Analysis method for gold content of gold-containing ore sample

An analysis method and technology for gold content, applied in the field of analysis of gold content of gold-bearing ore samples, can solve the problems of scattered distribution, inaccurate detection results, and low gold content of gold-bearing ore samples, so as to reduce data fluctuation and expand sampling range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

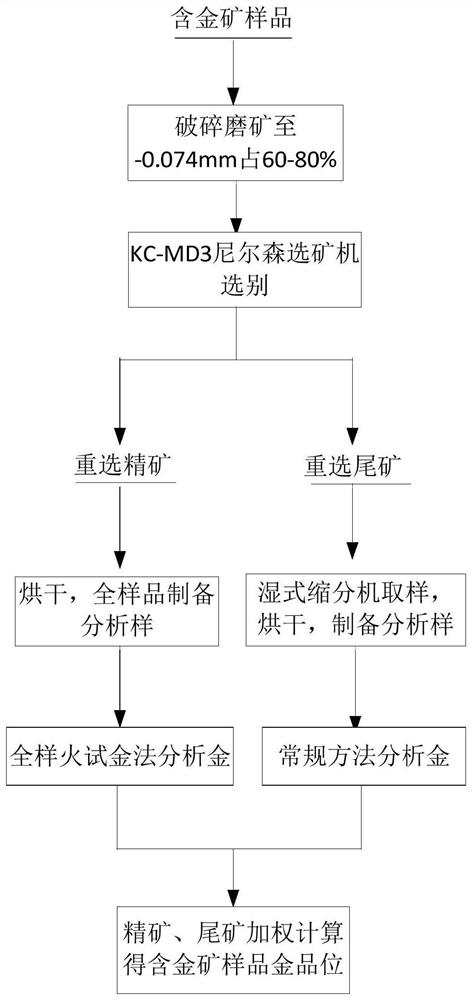

Method used

Image

Examples

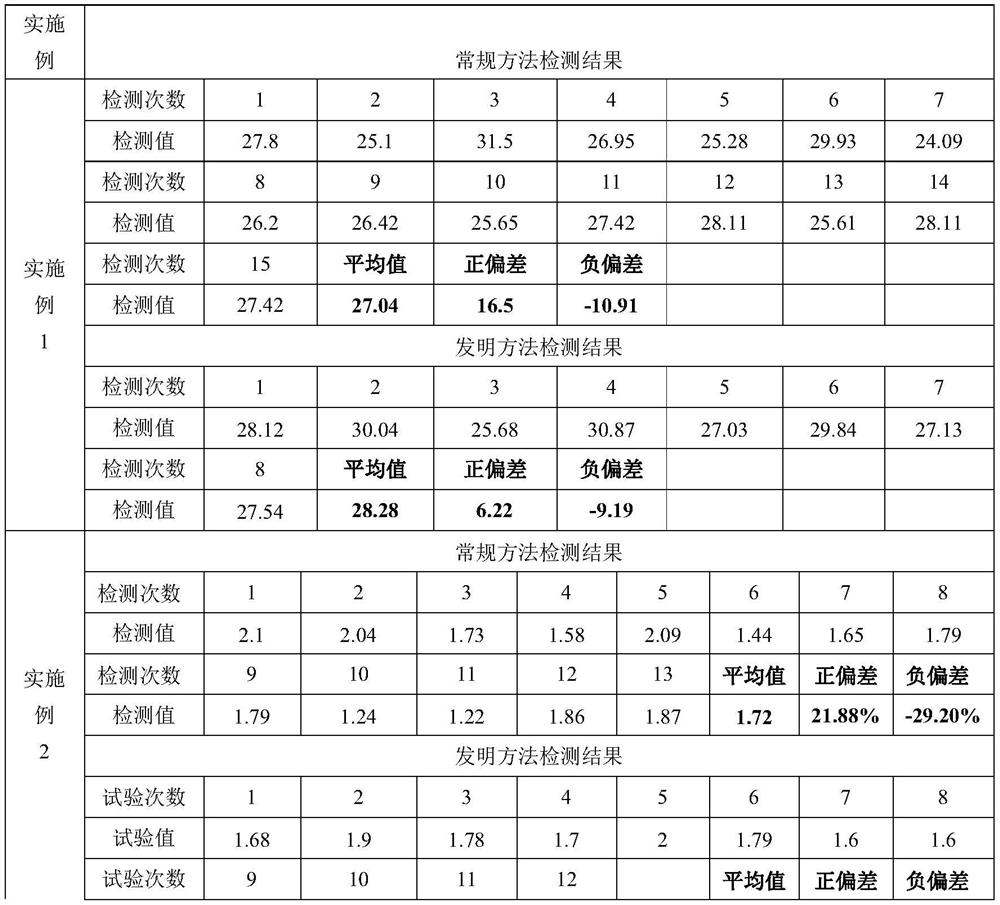

Embodiment 1

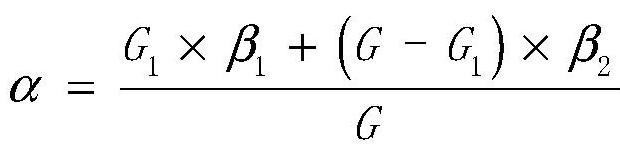

[0031] In a sulfide-poor gold ore, except for the precious metal natural gold, the content of other metal minerals is extremely low. The analysis sample was prepared by conventional methods, and the gold content was tested for 15 times. The gold content was between 24.09-29.92g / t Between them, the average was 27.04g / t, with a deviation of -10.91% to 16.50%. Adopt the method of the present invention, 1-7kg arbitrary weight sample grinds ore respectively to account for 80% to -0.074mm, after the sorting of Nielsen separator, gravity separation concentrate and gravity separation tailings are according to formula α=(G 1 *β 1 +(G-G 1 )*β 2 ) / G, 8 tests show that the gold content is between 25.68-30.87g / t, the average grade is 28.28g / t, and the deviation is -9.19% to 6.22%. The gold-bearing ore samples should be used to analyze the samples The preparation method reduces the deviation of the gold analysis results of the gold-bearing ore.

Embodiment 2

