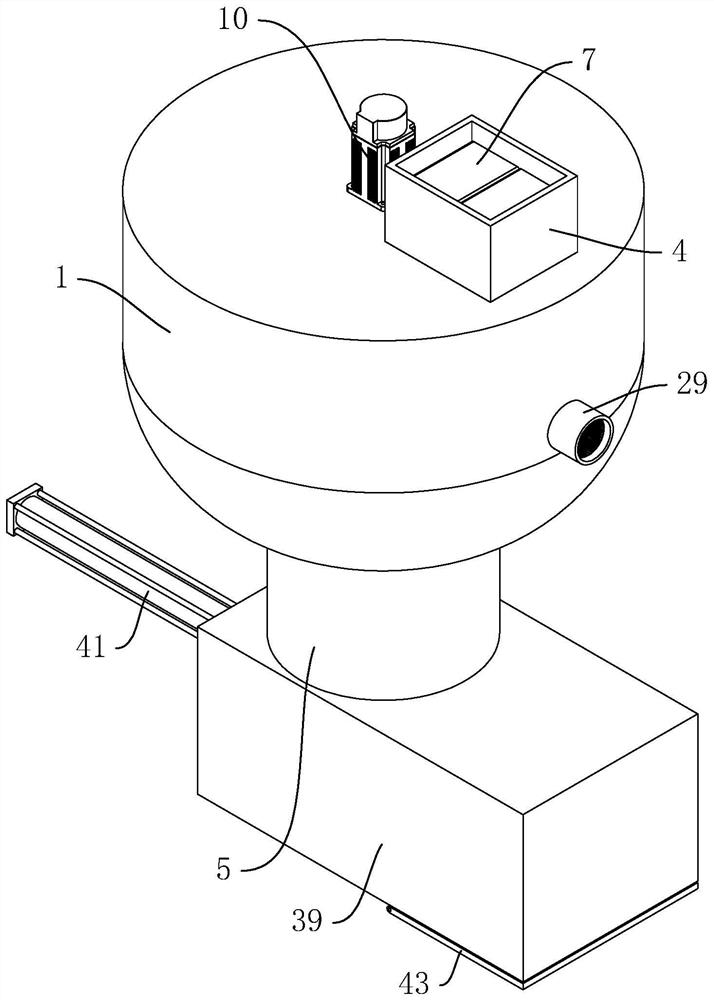

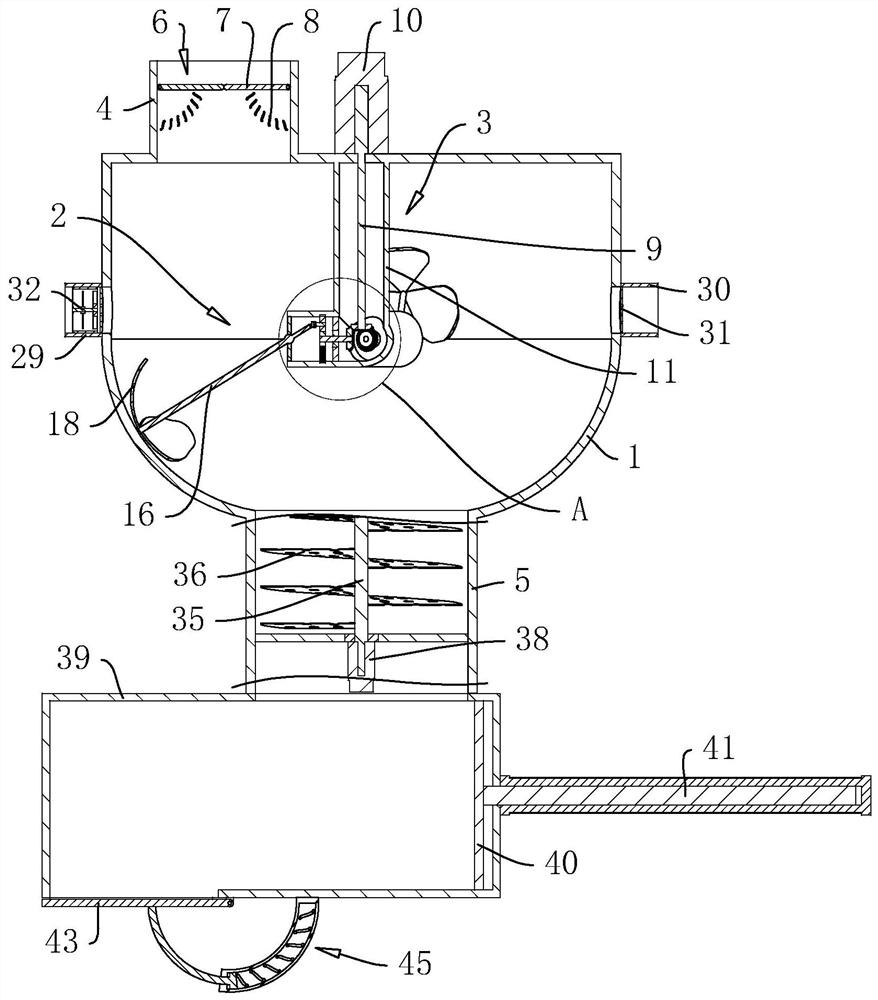

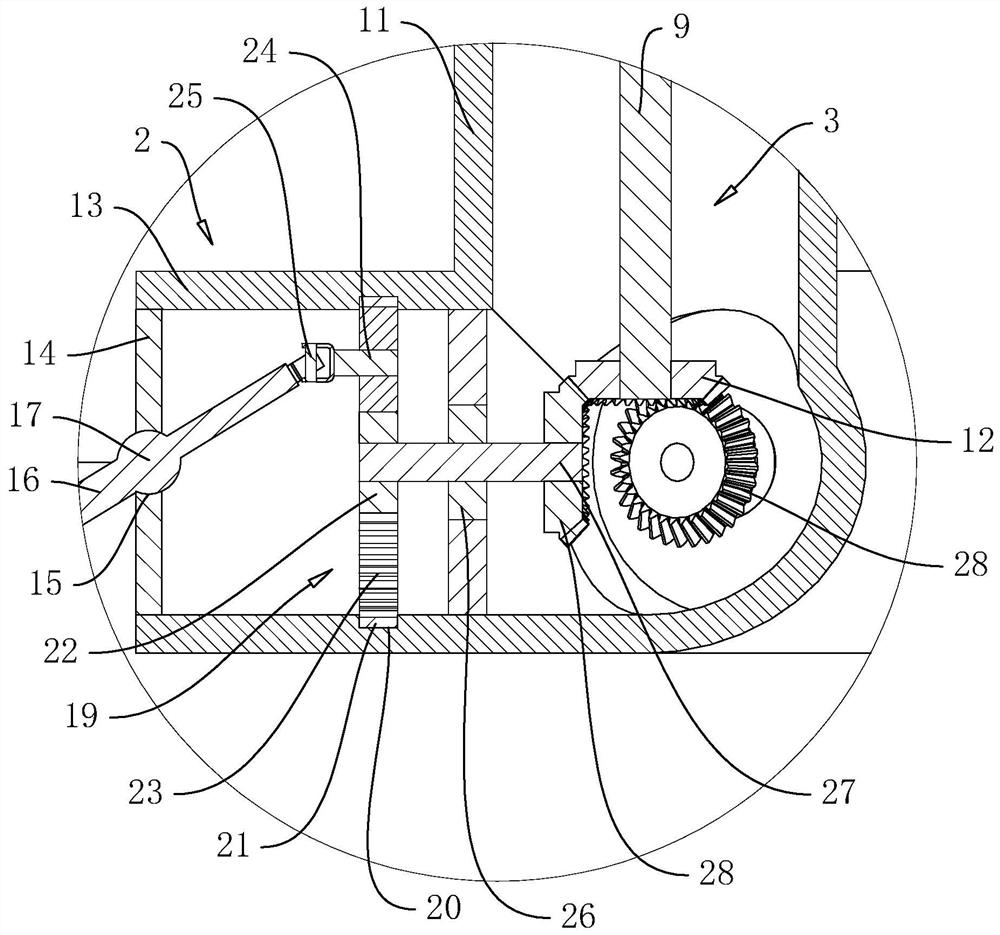

[0047] The following is attached Figure 1-6 The application is described in further detail.

[0048] The present application discloses a dry grass crushing device. refer to figure 1 and figure 2 , a dry grass crushing device includes a crushing box 1, three groups of crushing assemblies 2 arranged in the crushing box 1 and uniformly arranged in a ring shape, and a driving mechanism 3 for driving the crushing assemblies 2, wherein the top of the crushing box 1 and the The bottom is respectively connected with the feed channel 4 and the discharge channel 5, and the upper half of the crushing box 1 is cylindrical, and the lower half is in the shape of a bucket that gradually decreases from top to bottom.

[0049] refer to figure 2 , in order to increase the airtightness in the crushing box 1, the inner wall of both sides opposite to the feeding channel 4 is symmetrically provided with a closing member 6, and the closing member 6 includes a door panel 7 hinged in the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com