Whole-layer stacking clamp

A palletizing and fixture technology, applied in the field of palletizing equipment and fixtures, can solve the problems of lack of packaging boxes, inability to meet the high-speed production requirements of production lines, low production efficiency, etc., to reduce storage and transportation costs, compact structure, and easy to grasp. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

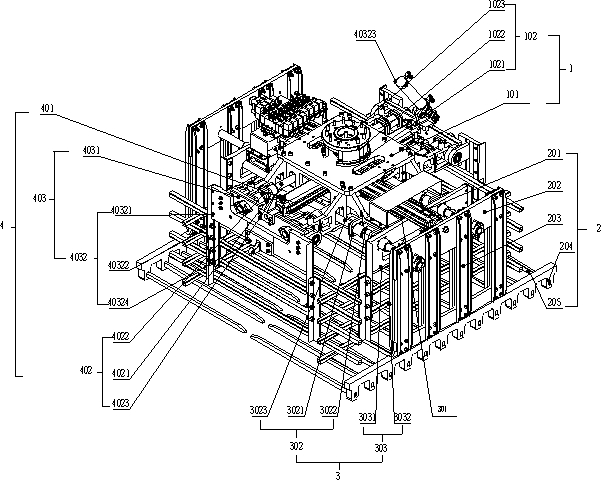

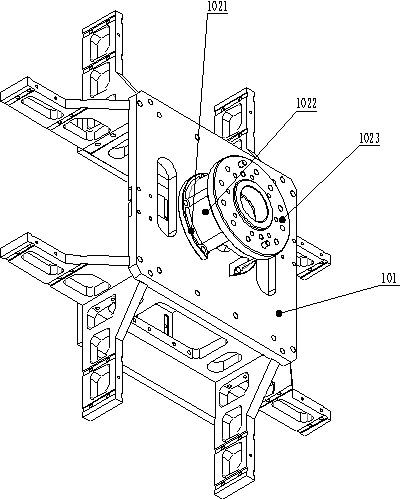

[0039] Whole layer palletizing clamp assembly includes a top plate 1, at least a full set of layer stacking bracket disposed opposite the lever assembly 2, at least one set stamp clamp slide assembly side plate 3 and at least one set of oppositely disposed opposite flip-folder setting stamp the slide plate assembly 4 side;

[0040] In a full set of layer stacking bracket disposed opposite the lever assembly 2, a set of stamp clamp slide assembly side plate 3 and a set of flip-stamp clamp disposed opposite sides of the slide plate assembly disposed opposite elucidated Example 4:

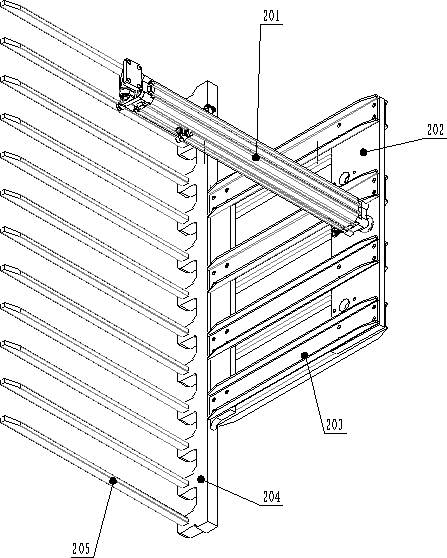

[0041] Specifically, each set of said stamp clamp slide assembly side plate 3 and the flip-stamp clamp slide assembly 4 opposite the side plate, can be shaped stamp up areas, for transverse and / or longitudinal layers of the entire code-shaped stamp together;

[0042] Specifically, the whole layer palletizing catcher rod assembly 2, is used to form the finished stamp for the whole layer shaped stamp inse...

Embodiment 2

[0071] This protocol is provided with only a set of relative set of clamp sliding edge plate assemblies 3 and a set of relative set of flip clamp sliding edge plate assemblies 4, only for implementing the finishing of the entire material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com