[0033] In a certain polysulfide gold ore, in addition to the precious metal natural gold, the ore has a high sulfur content. The analysis sample was prepared by a conventional method. After repeated 13 times to detect the gold content, the gold content was between 1.22-2.1g / t. The average was 1.72g / t with a variance of -29.20% to 21.88%. Adopt the method of the present invention, 1-7kg random weight sample grinds ore respectively to account for 50% to -0.074mm, after being sorted by Nielsen separator, gravity separation concentrate and gravity separation tailings are according to formula α=(G 1 *β 1 +(G-G 1 )*β 2 ) / G, 12 tests show that the gold content is between 1.6-1.98g / t, the average grade is 1.78g / t, and the deviation is -10.28% to 12.15%. The gold-bearing ore sample should be used to analyze the sample With the preparation method, the deviation of the gold analysis result of the gold-bearing ore is obviously reduced.

Embodiment 3

[0035] In a gold-bearing polymetallic ore, in addition to the precious metal silver-gold ore and natural gold, the metal minerals pyrite, galena and sphalerite are relatively high. The analytical sample was prepared by the conventional method, and the gold content was tested 21 times. The gold content was between 5.74-9.48g / t, with an average value of 7.43g / t and a deviation of -22.76% to 37.26%. Adopt the method of the present invention, 1-7kg arbitrary weight sample grinds ore respectively to -0.074mm and accounts for 75%, after sorting through Nelson separator, gravity separation concentrate and gravity separation tailings are according to formula α=(G 1 *β 1 +(G-G1 )*β 2 ) / G, 13 tests show that the gold content is between 6.99-10g / t, the average grade is 8.59g / t, and the deviation is -18.60% to 16.45%. With the preparation method, the deviation of the gold analysis result of the gold-bearing ore is obviously reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com