Device for corroding silicon carbide wafer by alkali steam

A technology of silicon carbide and alkali steam, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficult handling of alkaline steam and high temperature, and achieve the goals of reducing heat loss, rapid response, and guaranteed corrosion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

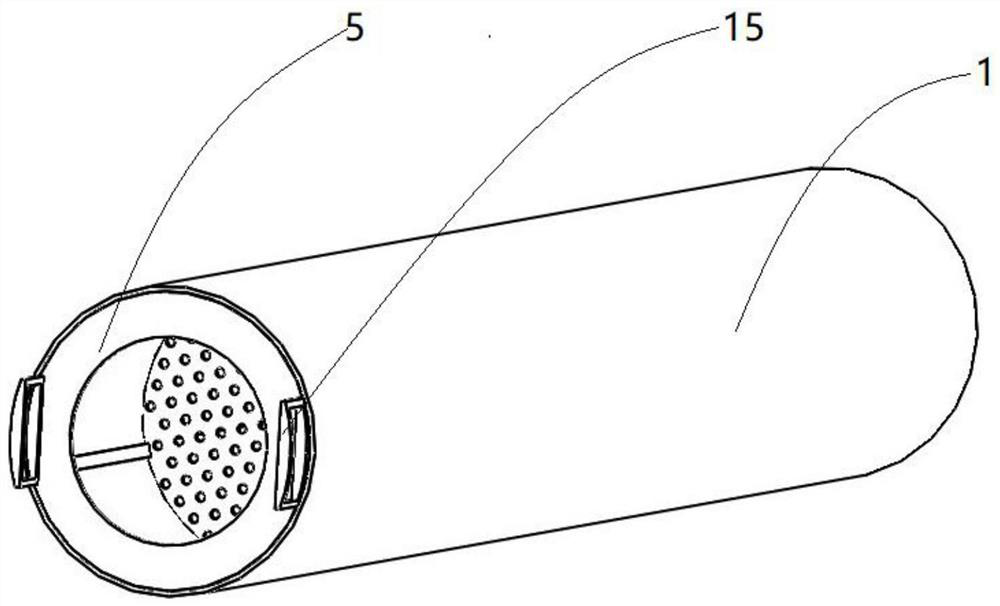

[0064] The difference between this embodiment and Embodiment 1 is that the reaction component 11 is only provided with an opening at one end, and a single pipe plug 5 is used to seal the opening.

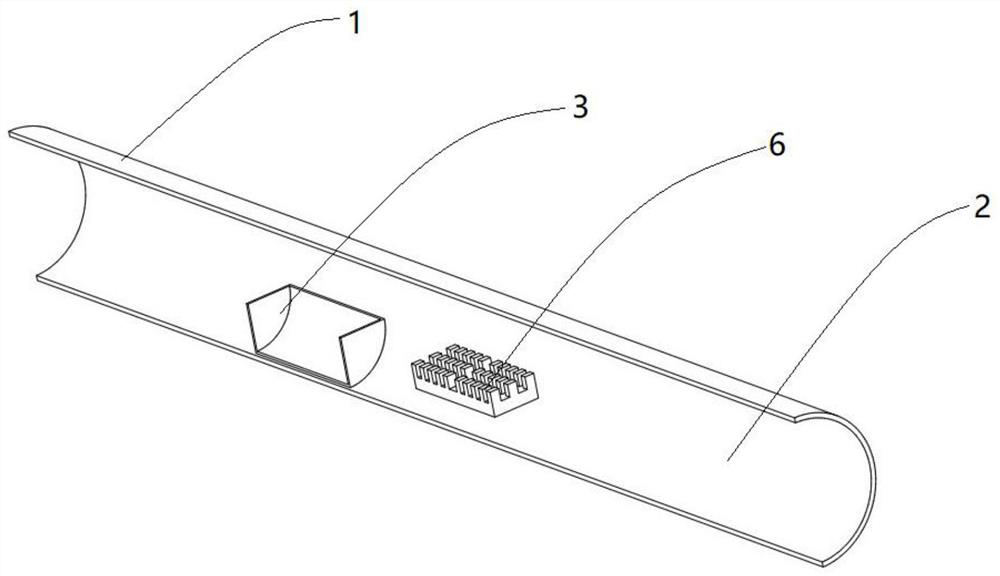

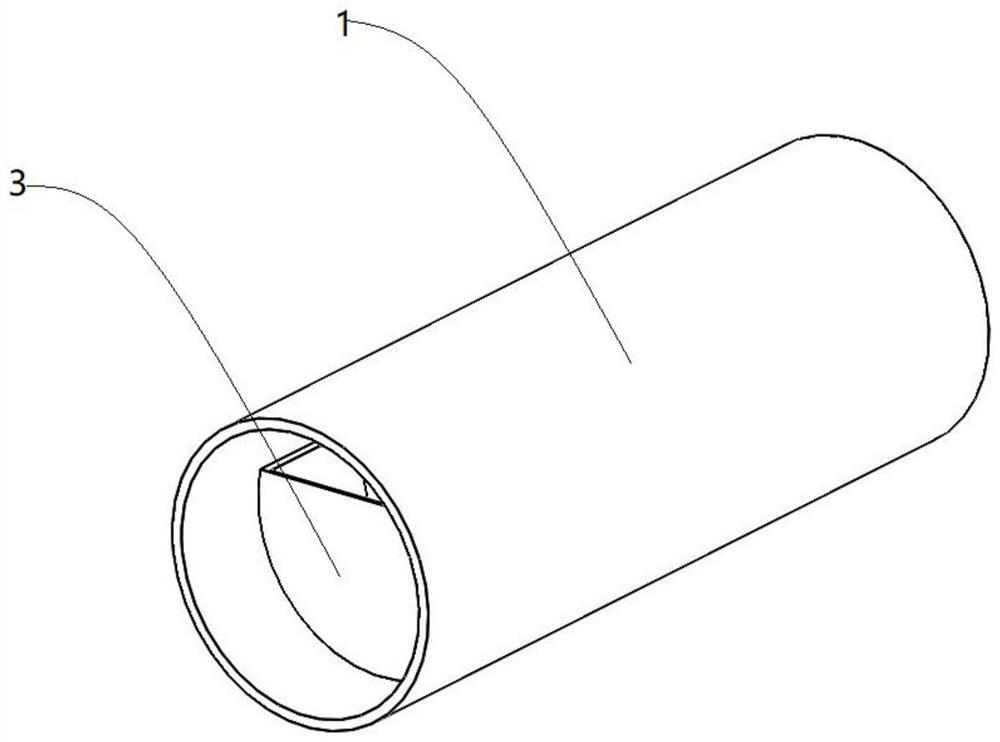

[0065] A method of use of the present invention: first place a plurality of silicon carbide wafers to be etched in the slot 7 of the silicon carbide wafer mounting part 6, and put the silicon carbide wafer mounting part 6 into the steam chamber of the reaction part 1 2. Inject the alkaline solution into the corrosion-resistant boat 3 and put it into the steam chamber 2, and fill the condensation zone 8 and the reaction zone 9 of the pipe plug 5 with corrosion-resistant porous insulation materials and porous insulation materials that are easy to react with alkaline steam, respectively Then the pipe plug 5 is installed on the reaction part 1, thereby sealing the reaction part 1; finally, the reaction part will be placed in the tube furnace, and the tube furnace is opened, and the tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com