Prestressed PC construction method combined steel pipe pile foundation pit supporting structure and construction method thereof

A technology of combining steel pipes and supporting structures, which can be used in basic structure engineering, excavation, sheet pile walls, etc., and can solve problems such as extending the construction period and increasing the project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

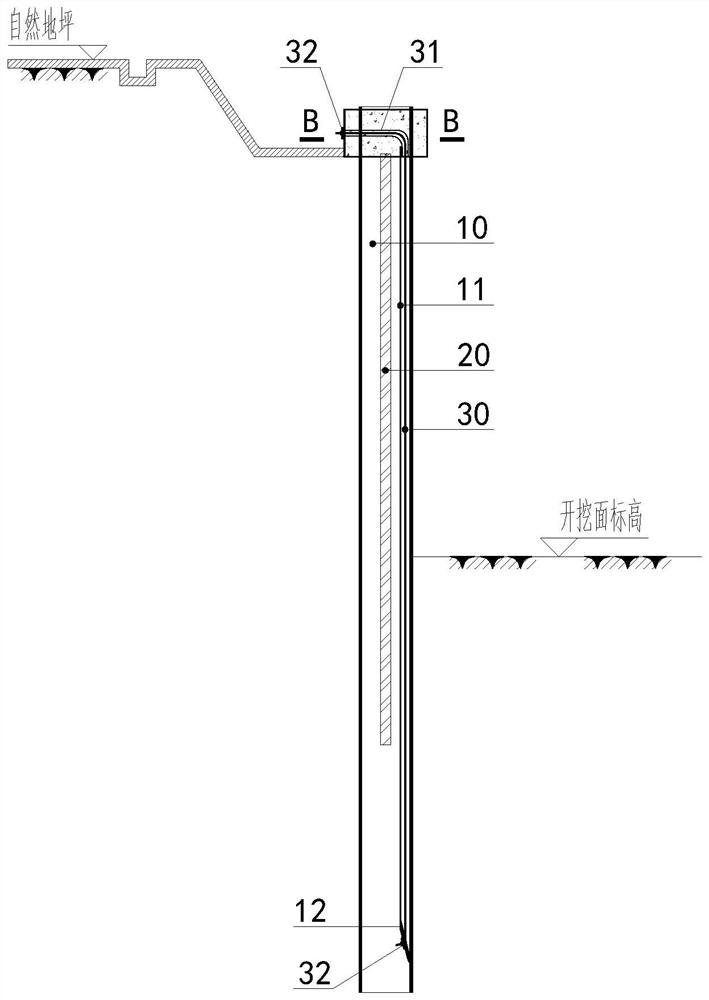

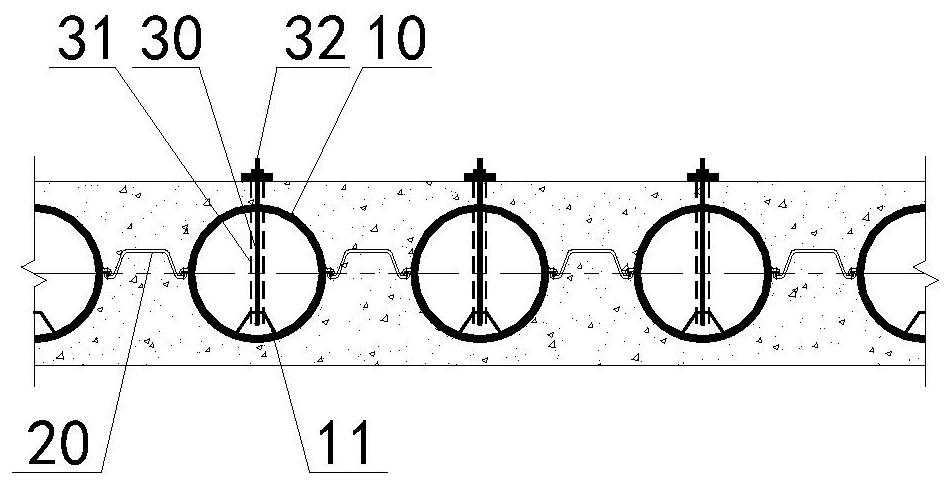

[0043] combine Figure 1 to Figure 6 Illustrate the prestressed PC engineering method combined steel pipe pile foundation pit support structure of the present embodiment, it comprises:

[0044] A row of steel pipe piles 10 is composed of a plurality of steel pipe piles 10 arranged at intervals along the excavation surface of the foundation pit, and a fixed end anchor is arranged at the bottom of the row of steel pipe piles 10 near the excavation surface of the foundation pit. Tool 12;

[0045] Multiple Larsen steel sheet piles 20, two adjacent steel pipe piles 10 are locked and connected by a Larsen steel sheet pile 20, that is, the steel pipe piles 10 and Larsen steel sheet piles 20 are connected alternately in turn to form a whole steel continuous wall body;

[0046] The top beam 40 is horizontally arranged on the top of a row of steel pipe piles 10;

[0047] A plurality of prestressed steel strands 30, one end of the prestressed steel strands 30 is anchored to the fixed-...

Embodiment 2

[0054] Different from Example 1, as Figure 1 to Figure 4 As shown, the prestressed PC construction method combined steel pipe pile foundation pit support structure also includes a groove 11 vertically arranged in the steel pipe pile 10 on the side close to the excavation surface of the foundation pit, and the cross section of the groove 11 is "C" It is fixed on the inner wall of the steel pipe pile 10 and together constitutes the vertical channel of the prestressed steel strand 30, the top of the groove 11 is against the top beam 40, the bottom of the groove 11 is against the fixed end anchorage 12, and the prestressed steel strand 30 penetrates into the groove 11, which can avoid the adverse effect of the soil on the prestressed steel strand 30 during the construction of the steel pipe pile 10.

[0055] Please continue to refer figure 1 with Figure 4 , the fixed end anchor 12 is a steel plate set at an angle with the inner wall of the steel pipe pile 10, the thickness of ...

Embodiment 3

[0058] combine Figure 7 to Figure 9 Illustrate the prestressed PC construction method combined steel pipe pile foundation pit support structure of this embodiment, which is different from Embodiments 1 and 2 in that it includes:

[0059] Two rows of steel pipe piles 10 arranged in parallel and at intervals are the first row of steel pipe piles close to the excavation surface of the foundation pit, and the second row of steel pipe piles away from the excavation surface of the foundation pit;

[0060] A plurality of Larsen steel sheet piles 20, two adjacent steel pipe piles 10 in the first row of steel pipe piles are locked and connected by at least one Larsen steel sheet pile 20, that is, the steel pipe piles 10 and Larsen steel sheet piles 20 are connected alternately in sequence. An integral steel continuous wall, each steel pipe pile 10 is provided with a fixed end anchor 12 at the bottom of the inner wall on the side close to the foundation pit;

[0061] Two capping beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com